It is possible to enhance product quality by varying the blade angle and material according to the characteristics of the cut material!

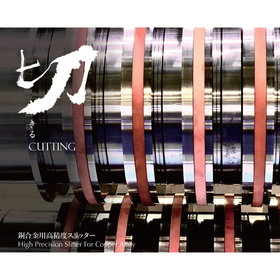

Our company performs slitting processing using a slitter. A slitter is a machine that cuts materials such as paper, non-woven fabric, film, adhesive tape, and metal foil, which are rolled up (raw materials), into desired widths using rotating blades while rewinding them, and then finishes them back into rolls. We have established equipment environments for each material, including paper, film, and others, to carry out processing under optimal conditions. We also possess processing machines for traverse processing, sheet (thick) slitting, and materials for metal foil and RFID. [Equipment Owned (Partial)] ■ Paper - Micro slitter - Single-axis slitter - Double-axis slitter - Wide, large slitter *For more details, please refer to the PDF document or feel free to contact us.

Inquire About This Product

basic information

【Other Equipment (Partial)】 ■ Films - Micro slitter - Traverse processing - 2-axis slitter - Sheet slitter ■ Others - For metal foil and RFID - For batteries - Adhesive products *For more details, please refer to the PDF document or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

For more details, please refer to the PDF document or feel free to contact us.

catalog(2)

Download All CatalogsCompany information

Since our establishment in 1964 as a specialized manufacturer of paper processing, we have always considered the feelings of our customers and focused on the usability of our products, continuously pursuing the ease of use of paper and the limitless possibilities of paper. As times change and customer needs evolve, we have expanded our offerings to include various materials such as paper, film, non-woven fabric, and others. We process a variety of materials (paper, film, adhesive tape, non-woven fabric, etc.). We offer various processing options including slitting, cutting, die-cutting, laminating, and coating, as well as processing that includes material procurement, contract processing, and material sales. We have established both general and cleanroom environments, and depending on the processing content, materials, and required quality, we respond with the optimal environment and equipment from approximately 100 units. We have built a functional production system that responds promptly to the flow of the times, so please feel free to contact us.