Cutting is possible for hexagonal bars, flat bars, and pipes made of copper and copper alloys (including brass)!

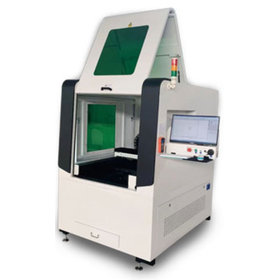

At Arsys Co., Ltd., we handle circular saw cutting machines for copper alloys. The undercut type has a structure that minimizes the scattering of chips. The main body of the cutting machine is designed with rigidity (vibration prevention). Additionally, the saw blade is equipped with a vibration control device to mitigate vibrations. Please feel free to contact us when you need assistance. 【Specifications (partial)】 ■ Model: Undercut type / Circular saw cutting machine (straight return type) ■ Cutting range: MAX W300mm × H120mm ■ Cutting materials: Copper and copper alloys ■ Cutting dimension: φ810mm ■ Cutting speed: 80–350m/min (variable by inverter) *For more details, please refer to the PDF document or feel free to contact us.

Inquire About This Product

basic information

【Other Specifications】 ■ Spindle speed: 30 to 138 r.p.m (variable via inverter) ■ Spindle power: 11 kW (INV) ■ Feed speed: 0 to 5 m/min ■ Return feed speed: 12 m/min ■ Feed drive: 1.0 kW AC servo motor ■ Ancillary equipment ・ Complete set of conveyors for the input and output sides of the cutting machine ・ Complete set of conveyors inside the cutting machine ・ Complete dust collection and air conveyance system for chips *For more details, please refer to the PDF document or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

For more details, please refer to the PDF document or feel free to contact us.

catalog(1)

Download All CatalogsCompany information

Alcis Co., Ltd. is a comprehensive engineering manufacturer of equipment related to aluminum extrusion, surface treatment, rolling, and processing. To meet the aluminum processing industry's demand for diverse and small-lot production, we will continue to develop various technologies and pursue growth.