Proactive response to increased tariffs! Proposal for "total logistics cost reduction" through packaging improvements.

Current necessary measures aim for overall optimization from packaging materials to achieve 'total logistics cost reduction'.

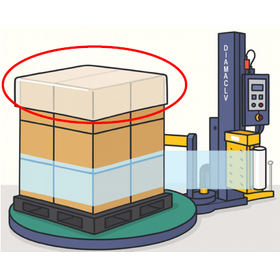

Our company is celebrating its 70th anniversary this year. Since our founding, we have been working on converting wooden boxes into cardboard, and based on market needs, we have designed and developed reinforced cardboard "Navi Ace" and cardboard pallets "Navi Palette." These designs have been adopted by major companies, and we have received a total of 52 awards in competitions such as the Japan Packaging Contest. In January 2025, the Trump administration was established in the United States, imposing tariffs of 10% on China and 25% on Mexico and Canada. The increase in tariff items raises concerns about a trade war in industries such as automobiles and metals. However, it is difficult to immediately pass on these costs or raise product prices, and there are concerns about a decrease in sales volume. Therefore, we propose "total logistics cost reduction" with Navi Ace. By leveraging the strength and lightness of our reinforced cardboard "Navi Ace" to design packaging materials unique to your company, we aim to achieve overall optimization in storage, packing, transportation, and handling, leading to a reduction in overall logistics costs. However, verifying such designs inevitably takes time. To proactively address the impending increase in tariffs, would you like to work together on improvement activities? Please feel free to contact us through inquiries.

Inquire About This Product

basic information

Naviace Corporation is a reinforced cardboard manufacturer specializing in packaging design for automotive parts, metal and chemical materials, and precision instruments. We believe that promoting "total logistics cost reduction" can also lead to carbon neutrality. Specifically: 1. Cardboard has a low CO2 emission as a material, and switching from wood, plastic, and metal packaging can reduce CO2 emissions. 2. Cardboard is a highly versatile material in design, allowing for improvements in transportation efficiency, such as compacting packaging, which can further reduce CO2 emissions. 3. From the above, by reviewing packaging design and aiming for material replacement and improved transportation efficiency, we contribute to reducing our customers' CO2 emissions. We have extensive experience with material manufacturers in steel, non-ferrous metals, chemicals, and more, whose total product weight exceeds 500 kilograms. Please feel free to contact us.

Price information

Prices vary based on specifications, lot, and delivery conditions. Please feel free to contact us.

Delivery Time

※From specification decision, the first time is 10 business days, and repeat is 7-10 business days (varies depending on specifications).

Applications/Examples of results

■Awards in the Japan Packaging Contest / Organized by the Japan Packaging Technology Association ※Some parts omitted 2023: Chairman's Award from the Japan External Trade Organization (JETRO) "Achieved significant increase in load capacity! Cardboard bandless container" 2021: Large and Heavy Goods Packaging Division Award "Consolidated packaging for inter-factory transport parts" 2020: Large and Heavy Goods Packaging Division Award "Complete cardboard packaging for self-propelled radio-controlled sprayers" 2019: Logistics Award "Complete cardboard packaging for gear grinding wheels" 2019: Award from the Director of the Manufacturing Industries Bureau, Ministry of Economy, Trade and Industry "Transition from wooden frame packaging to complete cardboard packaging" 2018: Logistics Award "Development of Slip Master" 2018: Large and Heavy Goods Packaging Division Award "Suspended packaging for roll products" 2017: Logistics Award "Suspended packaging for rolls" 2016: Division Award "Complete cardboard packaging for aircraft seats" 2011: Chairman's Award from the Japan Chamber of Commerce and Industry "Complete cardboard packaging for large copiers" 2009: Minister of Economy, Trade and Industry Award (highest honor) "Packaging of 40 chairs for export"

catalog(6)

Download All Catalogs

![Packaging Example | Starter Assembly Packaging | Naviece × Major Automotive Parts Manufacturer [Cardboard Packaging]](https://image.mono.ipros.com/public/catalog/image/01/1b0/477710/IPROS56976148585803432845.jpeg?w=120&h=170)

Company information

Naviace Co., Ltd. celebrated its 70th anniversary in January 2025. In August 2023, the group company "Naviace Kanto Co., Ltd." completed a new factory in Itakura Town, Ora District, Gunma Prefecture (10 minutes from the "Tatebayashi IC" on the Tohoku Expressway). The facility has expanded its production capabilities for reinforced cardboard "Naviace" and cardboard pallets "Navi Palette" and has relocated. This strengthens the supply capacity from the Kanto region to the Tohoku region, establishing a more unified sales and production system within the group. ■ Business Overview Manufacturing and sales of reinforced cardboard "Naviace/Naviace Plus" and cardboard pallets "Navi Palette." Using these materials, we are working with our customers to streamline logistics across various industries, from automotive parts and machinery to electronics, chemicals, and food sectors. ■ Company Overview Company Name: Naviace Co., Ltd. (Formerly Nakatsugawa Packaging Industry Co., Ltd.) Capital: 100 million yen ■ Locations Headquarters: Kasugai City, Aichi Prefecture Nakatsugawa Factory/Sales Office: Nakatsugawa City, Gifu Prefecture Kameyama Factory/Sales Office: Kameyama City, Mie Prefecture Kakegawa Factory/Sales Office: Kakegawa City, Shizuoka Prefecture Kanagawa Sales Office: Atsugi City, Kanagawa Prefecture Naviace Kanto: Itakura Town, Ora District, Gunma Prefecture

![[Improvement Case] Roll Products Suspended - E-BOX | Navias × Nitto Denko](https://image.mono.ipros.com/public/product/image/4b4/2000681187/IPROS08157110457124561418.png?w=280&h=280)

![[Pallet Management System] Data management with QR codes and terminals / Prevents loss!](https://image.mono.ipros.com/public/product/image/6c3/2000702555/IPROS09922554958312466508.jpeg?w=280&h=280)

![[Pallet Management System] Prevents Loss and Supports Maintenance Inspections](https://image.mono.ipros.com/public/product/image/9ac/2001530998/IPROS6194396489798150168.jpg?w=280&h=280)