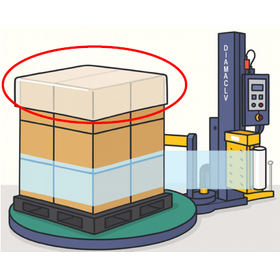

Domestic production, carefully selected materials: What is the durability of the anti-collapse band?

Sustained quality, protecting your products with Japanese craftsmanship. The continuously chosen anti-collapse band.

Our company's load securing band products have received inquiries from various companies as part of decarbonization efforts such as GX (Green Transformation). However, some customers have questions regarding durability and lifespan. The main body of our bands is made of highly abrasion-resistant nylon (with some types made of PP). Generally, the abrasion resistance ranks as follows: "Nylon > Polyester > PP (Polypropylene)." Our products are carefully crafted one by one by skilled artisans in our factory. While the lifespan can vary significantly depending on the usage environment, we typically design our products with a lifespan of "3 to 5 years." Some of our customers have reported using them for over 15 years. As we promote GX, switching from stretch film to cheaper alternatives (such as polyester products) may lead to unnecessary costs if replacements are needed in a short period. While there will be some initial investment, why not start small with a few units?

Inquire About This Product

basic information

Material: Made of nylon Reduces tearing due to friction and boasts high durability.

Price information

Please contact us.

Delivery Time

Applications/Examples of results

"Anti-collapse bands," essential logistics materials for GX, such as the plastic waste problem and decarbonization. Our products are "made in Japan," allowing for stable supply without being affected by overseas markets or situations. Since 2020, even during the paralysis of overseas logistics (mainly in Asia) due to the spread of the COVID-19 virus, we have been able to deliver to our customers with minimal impact. With over 30 years of proven performance since our sales began in 1990, we have gained the support of many customers.

Detailed information

-

Our employees are performing sewing processing in-house. *Made in Japan*

-

Our products are mainly made of nylon. As shown in the material comparison, the anti-collapse band products significantly affect wear resistance during long-term use.

catalog(4)

Download All Catalogs

![[Labor-saving and Time-saving] Load-shifting Prevention Band - "Hitorimaki" Packaging Material that Can Be Wrapped by One Person - Cost Reduction - Environmental Issue Resolution](https://image.mono.ipros.com/public/catalog/image/01/2b1/657709/IPROS16617403577569107817.jpeg?w=120&h=170)

Company information

Our company's load securing band products were launched in 1990, pioneering the industry, and have been well-loved for many years. We now offer a wide variety of options, replacing traditional stretch film used for load securing with reusable bands, contributing to cost reduction, improved work efficiency, and addressing environmental issues by reducing plastic waste. For requests beyond standard products, we can accommodate custom orders starting from one piece or one roll. Furthermore, most of the materials used in our load securing band products are "Made in Japan," ensuring high quality and stable supply by using carefully selected materials manufactured domestically. Additionally, through the manufacturing and sales of load securing bands, we promote the SDGs "12 Responsible Consumption and Production" and "13 Climate Action," aiming to secure sustainable production and consumption patterns. Our goal is to significantly reduce waste generation through prevention, reduction, recycling, and reuse. As a manufacturer's agent, we also offer a wide range of packaging materials and equipment, such as packaging tape and cushioning materials, to solve any issues you may encounter in your packaging and shipping operations.

![[Packaging Material] Eco-friendly load securing band "Palemaki" GX promotion cost reduction](https://image.mono.ipros.com/public/catalog/image/01/746/657714/IPROS73109364080407149030.jpeg?w=120&h=170)

![[New Product] Palemaki ECO, Hitorimaki ECO (Recycled Material Specification)](https://image.mono.ipros.com/public/product/image/554/2001527268/IPROS5066036687282365282.jpg?w=280&h=280)

![Stretch Film "Komaki" [Industry First! Optimal for ECO and Work Efficiency!]](https://image.mono.ipros.com/public/product/image/474/2000317425/IPROS17167699807860247107.jpeg?w=280&h=280)