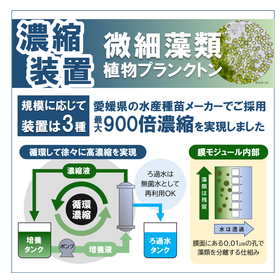

Ultrafiltration membrane system for the concentration of microalgae and phytoplankton.

MSS Series

Adopted by a fishery seed manufacturer! Achieving up to 900 times concentration with UF membrane equipment.

The "MSS Series" is a simple device equipped with a single hollow fiber UF membrane module. The application for concentrating microalgae and phytoplankton separates algae from the culture water through the 0.01 µm pores in the hollow fiber membrane, thereby concentrating the algae. The cross-flow filtration method, which circulates the culture solution, minimizes damage to the algae and achieves high concentration. The device is designed for seawater applications and can be selected from three models based on processing capacity. ★Processing tests with culture solutions are available on the official website★ Contract testing, sale of small test modules, and rental of testing equipment 【Effective Separation and Concentration of Algae】 ■ Minimal damage to algae and stable quality ■ UF membrane is less prone to clogging due to the cross-flow filtration method ■ Energy consumption is about half compared to centrifugation ■ Continuous processing and automation of operation are possible ■ Filtrate can be reused as sterile water ■ Membrane modules can be selected from cellulose acetate (CA) membranes and polyethersulfone (PES) membranes 【Differences in Membrane Types】 The highly hydrophilic CA membrane is less prone to fouling and is effective for long-term operation. The PES membrane has high initial permeability and is suitable for situations where quick processing is desired. *Please feel free to contact us for more details.*

Inquire About This Product

basic information

For detailed specifications of each device, please contact us via our website. ■Product Lineup (1) MSS-F20-PM Device dimensions: W1380×D700×H2113mm Raw water flow rate: 6.7–13.3㎥/hr Filtration flow rate: 500L/hr or more Minimum operating liquid volume: 30–40L (2) MSS-F10-PM Device dimensions: W915×D651×H1980mm Raw water flow rate: 1.9–3.8㎥/hr Filtration flow rate: 150L/hr or more Minimum operating liquid volume: 20–30L (3) MSS-F03-PM Device dimensions: W915×D651×H1980mm Raw water flow rate: 1.9–3.8㎥/hr Filtration flow rate: 50L/hr or more Minimum operating liquid volume: 20–30L *The filtration flow rate varies depending on the quality of algae and culture solution. *The minimum operating liquid volume refers to the minimum amount of raw liquid required for the device to operate, which varies depending on the tank used. ■Device Components Raw water pump (for seawater)・Frame (with casters)・Piping (PVC)・Valves・Pressure gauge・Flow meter・Thermometer・Control panel ■Device Operating Method Manual operation 【Additional Options】 ■Raw water tank (concentration tank) ■Filtration water tank ■Back pressure washing function ■Automatic operation control

Price information

Please contact us from the HP.

Price range

P5

Delivery Time

※Please feel free to contact us from HP.

Applications/Examples of results

■Aquaculture seedling manufacturer in Ehime Prefecture At the customer's site, after processing 20-30 tons/day of Nannochloropsis culture solution for about 24 hours, we achieved a concentration of approximately 900 times with CA membranes and about 600 times with PES membranes. ■Ongoing processing test results with various algae Nannochloropsis, Kitaseros (diatoms), Botryococcus, Chlamydomonas, etc. ■Expansion of the microalgae market Microalgae are in demand in the aquaculture market as feed for bivalves, and there are expectations for applications in the development of health foods and cosmetics from the components contained in algae.

Line up(3)

| Model number | overview |

|---|---|

| MSS-F20-PM | This device has a filtration capacity of over 500L/h. It can be equipped with the FN20 module. |

| MSS-F10-PM | This device has a filtration capacity of over 150L/h. It can be equipped with the F10 module. |

| MSS-F03-PM | This device has a filtration capacity of over 50L/h. It can be equipped with the F03 module. |

catalog(1)

Download All CatalogsCompany information

Daisan Membrane Systems is a manufacturing and sales company for separation membrane modules, established as a joint venture between Daicel Corporation and Central Filter Industry. Leveraging the technology and experience in separation membrane modules from Daicel Corporation, we continue to explore the future of separation membranes across various industrial fields and applications, including our extensive track record in "water supply and drainage," "pharmaceuticals and medical," "chemicals," "food," and "sewage treatment," as well as in recent years, energy-saving systems using membrane-treated water.