Reliability evaluation of power modules and power devices. We offer proposals from the construction of test environments tailored to your power cycle specifications to investigation and analysis!

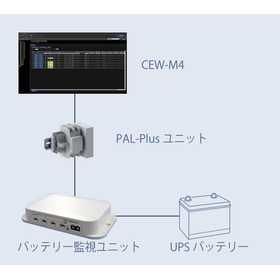

When power semiconductors and power modules are repeatedly turned ON and OFF, the self-heating and cooling of the components and modules cause distortion due to the differences in expansion of the bonding materials, leading to a deterioration in bonding reliability. We offer power cycle testing that takes into account the heating operation due to repeated self-heating and cooling cycles. ■ Components, units, and devices where the adoption of power semiconductors and power modules is progressing: - Traction inverters for electric vehicles (EVs) and hybrid electric vehicles (HEVs) - On-board chargers and DC-DC converters - Motor control, robots, machine tools, elevators - Industrial inverters and uninterruptible power supplies (UPS) - Solar power generation systems and wind power generation systems

Inquire About This Product

basic information

For more details, please download the brochure or contact us.

Price information

For more details, please contact us.

Delivery Time

Applications/Examples of results

- Environmental testing of power MOS FETs and analysis after implementation - Use of a temperature cycle test chamber in environmental testing of power modules, etc.

catalog(11)

Download All Catalogs

News about this product(1)

Company information

Eurofins FQL Co., Ltd. has its origins in the analysis division of Fujitsu Laboratories Ltd. and the quality assurance department of Fujitsu Ltd. It has long engaged in activities aimed at improving product quality, not only in material analysis, reliability evaluation, safety assessment, and failure analysis, but also in supplier quality management and manufacturing plant audits. Additionally, it contributes to solving challenges faced by organizations responsible for quality through the development and educational support of personnel involved in quality, as well as the construction and improvement of quality management, product chemical substance management systems, and software development processes. ■ Reliability Evaluation and Environmental Testing Various reliability evaluations, safety verification of secondary batteries and power supplies, etc., including smoke and fire hazards. Evaluation of special environments such as weather resistance and gas corrosion. ■ Failure Analysis Failure analysis of electronic components and devices, confirmation of characteristics related to materials, and detailed analysis of defects. ■ Support for Building and Improving Quality-Related Systems and Processes To achieve QCD (Quality, Cost, Delivery) goals, we support the improvement of development processes using models such as CMMI and Automotive SPICE. ■ Quality-Related Education Customized educational programs tailored to specific challenges, such as "I want to revitalize the organization," "I want to cultivate a quality mindset," and "I want to provide quality education for new employees."

![[Failure Analysis Case] Introduction to Lock-In Heat Generation Analysis Method](https://image.mono.ipros.com/public/catalog/image/01/dbe/610075/IPROS75070223538131318883.jpeg?w=120&h=170)

![If it's oil | Generator engine oil [JPG ZERO] Generator](https://image.mono.ipros.com/public/product/image/eb1/2000852308/IPROS30478244085557726193.png?w=280&h=280)