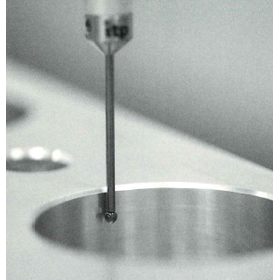

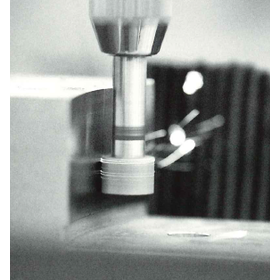

High precision × capable of diverse processing and various materials! High precision jig grinding processing.

Grinding by specialized technicians centered around Moore G18/G48! We can handle everything from material procurement to rough processing and finishing processes.

Our company possesses machining technology at the micron level (1/1,000 mm) and responds quickly to requests for "high-precision jig grinding" from the start of production at our two bases in Yokohama and Niigata. We are well-suited for precision hole machining and precision grinding of hard materials, such as motor cores related to the automotive industry, where recent demands for dimensional accuracy and durability are stringent. We accept various processing services, including jig grinding, parts machining in a consistent production process, and the manufacturing of ultra-high-precision molds. Please feel free to contact us for any inquiries. 【Features】 ■ Grinding by specialized technicians centered on Moore G18/G48 ■ High-precision machining at 1/1,000 mm ■ Capable of diverse processing and various materials ■ Able to handle everything from material procurement to rough and finishing processes *For more details, please download the PDF or feel free to contact us.

Inquire About This Product

basic information

【Specifications】 ■ Hole diameter: Accuracy guaranteed from φ0.8 to φ300, capable of processing from φ0.4 to φ600 according to machine specifications ■ Work size: Maximum 600mm × 1200mm × Z500mm (weight up to 1 ton) ■ Tolerance: H6/H7, roundness from 0.001mm and above ■ Equipment: 19 Moore jig grinding machines in total ■ Ancillary equipment: 3D measuring machine, roughness measuring machine, block gauges, pin gauges ■ Compatible materials: SKD, STAVAX, super steel, SUS, aluminum, copper, etc. (please consult us) ■ Process steps: Consultation → Meeting → Order → Processing → Inspection → Delivery *For more details, please download the PDF or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

【Applications】 ■ High-precision hole machining ■ Machining of positioning reference holes ■ Alternative to finishing processes (post holes for press molds, bushing holes, knock pin holes, corner pockets for mold inserts, round holes, square holes, and irregularly shaped punches and dies with micron-order clearance) *For more details, please download the PDF or feel free to contact us.

catalog(1)

Download All CatalogsCompany information

We are a company that sells "jig grinding" technology. Since our founding in 1968, we have continued to strive to be one-of-a-kind with our expertise in "jig grinding" as a technical group. We handle precision machine parts and mold jig grinding, constantly making efforts to enhance our technical capabilities and reduce our return rate to as close to "zero" as possible. This has earned us the trust of many customers, and we receive work from over 200 major automotive and home appliance manufacturers nationwide. Our commitment to quality work starts with "good equipment." We actively introduce jig grinding machines from Moore Tool Company, a long-established American manufacturer known for its world-class performance, and together with the skills of our operators, we challenge ourselves to deliver highly reliable work that exceeds the limits of jig grinding.

![[Introduction to Processing Technology] Jig Grinding Processing, Thermic Co., Ltd.](https://image.mono.ipros.com/public/product/image/258/2000332956/IPROS7103336154208286402.JPG?w=280&h=280)

![[Processing Reference Example] Casing Screw Machining](https://image.mono.ipros.com/public/product/image/2088546/IPROS16021466541096188662.png?w=280&h=280)