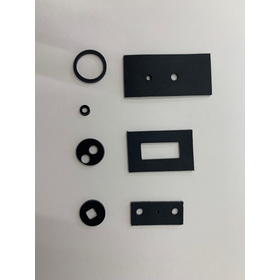

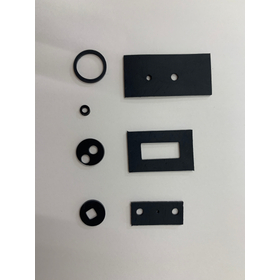

Packings specialized for high-temperature environments, enhancing reliability.

In the aerospace industry, the reliability of components under extreme temperature conditions is extremely important. In particular, in areas exposed to high temperatures, such as engines and the interior of the aircraft, the performance of seals affects safety. Seals with low heat resistance can lead to degradation or damage, potentially resulting in serious accidents. Our ultra-heat-resistant grade seals are specifically designed for use in high-temperature environments and meet the stringent demands of the aerospace sector. [Application Scenarios] - Engine components - Seals in the aircraft interior - Piping in high-temperature environments [Benefits of Implementation] - Increased lifespan of components due to high heat resistance - Improved safety - Reduced maintenance costs

Inquire About This Product

basic information

【Features】 - Made with ultra heat-resistant grade silicone rubber - Heat resistance temperature: typically 250°C to 280°C, withstanding up to 300°C momentarily - RoHS compliant - Thomson type, processed by punching 【Our Strengths】 Aizu Rubber Industry is your go-to for rubber and plastic resin molding. We offer ultra-fast and high-quality service from mold production to product delivery, which cannot be matched elsewhere. As a research and development, design, manufacturing, and sales proposal company, we have a system in place to timely propose optimal products tailored to our customers' needs, along with logistical support. For custom-made products outside standard specifications, we can provide full customization from design to manufacturing and shipping through collaboration with our own factory and partner manufacturers.

Price range

Delivery Time

Applications/Examples of results

Packing for high-temperature areas Furnace packing for factories It is also used in high-temperature parts of electronic devices.

Company information

Aizu Rubber Industry is a research and development, design manufacturing, and proposal sales company. Since our establishment in 1970, we have consistently responded to the needs of the dental and general medical device markets, as well as industrial rubber products, from prototype to mass production, including plastic and metal products. As a proposal-oriented trading company, we offer a wide range of products and flexible suggestions, from parts and components to machinery and equipment. We have established a system in collaboration with numerous partner manufacturers to timely propose optimal products that meet our customers' needs, along with logistical support. Particularly for custom-made products that fall outside standard specifications, we can provide full customization from design to manufacturing and shipping through collaboration with our own factory and partner manufacturers. Please let us know your inquiry, and we will provide you with proposals and estimates. We are also available for consultations and meetings in person, so please feel free to contact us.

![Burr Removal Machine "Baritor IV" [Eligible Model for Small and Medium Enterprises Productivity Investment Subsidy]](https://image.mono.ipros.com/public/product/image/7e6/2000308307/IPROS7133207276557527838.png?w=280&h=280)

![Burr Removal Machine "Triple Baritol" [Eligible for Small and Medium Enterprise Labor-Saving Investment Subsidy]](https://image.mono.ipros.com/public/product/image/fbb/2000308526/IPROS10846500360243567721.png?w=280&h=280)

![The first step in automating factories and warehouses starts with floor leveling [with case studies included].](https://image.mono.ipros.com/public/product/image/8e6/2001522448/IPROS11175175298099575604.png?w=280&h=280)