Please leave the 'Ishikawa-style stirring and grinding machine' for 'stirring', 'crushing', 'mixing', and 'kneading' to Ishikawa Factory Co., Ltd.

【Features】 - Maintains the characteristics of the Ishikawa-type mixing and grinding machine, achieving higher grinding performance by forcibly rotating the pestle with a motor. - Being a tabletop model, it is suitable for experiments in research and development, and can also be used within a draft chamber. - Offers a selection of materials for the bowl and pestle, including agate, alumina, and tungsten carbide, allowing customers to choose materials according to their needs. - Comes standard with a protective cover to suppress dust dispersion. - Additionally equipped with an interlock mechanism that stops the pestle rotation when the cover is opened, providing a safety feature. 【Suitable Use Cases】 - Used as an experimental machine for research and development, suitable for grinding (milling) and dispersing small quantities of the following materials: - Ceramics such as titanium (Ti), zirconia (ZrO2), silica (silicon dioxide SiO2), alumina (Al2O3), α-tricalcium phosphate ceramic, silicon carbide (SiC), aluminum nitride (AlN), silicon nitride (Si3N4), etc. - Processing of rare earth/high-performance metals such as carbon, iridium, bismuth, tellurium (Bi2Te3), lead, tin, niobium, tungsten, molybdenum, antimony, platinum, gold, silver, copper, etc.

Inquire About This Product

basic information

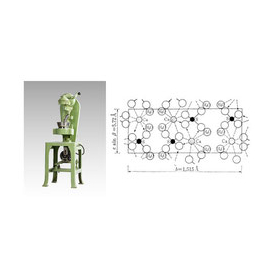

**Features of the Ishikawa Type Stirring and Crushing Machine** The following features are available: (1) Uniform and consistent stirring and crushing treatment within the bowl due to unique design (2) Simultaneous stirring and crushing processing is possible (3) High driving torque allows for processing of high-viscosity materials (4) Lower processing energy compared to ball mills, enabling "mild processing" **Basic Specifications of the Product** - Bowl types: Agate, Alumina, Tungsten Carbide - Bowl inner diameter: Agate: 120mm, Alumina: 120mm, Tungsten Carbide: 140mm - Bowl depth: Agate: 30mm, Alumina: 30mm, Tungsten Carbide: 63mm - Processing volume: 0.05L - Device width: 410mm - Device depth: 490mm - Device height: 1180mm - Power supply: 100V, 0.2kW **Introduction to the Testing Laboratory** You can use the experimental machine free of charge for functional and performance evaluation of the Ishikawa type stirring and crushing machine. Additionally, our staff, who are well-versed in stirring and crushing processes, will support your experiments according to your needs. Furthermore, we will propose the optimal selection of the Ishikawa type stirring and crushing machine and the stirring and crushing treatment for your processing needs. Please feel free to utilize this when considering your options.

Price information

-

Delivery Time

Applications/Examples of results

■This machine is primarily designed for the preparation of analysis samples and the grinding of small amounts of hard materials. ●It is widely used for the kneading and mixing of piezoelectric sensors, gas sensors, MEMS sensors, thermal conversion elements, porous ceramics, LTCC multilayer substrates, 3D printer pastes, dental materials, artificial bone, and materials for artificial joints. ●In universities and corporate research and development departments, it is also used for the stirring and grinding of the following materials: - Electronic component materials (sizing of ceramic particles) - Conductive inks, conductive adhesives (sizing of conductive particles and dispersion/mixing of adhesives) - IR transparent inks (dispersion/mixing) - Insulating materials, sealing materials (sizing of insulating materials and dispersion/mixing of sealing materials) - 3D printer materials (dispersion/mixing) - Synthesis processing of hydrogen storage materials - Pigments, glazes (sizing of pigments, etc.) - Metal (gold, silver, copper) pastes - Glass pastes - Carbon pastes - Lithium battery materials, electrode materials for all-solid-state batteries - Dispersion of carbon nanotubes - Abrasive stones, abrasive grains, polishing agents - Brake shoes - Pharmaceuticals, ointments (dispersion/mixing) - Chemicals and cosmetics (sizing and dispersion/mixing of metal nanoparticles) - Chemical and fiber materials - Research and development equipment and devices (automatic mortar and pestle function)

Detailed information

-

AGA type - The rotation speed of the pestle can be changed. - The pestle rotates while orbiting, and forced rotation by the motor improves the grinding performance. - By rotating the lever, the bowl descends, making it easy to remove the materials.

catalog(5)

Download All Catalogs

![[Use Case] Example of the use of composite electrodes for lithium-ion batteries: Introduction to the published technical monograph.](https://image.mono.ipros.com/public/catalog/image/01/1a3/739990/IPROS52434389648099151179.png?w=120&h=170)

News about this product(3)

Company information

Our company is a specialized manufacturer of automatic mortar and pestle machines. The features of the automatic mortar and pestle (Ishikawa-style stirring and grinding machine) include the ability to simultaneously perform stirring, grinding, mixing, and kneading using unique technology. It has the following basic capabilities: 1. Uniform and precise mixing is possible - Allows for uniform mixing while controlling particle size. 2. Easy uniformity and control of particle size - Can achieve uniform particle size while finely grinding. 3. Prevents excessive deterioration of materials - Due to low mechanical stress (mild processing energy), it can process while suppressing over-grinding and chemical changes. - High-energy processing (such as ball mills) can cause reaction changes due to heat generation, but temperature management is easier with the automatic mortar and pestle. 4. Suitable for small-scale prototyping and experiments - Ball mills and planetary mixers require large amounts of raw materials, but the automatic mortar and pestle can prototype with a minimum of 0.5g. - Easily adaptable for process scale-up (easy application from small to large scale). 5. Capable of processing slurries, pastes, and high-viscosity materials - The motor torque for the pestle rotation is high, allowing for processing of high-viscosity materials.

![[Case Study] Introduction of the paper using AGA "Mechanochemical Dehydration of Hydrate Crystals"](https://image.mono.ipros.com/public/catalog/image/01/52d/739989/IPROS29414558935298517792.jpeg?w=120&h=170)

![[Comprehensive Catalog] Ishikawa-style Automatic Mortar and Pestle, Ishikawa Factory Co., Ltd.](https://image.mono.ipros.com/public/catalog/image/01/007/759980/IPROS7614596388894315027.jpeg?w=120&h=170)

![[Heating/Cooling Type] 24REB Automatic Mortar for Stirring, Mixing, Crushing, and Kneading](https://image.mono.ipros.com/public/product/image/2bb/2001504801/IPROS25542357994764581749.png?w=280&h=280)