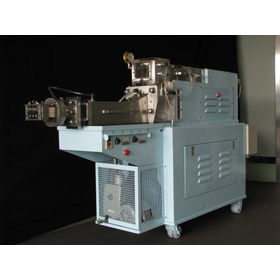

With inverter control, you can select high to low rotation speeds for operation! By combining powder materials with a binder and water, you can mix the raw materials evenly in a short time.

Structure The raw material mixing case is drum-shaped and has a central rotating axis. It can precisely blend the base of extruded materials by spraying water, additives, etc., from the top while controlling a special rotating blade via an inverter. Features ● Mixing time and spraying time can be automatically controlled by a timer ● The mixing case adopts a water-cooled jacket structure to prevent heat generation of the raw materials (except for small machines) ● The mixing case can be detachable to accommodate various types and wear resistance (only for small machines)

Inquire About This Product

basic information

For more details, please refer to our official website.

Price information

Please contact our Kyushu factory directly. TEL: 0954-66-2872 Email: kyushu@universe-kk.co.jp

Delivery Time

※Please feel free to contact us.

Applications/Examples of results

It is a mixer for mixing powder materials and binders in the process before feeding materials into the molding machine.

catalog(1)

Download All CatalogsCompany information

Our company specializes in extrusion molding. For over 50 years since our founding, we have continued to pursue advanced technology in vacuum kneading extrusion molding. We ask both customers introducing equipment and those developing extrusion molded products to start with extrusion molding tests. In the initial extrusion molding test for evaluation, we will hold your materials and use our vacuum kneading extrusion molding machine to check if molding is possible. After that, we ask you to evaluate the molded product and consider whether to continue using our services. We primarily focus on the design, development, manufacturing, and sales of custom-made vacuum kneading extrusion molding machines tailored to each customer's materials. Additionally, customers developing extrusion molded products can utilize our paid extrusion molding tests as many times as needed. While our expertise lies in ceramic-based materials, we also have a track record with carbon, metals, and food products. In extrusion molding, we will leverage our years of experience to provide satisfactory services and products that can fully reflect our customers' needs.

![[Technical Data Presentation in Progress!] O-Ring Reaction Force Measurement Test](https://image.mono.ipros.com/public/product/image/1b7/2001007916/IPROS65438292025686709186.png?w=280&h=280)

![Deburring Machine "Twin Baritor" [Eligible for Small and Medium Enterprise Productivity Investment Subsidy]](https://image.mono.ipros.com/public/product/image/6d3/2000308654/IPROS16685940644635288329.png?w=280&h=280)