By extruding the molded body in the vertical direction according to gravity, dimensional accuracy is improved. Recommended for the production of large molded bodies!

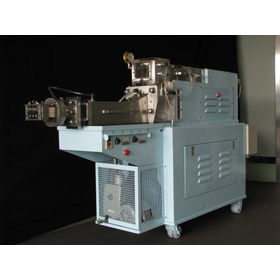

In the manufacturing of ceramic molded bodies, horizontal extrusion molding machines are widely used; however, there is a drawback that as the products become larger, the molded bodies are prone to deformation when extruded horizontally. As a solution, our company has developed a vertical extrusion molding machine, successfully achieving continuous molding of molded bodies with good dimensional accuracy by extruding them vertically under the influence of gravity. [Patent] Registration number: No. 5578696, Name: Continuous Molding Device for Ceramic Molded Bodies - By extruding the molded bodies in accordance with gravity, dimensional accuracy is improved. This is recommended for the production of large molded bodies. - It is a vertical extrusion machine integrated with a two-stage vacuum kneading machine as the supply unit and a vertical single-axis feeding screw. - For molded bodies with a diameter of 180 mm or more, the vertical extrusion machine is recommended.

Inquire About This Product

basic information

We are conducting extrusion molding tests at any time using our company's vertical molding machines. If you bring or send your materials and molds, our staff will perform test molding and sample collection. This can be widely used for product development and performance testing. We will customize the machines as a testing machine or for mass production according to the capabilities desired by the customer.

Price information

Please contact our Kyushu factory directly. TEL: 0954-66-2872 Email: kyushu@universe-kk.co.jp

Delivery Time

※Please feel free to contact us.

Applications/Examples of results

Molding materials: ceramic, activated carbon, metal, food, etc. Molding shapes: honeycomb, sheet, round bar, pipe, filter, etc. Applications of molded products: electronic devices, VOC countermeasures, deodorization, air purification, etc.

Line up(2)

| Model number | overview |

|---|---|

| VT-300 | ▼Processing capacity: Maximum 250kg/H ▼Device power/vacuum exhaust volume: 15x15x5.5kw ▼Material cylinder diameter: φ300mm ▼Machine dimensions: L4,700xW1,200xH3,800mm ▼Machine weight: 10,000kg ※The numbers listed are for reference. |

| VT-400 | ▼Processing capacity: Maximum 400kg/H ▼Device power/vacuum exhaust volume: 30x22x7.5kw ▼Material cylinder diameter: φ300mm ▼Machine dimensions: L7,500xW1,200xH4,400mm ▼Machine weight: 22,000kg ※The numbers listed are for reference. |

catalog(1)

Download All CatalogsCompany information

Our company specializes in extrusion molding. For over 50 years since our founding, we have continued to pursue advanced technology in vacuum kneading extrusion molding. We ask both customers introducing equipment and those developing extrusion molded products to start with extrusion molding tests. In the initial extrusion molding test for evaluation, we will hold your materials and use our vacuum kneading extrusion molding machine to check if molding is possible. After that, we ask you to evaluate the molded product and consider whether to continue using our services. We primarily focus on the design, development, manufacturing, and sales of custom-made vacuum kneading extrusion molding machines tailored to each customer's materials. Additionally, customers developing extrusion molded products can utilize our paid extrusion molding tests as many times as needed. While our expertise lies in ceramic-based materials, we also have a track record with carbon, metals, and food products. In extrusion molding, we will leverage our years of experience to provide satisfactory services and products that can fully reflect our customers' needs.

![[Mandatory Compliance] Truck Backup Sonar | Proven track record of 6,000 units installed](https://image.mono.ipros.com/public/product/image/2072982/IPROS1365987416322734488.png?w=280&h=280)