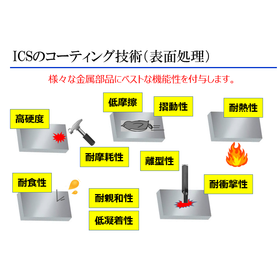

We can create high-performance coatings on molds, cutting tools, machine parts, and engine components, resulting in long-lasting, high-value-added products.

Our standard DLC "Hi-coatδ" is a film that has high adhesion and is difficult to peel off. It improves low friction, wear resistance, and corrosion resistance. 【Features】 - Capable of mass production with large machinery. - Provides optimal films according to application. - Develops and supplies high-performance films for motorsports and other applications. - Equipped with various measuring devices for practical property verification. - Quality assurance system based on ISO9001. For more details, please download the PDF or feel free to contact us.

Inquire About This Product

basic information

DLC (Diamond-like Carbon) was first synthesized in 1971 by Aisenberg and Chabot using ion beams. Currently, the diverse properties of DLC are attracting attention, and along with its various film deposition methods, the range of applications is continuously expanding. ICS is depositing DLC by combining magnetron sputtering and PACVD. Utilizing features such as low friction, wear resistance, high corrosion resistance, and low adhesion, it has been well received in applications including automotive parts, machine components, cutting tools, and mold parts. At ICS, Hi-Coatδ (DLC2230) is offered for general applications, Hi-Coatδ+ (DLC6230) for high surface pressure applications, and GSI (DLC003) for non-lubricated low friction applications. On the other hand, development of custom-made DLC films with optimal properties for specific applications is also being conducted.

Price information

-

Delivery Time

Applications/Examples of results

Please contact us.

catalog(3)

Download All CatalogsNews about this product(1)

Company information

I.C.S. provides optimal functionality for metal components in various fields such as automotive, aerospace, electrical equipment, infrastructure, and medical as a "comprehensive heat treatment manufacturer." We work together with our customers from development to mass production through meetings, collection, cleaning, processing, inspection, and delivery, assisting in achieving results. ■ We have over 700 business partners annually! > We can accommodate short delivery times! > Prototyping is possible from just one piece! > We can also handle mass production of large lots! Additionally, we have obtained various certifications, including JISQ9100 (Aerospace Quality Management System) and ISO14001 (Environmental Management System), ensuring strict quality control and environmentally friendly business practices for the safe and secure supply of products. The technological strength of I.C.S. is born from trust. Since our founding nearly 50 years ago, we have developed alongside our customers. Please feel free to consult us about any characteristics or functions that may not meet your current needs. We also offer online consultations. Our company has gained trust not only from the six prefectures of Kanto but also from partners in Tohoku, Chubu, and Kinki regions across the country.

![DLC Coating [Low Friction and High Adhesion]](https://image.mono.ipros.com/public/catalog/image/01/494/243942/IPROS18551084632819165171.jpeg?w=120&h=170)

![[Case Study Collection] ICS Co., Ltd.](https://image.mono.ipros.com/public/catalog/image/01/876/602878/IPROS91186107236113569293.jpeg?w=120&h=170)

![[Case Study] Coating for Gear Processing Tools](https://image.mono.ipros.com/public/product/image/904/2000648051/IPROS38683976880003798395.png?w=280&h=280)

![[Comprehensive Catalog] High-performance pharmaceuticals packed with 110 years of history and technology.](https://image.mono.ipros.com/public/product/image/7fc/2000153777/IPROS51294870868527324567.jpeg?w=280&h=280)