Explosive Bonding Clad: Enables the Joining of Dissimilar Metals That Cannot Be Welded!

We offer structural dissimilar material joints that enable strong bonding between lightweight metals such as aluminum, magnesium, titanium, and steel materials!

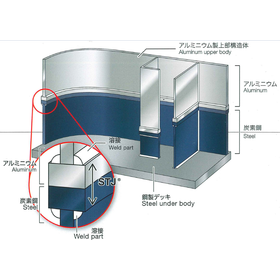

Asahi Kasei Corporation has an explosive welding technology that utilizes the instantaneous high energy generated when explosives detonate to metallurgically join dissimilar metals at room temperature. This product significantly contributes to the weight reduction of vehicles, ships, molds, and more. ■ STJ(R) "Structural Transition Joint" STJ(R) is a compact and highly durable structural joint that enables the welded integration of aluminum alloy structures with carbon steel or stainless steel components. ■ Flame-retardant Magnesium Alloy Joint A structural joint made of flame-retardant magnesium alloy and aluminum alloy or stainless steel. *For more details, please refer to the PDF document or feel free to contact us.

- Company:旭化成 機能品営業部 金属加工グループ

- Price:Other