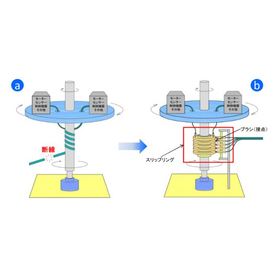

Low noise, low rotational torque slip ring with planetary motion mechanism.

Introducing slip rings that can be used in hoop plating devices and electrolytic degreasing devices!

We would like to introduce our uniquely designed planetary motion slip ring (rotary connector) developed in-house. The "50A Slip Ring" features low contact resistance and is smaller and has a longer lifespan than slip rings using carbon brushes. We also offer a "High-Frequency High-Current Slip Ring" that can be directly mounted to a through hole, and a "Signal Slip Ring" that allows for noise-free transmission of small signals. Please feel free to contact us for inquiries. 【Applications (partial)】 ■ Semiconductor manufacturing equipment ■ Rotary welding machines ■ Hoop plating equipment ■ High-frequency power supply applications (related to semiconductor manufacturing equipment) ■ Large printers ■ Electrolytic degreasing equipment *For more details, please refer to the PDF document or feel free to contact us.

- Company:ヒサワ技研

- Price:Other

![[Case Studies of Problem Solving] Custom-made products and high-performance items that require considerable effort in manufacturing.](https://image.mono.ipros.com/public/product/image/0ae/2000575716/IPROS68575251861475179600.jpeg?w=280&h=280)

![[New Release] Combining communication and power 3A into one! High-speed compact slip ring!](https://image.mono.ipros.com/public/product/image/acb/2000788757/IPROS13004332996840687244.jpeg?w=280&h=280)

![Automobile [Brake Rotor Temperature Measurement] Simple Drip-Proof Wheel Jig](https://image.mono.ipros.com/public/product/image/e0e/2000122723/IPROS5613112035503194036.jpg?w=280&h=280)

![[Turbine Stress/Strain Measurement] Slip Ring SR20M/GEVL](https://image.mono.ipros.com/public/product/image/240/2000135057/IPROS5671539034992694189.jpg?w=280&h=280)