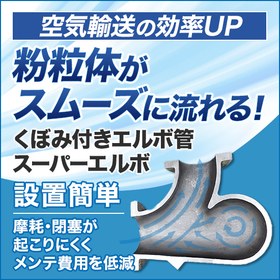

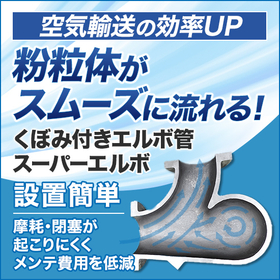

Reduce wear and blockage troubles, and lower maintenance costs. Easily installable without changing the existing system. *We are currently providing delivery performance data for air transport raw materials!

The "Super Elbow" is a piping component that can be installed at the corners of pipes to prevent issues such as wear, blockage, and particle deformation in air transport.

By allowing air and powder particles to gently rotate within the recess created between the inlet and outlet, it can suppress collisions of transported materials with the pipe walls, thereby extending the lifespan of the piping. It has a small installation size, making it possible to install in a compact space.

Our company also offers "Tubular Conveyors" that can transport powders and granules in various directions, including horizontal, vertical, and inclined.

【Features of the Super Elbow】

■ Suppresses troubles such as "wear," "blockage," and "shape change"

■ Reduces the frequency of dust dispersion during pipe damage

■ Active in a wide range of industries including cement, steel, mining, chemicals, and food

■ Selected for the "Kitakyushu Eco Premium" in fiscal year 2020

*For more details, please refer to the PDF document or feel free to contact us.

- Company:山本工作所

- Price:Other

![[KSE-LO] Explosion-proof street elbow (with O-ring)](https://image.mono.ipros.com/public/product/image/b5d/2000962858/IPROS48445034339948773096.jpeg?w=280&h=280)