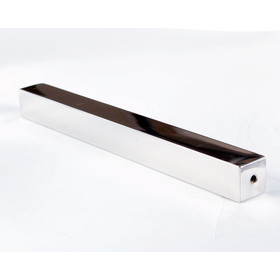

Magnetic separator for foreign matter removal, magnet bar φ25×400 1,2T

Usable in all factories. With high magnetic strength, it adsorbs and removes fine iron powder and metal fragments (magnetic materials).

Magnet bars (magnet rods) are used to remove fine iron powder that may be mixed in rice, tea, meat, seasonings, beverages, food, pellets, and industrial materials. They are designed with a hygienic sanitary specification, making them suitable for food processing, and can be washed with water to be used as a magnetic filter. Equipped with a maximum surface magnetic flux density of 1,200 mT, the high-strength magnet with a diameter of 25 mm can attract and capture fine iron powder, and the exterior is made of stainless steel. Custom manufacturing is possible in lengths measured in millimeters.

- Company:サンギョウサプライ

- Price:Other