1~25 item / All 25 items

Displayed results

Filter by category

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Contact this company

Contact Us Online1~25 item / All 25 items

Filter by category

In the game controller industry, the miniaturization and high functionality of products require precision in internal structures. In particular, adjusting the gaps between components that affect operability and durability is crucial. Low precision in spacers can lead to decreased operability and potential malfunctions. Spacers made through photo-etching processing achieve precise manufacturing without burrs, contributing to the improvement of controller quality. 【Application Scenes】 - Internal structure of game controllers - Adjustment of button and stick placement - Gap adjustment between the circuit board and housing 【Effects of Implementation】 - Improved operability of controllers - Enhanced durability of products - Increased design flexibility

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the watch industry, there is a trend towards miniaturization and high precision of products, which requires the fine processing of components. Particularly in precision parts such as movements, the accuracy of dimensions and the absence of burrs are critical factors that influence product quality. Spacers produced through photo-etching processing address these challenges and provide high-quality products. 【Usage Scenarios】 - Spacers inside movements - Gap adjustment between cases and components - Assembly of precision instruments 【Benefits of Implementation】 - Achievement of high-precision components - Burr-free finishing - Cost-effective manufacturing

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the measurement instrument industry, precise dimensions and stable quality are required in calibration work. Especially in situations where fine adjustments are necessary, high-precision spacers are essential. If the accuracy of the spacers is low, errors can occur in the calibration results, potentially compromising the reliability of the measurement instruments. Our company provides precision spacers without burrs through photo-etching processing, contributing to the improvement of calibration accuracy for measurement instruments. 【Usage Scenarios】 - Calibration work for measurement instruments - Assembly of precision equipment - Adjustment of gaps between parts 【Benefits of Implementation】 - Achievement of high-precision calibration work - Improvement of measurement instrument reliability - Enhancement of work efficiency

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the energy storage industry, miniaturization and high performance of devices are progressing, making internal space management crucial. In particular, spacers that accurately maintain the distance between electrodes significantly affect the efficiency and safety of energy storage devices. There is a demand for precise spacers without burrs or bridges, and material selection and cost are also important challenges. Our photochemical etching process addresses these challenges and contributes to the performance enhancement of energy storage devices. 【Application Scenarios】 - Lithium-ion batteries - Capacitors - Fuel cells 【Benefits of Implementation】 - Improved device performance - Enhanced product reliability - Cost reduction

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the optical lens industry, precise positional adjustment between lenses is a crucial factor that affects optical performance. Especially in high-precision optical systems, the accuracy of spacers significantly impacts image clarity and distortion levels. Spacers with burrs or distortions can hinder light transmission and potentially lead to performance degradation. Our photo-etching processed spacers address these challenges. 【Application Scenarios】 - Adjustment of gaps between lenses - Positioning of optical components - Precise optical axis alignment 【Benefits of Implementation】 - Achievement of high-precision optical performance - Improvement in product quality - Enhancement of yield rates

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the electronics industry, as the miniaturization and high density of circuit boards progress, the precision of spacers affects the reliability of products. In particular, the accurate dimensions and quality of spacers are crucial for ensuring clearance between components and for thermal management. If there are burrs or distortions, it can hinder the assembly of the circuit board and potentially lead to a decline in product performance. Our spacers, produced through photo-etching processing, address these challenges. 【Application Scenarios】 - Spacers for electronic device circuit boards - Components for precision instruments - Addressing challenges related to various sizes, materials, and thicknesses 【Benefits of Implementation】 - Providing precise spacers without burrs - Responding to needs for small lots and various types - Enabling production at low costs

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the robotics industry, precise components for movable parts are required. Especially in areas where repetitive motion and high accuracy are demanded, the quality of the parts significantly affects the overall performance of the robot. If there are burrs or distortions, it can lead to operational failures or premature wear. Our spacers made through photo-etching processing address these challenges. 【Application Scenarios】 - Joints of robotic arms - Fixing sensors and cameras - Areas requiring precise positional adjustments 【Benefits of Implementation】 - Achieving smooth operation of movable parts - Improved durability and reliability - Contributing to cost reduction

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the automotive industry, sensors require precise positioning and stable performance. Particularly in environments exposed to vibrations and temperature changes, the accuracy of spacers affects the reliability of the sensors. Any burrs or distortions can lead to sensor malfunctions or performance degradation. Our photo-etched spacers address these challenges. 【Application Scenarios】 - In-vehicle sensors - Autonomous driving systems - Safety driving assistance systems 【Benefits of Implementation】 - Improved sensor accuracy - Enhanced product reliability - Cost reduction

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the medical device industry, the miniaturization and precision of products are advancing, and the quality of components is being emphasized. In particular, for precision parts such as spacers, accurate processing without burrs or distortions is required. Improper processing can lead to a decline in equipment performance or failure. Our photo-etching processing achieves precise machining without burrs, contributing to the improvement of medical device quality. 【Application Scenarios】 - Assembly of medical devices - Fixing precision parts - Adjusting fine gaps 【Effects of Implementation】 - Provision of precision parts without burrs - Support for small lots and diverse varieties - Improvement of medical device quality

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the semiconductor industry, masks are a crucial element that affects the precision of microfabrication. The quality of the mask is directly linked to the performance of semiconductor devices, requiring high precision and reliability. If the accuracy of the spacers is low, it can lead to misalignment and distortion of the mask, potentially resulting in decreased yield. Our company provides precision spacers without burrs using photolithography processing technology, contributing to solving challenges in mask manufacturing. 【Usage Scenarios】 - Semiconductor mask manufacturing - Microfabrication processes - Situations requiring high-precision spacers 【Benefits of Implementation】 - Improvement in mask quality - Enhancement of yield - Reduction in manufacturing costs

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

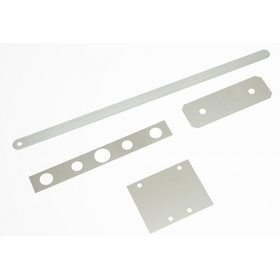

We would like to introduce a case of photo-etching processing for a device called a "spacer" that secures space by being inserted in between. We received a consultation from a client who desired a flexible development, and technically requested a solution without burrs and at a low cost. The challenge in the process was carefully selecting various sizes of materials to manufacture at a low cost. We are also considering costs for essential original plates needed for etching through shared use and other methods. [Case Overview] ■ Requests - Processing method capable of low-cost etching - No burrs, non-bridged, small lots - Various sizes, with challenges regarding materials and thickness ■ Achievements - Conducting discussions and processing within the process to handle thin plate thicknesses without bridges - Working quickly to prevent rust depending on the material *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "film mask" is a mask produced through exposure, development, and fixing, similar to photographic negative film. It uses PET film as the base material, making the film mask lightweight and flexible compared to glass masks, which makes it easy to handle. Additionally, it offers excellent cost performance and can achieve short delivery times (same-day service available). 【Features】 ■ Lightweight and flexible, making it easy to handle ■ Space-saving for storage ■ Short delivery times ■ Low cost *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company specializes in "etching processing," which enables precise metal machining without warping, bending, or distortion. Orders can be placed from just one piece, catering to the needs of prototypes and small lots of various types. We excel in short delivery times, with the possibility of same-day delivery at the earliest. We are flexible in responding to requests for etching processing based on photos and illustrations, bridge-less processing, machining of thin plates with a thickness of 5μm, and secondary processing such as bending and plating. Please feel free to consult us for manufacturing parts for equipment, automobiles, and robots. 【Examples of Processing】 ■ Vapor deposition masks ■ Leaf springs ■ Spacers ■ Wrapping carriers ■ Decorative emblems ■ Gobo plates for projectors, etc. *For more details, please refer to our materials. Feel free to contact us as well.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce a case where we created a film mask from a hand-drawn rough sketch for a customer in the photography and gravure industry. The customer requested to produce exposure film using photographic methods, but since they did not have CAD or similar tools, they provided a hand-drawn sketch for us to work from. As it was a hand-drawn sketch, we encountered inconsistencies and unclear points as we progressed. During the data conversion phase, issues such as lack of information and inconsistencies arose. We were able to complete the data conversion by confirming these issues with the customer and resolving them as they came up. [Case Summary] ■ Challenge: The customer was looking for a vendor to produce a film mask. ■ Result: - Reviewed the created data and made modifications to reduce the number of objects and coordinate points. - Confirmed and resolved issues such as lack of information and inconsistencies with the customer throughout the data conversion process. *For more details, please refer to the related links or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company specializes in quick delivery, and we can provide the shortest possible delivery time for photo etching, even on the same day. We excel in producing a wide variety of small lots, and we can accommodate the production of prototypes and other items starting from just one piece. Since we do not require expensive molds used in processes like press working, we can reduce both the design and manufacturing processes as well as costs. Additionally, one of the features of photo etching is its suitability for processing thin sheets, with a proven track record of working with sheets as thin as 5 microns. If you are struggling to produce the products you envision, please give our technical expertise a try. 【Features】 ■ Fastest possible same-day delivery ■ Support from one piece to medium production ■ Achieve low costs ■ Production without original plates is possible ■ Precise processing without burrs *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We received a request to manufacture the wrapping carrier using photo etching that can accommodate low costs. The technical requirements specified that it should be produced without burrs and without bridges. Additionally, due to the characteristics of the product, it will not be mass-produced but rather produced in small to medium lots, with various sizes, materials, thicknesses, and warping, along with detailed requests. Therefore, we manufactured a prototype of the wrapping carrier. Since the customer requested a short delivery time, we responded with the fastest possible delivery for the prototype as well. Furthermore, we are progressing with the manufacturing while considering the process to enable handling of thin plate thickness without bridges. Depending on the material, it is also important to work quickly to prevent rust, so we are consciously paying attention to warping of the material and working diligently. *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We received an inquiry regarding the processing of leaf springs, so we would like to introduce it. The customer's request was for a processing method that can accommodate low costs, specifically through etching. We can address the issues the customer is facing, including small lot production and quick turnaround for small lot prototypes. The main materials for the products include stainless steel (SUS304 series), pure copper (C1100), phosphor bronze (C5191, C5210, etc.), brass (C2680, C2801, etc.), ribbon steel, and beryllium copper. At our company, we primarily produce flat plates through etching, but if there are specific requests, we can also accommodate bending processing by collaborating with precision sheet metal companies. *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Higashinari Ward Living and Working Together Town Development Discussion Group," "Higashinari Ward Office," and "Amagasaki Shinkin Bank / Imazato Branch" members, along with elementary school students and their parents living in Higashinari Ward, visited our company for the "12th Our Town Factory Tour." After touring various departments, they challenged themselves to create designs for photo frame etching. The elementary school students were invited to draw their favorite illustrations and texts on a 25cm square design. Later, the design was scanned to create a film master, and a unique, memorable photo frame was completed through the etching process. All participants, including local elementary school students and their parents, were very pleased, and we are happy to have contributed, even just a little, to the community. *For more details, please refer to the PDF document or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We created an original gobo plate using photo etching. A gobo is a plate that projects a design when light passes through it. We accommodate quick turnaround for prototypes and small lots, and the production of glass gobos is handled by partner factories. Additionally, we are considering and processing to handle thin plate thickness within the process. Depending on the material, we pay attention to issues like warping and strive to work quickly. 【Case Details】 ■Industry: Lighting (Projectors) ■Achievements - Created original gobo plates using photo etching - Accommodated quick turnaround for prototypes and small lots - Production of glass gobos is handled by partner factories *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We received an inquiry regarding the creation of vapor deposition masks, and I would like to introduce it. There are projects that are trying for the first time in research institutions and prototype considerations, and they are experimenting with the characteristics of metal masks. Technically, they requested a solution without burrs and at a low cost. Additionally, there was a request based on artwork as there was no existing data. Therefore, we created a vapor deposition mask using etching technology. We are capable of responding to short lead times for prototypes and small lots, and particularly from research institutions, we have realized projects that accommodate a variety of small lots using etching technology. Furthermore, to meet product requirements for vapor deposition, we addressed demands for flatness, magnetism, and heat resistance. *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company is capable of precision photo-etching processing without burrs. In addition to through-hole processing, we can also perform countersinking to any depth, eliminating the need for expensive mold costs. We can accommodate everything from prototypes to medium-scale production. Additionally, our "ultra-high precision photo masks" are lightweight and flexible, making them easy to handle. They require minimal storage space and have short lead times. We also offer "high precision metal masks," "high precision bump masks," and "original metal squeegees." 【Product Lineup】 ■ Photo-etching processing ■ Ultra-high precision photo masks ・ High precision film masks ・ High precision emulsion masks ・ High precision chrome masks *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our unique laser processing technology allows us to meet various requests for thin plate jigs, including SMT-related metal masks, bump formation masks, and prototype products before press cutting. The stainless steel used for processing is high-precision rolled material, ensuring accurate thickness management. Additionally, our laser processing machine reproduces the true circles required for BGA and CSP shapes according to CAD data, thanks to its high-speed laser head and high-precision linear table drive. 【Options】 ■ Half-etching processing ■ Nymfuron processing (Please consult us for other special specifications) *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our unique additive processing technology supports the fine fields of high-density metal masks. We respond to requests for various types of metal masks, primarily for SMT-related applications, including bump formation masks, COB-compatible masks, fine masks for deposition, and thin plate jigs. Please consult us for special specifications. We will accommodate with short lead times, low costs, and high quality. 【Specifications】 ■ Processing method: Active method ■ Material: Ni (Nickel) Hv370 ■ Taper amount: Within 7% of plate thickness ■ Maximum processing area: 500mm x 600mm ■ Processing plate thickness: 0.03mm to 0.15mm ■ Plate thickness accuracy: Within 10% of plate thickness ■ Shape accuracy: ±10μm *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This product is a metal squeegee that applies metal mask processing technology to a metal blade, featuring special processing that enhances the rolling properties of cream solder and provides adhesion prevention of cream solder through a Nymfron coating. It eliminates the "curling" that occurs with rubber squeegees, allowing for flat printing. Sizes range from 100mm to 350mm in length and 30mm to 50mm in width, and can be processed to specified dimensions. 【S Squeegee Specifications】 ■ Processing Method - S Squeegee: Laser processing + Nymfron coating (optional) - T Squeegee: Laser processing + special processing + Nymfron coating (optional) ■ Set Plate Thickness: t=0.2, t=0.25, t=0.3 ■ Hardness: Hv320–340 ■ Size: Length 100mm to 350mm, Width 30mm to 50mm (can also be processed to specified dimensions) *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company is capable of precision etching with minimal burrs. We can perform not only through-hole processing but also counterboring to any desired depth. There is no need for expensive mold costs, and we can accommodate everything from prototypes to medium-scale production. We can handle a variety of products in small lots ranging from 10μ to 1,500μ. Please feel free to consult us when you need our services. 【Features】 ■ Capable of precision processing with minimal burrs ■ Not only through-hole processing but also counterboring to any desired depth is possible ■ No need for expensive mold costs, accommodating everything from prototypes to medium-scale production *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration