- Publication year : 2024

1~23 item / All 23 items

Displayed results

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Contact this company

Inquiry Form1~23 item / All 23 items

1. The basic elements of a molding machine include the following: a. Material holding device b. Heating device c. Press device for attaching the mold plug d. Vacuum device or pressure device 2. The following are examples of auxiliary devices: a. Material feeding device b. Molded product extraction device c. Devices for operating various parts such as air reduction, hydraulic reduction, and control, etc. d. Trimming and finishing devices for molded products 3. The following processes are required as basic operations: Room temperature material ⇒ Clamping ⇒ Heating and softening ⇒ Molding, cooling ⇒ Exhaust ⇒ Mold release ⇒ Clamping open ⇒ Molded product extraction ⇒ Trimming, finishing (devices that finish simultaneously with molding)

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

<<Wood Materials>> We use well-dried, dense wood with a fine grain. Suitable materials for casting wooden molds include cypress, fir, hinoki, red pine, maple, mahogany, and hickory. 【Features】 - It is inexpensive. Both material and processing costs are low, and production time is short. - The surface condition is poor. The wood grain transfers to the surface of the molded products. - It is suitable for small-scale production. Drying due to heat during molding can cause cracking if molding continues. - The molding cycle is long. Due to poor thermal conductivity, cooling time is extended. - The fabric has poor conductivity, so drag lines do not appear strongly. - There is little deformation after demolding, making it suitable for prototypes.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Quality control is important in plastic containers, and we strive to provide safe and secure products through production and manufacturing management. In the case of food trays, electronic component trays, and pharmaceutical trays, the removal of foreign substances is an indispensable aspect of quality. In June 2021, HACCP was adopted, making standards even stricter. Matsuba Giken Kogyo has introduced the DM-1 model foreign substance removal device manufactured by Wakisaka Engineering Co., Ltd., which is equipped with ion dust removal air that has functions for static elimination and dust removal, effectively removing contaminants such as cuttings, hair, debris, and dust that may be mixed into the products.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The detection of foreign substances in the manufacturing and processing of food, pharmaceuticals, clothing, and chemical raw materials has become an extremely important issue due to the spread of the PL law and HACCP. To detect foreign substances within the inspected products and to prevent foreign matter contamination in advance, we have introduced the NA1-B400-CS model from Nikkadenzoku, which conducts metal detection that poses a high risk to human health. This device detects metals with high sensitivity by causing changes in electromagnetic waves when products containing metal pass through. It features a touch panel for ease of operation, allowing for quick and accurate detection tasks.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce Matsuba Giken Kogyo's "Clean Room." The class of Matsuba Giken Kogyo's clean room ranges from 100 to 100,000 (ISO Class 5 and 6). It is a clean room with a cleanliness level capable of manufacturing pharmaceuticals and food products. The class standards have transitioned to the internationally unified ISO standards; however, the U.S. federal standards classify based on the number of particles larger than 0.5μm contained in one cubic foot (approximately a 30cm square box) of air. Our company has implemented foreign matter removal devices and metal detectors to avoid the risk of foreign matter contamination in products. 【Installed Equipment】 ■ Air Shower ■ Foreign Matter Removal Device ■ Adhesive Roller Application ■ Metal Detector *For more details, please refer to the related links or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is a molding method that combines straight vacuum forming and drape vacuum forming, where a heated and softened thermoplastic resin sheet is stretched with a plug, and then the air between the mold and the sheet is evacuated to closely adhere to the convex shape for molding. 【Features】 1. It allows for thickness adjustment and compensates for the disadvantage of corner areas becoming thin in straight vacuum forming by thickening the corner areas in drape vacuum forming, resulting in less uneven thickness and better molding. 2. The size of the plug, corner radius (corner R), sliding characteristics, temperature, speed, etc., can significantly affect the thickness of the molded product. 3. When molding multiple pieces, there is no influence from adjacent molded products. 4. By bringing the sheet of the flange part to the side wall, efficient molding is possible. 5. Due to the concave molding, the outer surface can be finished precisely. 6. Because of the concave molding, demolding is easy, and some undercuts can be achieved without the need for draft angles.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Alongside straight vacuum forming, this is a basic molding method where a sheet of thermoplastic resin, fixed in a clamp frame, is heated and softened, then pushed up and stretched with a convex shape. After that, the air between the mold and the sheet is expelled to complete the molding. 【Features】 1. Molding is easy. 2. The adjustment of molding conditions is relatively minimal and simple, making molding easy. 3. The inner surface of the molded product contacts the mold, resulting in high precision for inner dimensions. 4. Since scratches and debris from the mold can appear on the inside, careful mold management is necessary for molded products that emphasize the inner surface. 5. Compared to straight vacuum forming, somewhat uniform wall thickness of molded products can be achieved, but the side walls may become thinner. 6. Relatively deep drawing is also possible. 7. In the case of multiple parts, adjacent molds can affect each other, so it is necessary to use a separating grid in the upper clamp frame. 8. As the molded product tightens during cooling, it may become difficult to release. 9. Sufficient draft angles for release must be provided, or if there are vertical walls or slight undercuts, a mechanical knockout device will be necessary. 10. In the case of deep drawing, when pushed up and stretched, the side walls are stretched in one direction, creating directionality in the molded product and reducing lateral strength.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Vacuum forming is a method of processing sheets made of thermoplastic resin (a type of resin that softens and becomes pliable when heated to a suitable temperature and solidifies upon cooling) by heating and softening the sheet, then deforming it under vacuum pressure (removing air through fine holes in the mold to create a vacuum) and cooling it to produce the molded product. The main types of forming methods include: 1. Straight vacuum forming 2. Drape vacuum forming 3. Plug assist vacuum forming 4. Direct heating pressure forming 5. Air slip vacuum forming

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Through deep drawing molding, it is possible to create packages that protect products and look good, even for complex figures. It's a pity that we can't show it from the front, but you might notice it from the side view as well. This is one of the strengths of vacuum molding.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Vacuum forming (vacuum molding) is the most basic molding method. First, a sheet of thermoplastic resin is fixed in a clamp frame and heated to soften it. Next, the mold is raised to expel the air between the sheet and the mold, allowing the molding to take place. In the case of pressure forming, the difference lies in sealing the area around the mold and covering it with a frame to blow in compressed air for pressure molding, but fundamentally, the molding method remains the same. **Features** 1. The molding process is easy due to the few and simple adjustment factors for molding conditions. 2. The outer surface of the molded product contacts the mold, resulting in high dimensional accuracy of the outer shape. 3. Since any scratches or very small debris on the mold will appear on the outer surface, careful mold management is necessary for molded products that emphasize the outer appearance. 4. Deep drawing is not possible; the limit is about 1/2 of the opening of the molded product. 5. There is a lot of uneven thickness, particularly at the corners of the bottom, which tend to be thin. 6. In cases of multiple parts being produced, they do not affect each other when adjacent to each other. Therefore, producing multiple parts is easy. 7. As the molded product cools, it shrinks in the direction of separation from the mold, making demolding easy. 8. The stretching direction is relatively balanced in the biaxial direction, and since there is no directional strength imparted to the molded product, it has relatively high strength.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

At Matsuba Giken, we have long recognized that environmental issues, such as marine plastic waste, are urgent challenges that we, as a container manufacturer, must address. Our company produces various products, including agricultural materials, fruit containers, mixed containers, candy trays, and gift product containers, using plastic sheets (Eco-Starch) made primarily from corn starch. It is said that the increase in "takeout" and "home-cooked" meals during the COVID-19 pandemic has led to a rapid rise in plastic waste. While the frequency of plastic use may temporarily decrease in the post-COVID era, it is undoubtedly expected that the demand for environmentally friendly products, such as biomass plastics, will continue to grow. Our company will continue to explore various sheets and additives (compounds) manufactured and supplied by resin manufacturers, and we will persist in sustainable product development going forward.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is a method of vacuum forming where a sheet of thermoplastic resin, softened by heating, is free-blown, and after pushing up a convex mold, the air between the mold and the sheet is expelled to perform vacuum forming. 【Features】 1. It allows for deeper forming compared to trade vacuum forming. 2. Since the convex mold is inserted into the inner part shaped like a hemisphere, the corners of the mold do not strongly contact the sheet, resulting in fewer drag lines. 3. When free-blowing, the hemispherical ceiling part is well stretched, and when it is vacuum-adsorbed to the mold, the side wall part is also stretched, resulting in relatively less uneven thickness. 4. The strength of the formed product increases as it is stretched in two axial directions.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Blister packs are created by vacuum forming transparent plastic sheets (PET sheets) to match the design of the product to be packaged. The product is placed in the raised areas formed during the molding process and then sealed onto a backing card for packaging. This allows for detailed inspection of the product's shape, and it is widely used across various fields. It is suitable for displaying items such as brushes, stationery, toys, and tools, providing a package that highlights the product while keeping it dust-free. Additionally, there are easy-to-set-up shell packs that leave a good impression in retail spaces, as well as slide packs that allow for setup by sliding the backing card. By encasing the product in a transparent pack and conforming to its shape, the product is secured while also enhancing its visual appeal. It is resistant to vibrations and impacts, preventing damage to the product, making it highly versatile. This convenient packaging can be hung or stood up without taking up much space, allowing for flexible display options.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Most heating methods involve either radiative heating of sheets stretched in space using infrared or heating air with hot air, but direct heating vacuum forming is a method that heats and forms sheets by closely adhering them to a properly temperature-controlled heating plate. 【Features】 1. By managing the surface temperature of the heating plate, uneven heating does not occur, resulting in uniform and stable molded products. 2. The heating time is shorter due to contact heat conduction between solids, being a fraction of the time required for the radiation heating method that involves air. 3. There is little heat dissipation, making it efficient. 4. A large number of exhaust holes are required to expel the air between the heating plate and the sheet, leading to high production costs for the heating plate. 5. Auxiliary means such as plug-free blow cannot be used, resulting in only shallower molded products compared to straight vacuum forming. 6. In the case of multiple parts, the influence of adjacent molds can affect the outcome. 7. As the molded product cools, it may shrink in the direction that tightens against the mold, making demolding difficult. 8. Sufficient draft angles for demolding must be provided, or if there are slight undercuts, a knockout device will be necessary. 9. In deep draw vacuum forming, when pushed up and stretched, the sidewall portion is elongated in one direction, creating directionality in the molded product and reducing lateral strength.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

To produce sheet loss (raw material loss) without waste, we carry out vacuum forming processing and automatic trimming, and simultaneously conduct a consistent automatic production of plastic containers up to the sheet crushing process. For environmental measures and waste management, we use biodegradable plastics that are in harmony with the environment, primarily made from starch derived from grains, which are decomposed by microorganisms into water and CO2 (carbon dioxide), without generating dioxins or harmful substances. We are also engaged in the development of low-pollution containers, conductive trays, blister packs, and other products. Our company has been involved in vacuum forming of plastic containers and blister packs in Osaka City for many years while continuing to pursue technological development.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Matsuba Giken has established a quasi-clean room. In the case of food trays, they are containers for food, and it is prohibited for them to be contaminated with garbage, dust, scrap, small insects, hair, oil, etc. When entering the factory, one must brush their hair 20 times, wear a double-structured work uniform, put on an electrostatic cap to prevent static electricity, and then wear a hood over it. Inside the air shower room, one must rotate their body three times, and afterward, either use a sticky roller with two people facing each other or roll in front of a full-length mirror. Raw materials are brought in after removing garbage and dust inside a double door, stored under a sterilization lamp for 20 minutes, and then passed through the entrance room to enter the factory. Based on vacuum forming data, test products and actual products are distinguished at the start of the flow; all test products are discarded, and only the actual products are processed, confirming that there is no misalignment with the moving blade during the work. The tetrahedral formed products are visually inspected, and then packaged into bags and boxes through a dust collector.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

【Disadvantages】 1) Can it be applied to the mold? It is impossible to apply 0.5mm, 1mm, or 2mm to the mold. 2) Is the cost of the material itself high? Injection molding uses resin as is, but vacuum forming requires the resin to be extruded into a sheet form and then processed further, which increases the material cost. 3) Why is the cost of fabric loss relatively high? Molded items always require finishing, and unnecessary parts need to be trimmed, which adds to the cost. 4) Why does the thickness vary in certain areas due to shape? The corners tend to stretch and become thinner depending on the height (depth) of the product. 5) Why do the inner and outer dimensions of the molded product have different thicknesses? There is variation in thickness accuracy between the side facing the mold and the side not facing it. 6) Why do the inner and outer dimensions of the molded product have different thicknesses? It is impossible to achieve high precision molding for shapes with fine and deep details.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

【Merits】 1) Is the delivery time for molds fast? The prototype delivery time is about 3 to 6 days. The mold delivery time is about 3 weeks. 2) What is the price of the molds? Processing is easy and material costs are low. It can be completed at about 1/10 the cost of blister packs. 3) Is it easy to modify designs and shapes? Changes and repairs to the molds can be easily made. Since it is a separate process from the cutting die, modifications may not be necessary. 4) Is it possible to change the thickness of the materials? It is possible to produce with a different thickness from the prototype. It is also possible to produce using a plug from the prototype. 5) Can molding be done with both concave and convex shapes? It is possible to utilize features according to the application. Generally, blister packs are made with convex shapes. Trays are typically made with concave shapes. 6) Is it possible to produce small lots and a variety of products? Small production runs and combinations are possible. For prototypes, it is possible to produce between 10 to 100 pieces. 7) Can prototypes be molded with different materials? Molding with different materials such as PET, PS, PP, ABS, PPF, etc. is also possible.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

<<Metal Molds>> Iron, aluminum alloys, zinc alloys, and bronze are used, each with distinct characteristics that make selection difficult. Generally, smaller items are better suited for zinc alloy bronze and aluminum alloys, while larger items are more appropriate for aluminum alloys. [Characteristics] - Iron is relatively inexpensive compared to other metals, but it is not widely used due to rusting and the difficulty of machining exhaust holes. - The surface of cast items is best with zinc alloy, but pressure casting can produce aluminum alloys with minimal finishing required. - Both bronze and zinc alloys have good machinability without issues, while aluminum alloys have inferior workability. - Small items are not affected by weight, but larger items are better suited for aluminum alloys due to their light weight. - They have good thermal conductivity, making temperature control of the mold relatively easy and suitable for high-speed molding.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

<<Thermosetting Resin Type>> The materials include resins such as epoxy, polyester, and phenol, which are often used with reinforcing agents and fillers. [Features] - While a mirror finish cannot be achieved, it can be finished very well. - Compared to wood and plaster, it has significantly higher strength and can be used for mass production. - Cooling time is long. Drag lines do not appear much. Deformation during release is minimal. - It has a high thermal expansion, and continuing the molding process can lead to increased temperature, expansion, or distortion. It is not suitable for molded products that require precision. - Repairing molds and changing designs is easy, and due to its strong adhesion and good workability, corrections can be made easily.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

<<Gypsum Mold>> 【Features】 If bubbles do not appear on the surface, smooth and fine patterns can be expressed. Thin cuts of meat and angular items are prone to chipping. The surface condition is good, and it has considerable durability, allowing for the production of high-quality molded products in small quantities, prototypes, and medium-scale production. The molding cycle is long, and drag lines do not appear strongly. There is little deformation, and compared to wood, the thermal conductivity is about ten times greater. It is suitable for prototypes and small-batch production of various types and can be produced at a low cost. Thermosetting resin mold Materials include resins such as epoxy, polyester, and phenolic, which are often used with reinforcing agents and fillers.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

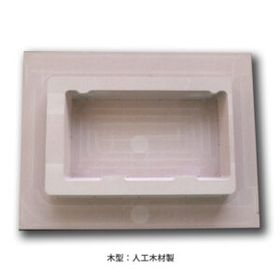

<<Artificial Wood Mold>> 【Features】 - Artificial wood molds are made of high-density foamed synthetic resin, which does not develop directional properties or cracks during molding, unlike wooden molds. - Being made of foamed synthetic resin, they are easy to adapt to NC machines and are suitable for dimensional accuracy and shape. - Due to poor thermal conductivity, they have long molding cycles and are not suitable for mass production. - The surface of artificial wood molds is rough because they are made of foamed synthetic resin, resulting in molded products lacking transparency (suitable for prototypes). - Poor thermal conductivity and cooling can lead to deformation of molded products. - They can be produced at a low cost due to excellent material cost and workability, as well as ease of modification.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The prototype uses artificial wood and wooden molds. The main mold uses either a cast mold or an aluminum mold, which provides good transparency and excellent cooling, thereby improving production efficiency. Plugs and water-cooled plates may be unnecessary depending on the shape. Generally, existing water-cooled plates are used. *The mold is aluminum (AI), but there are also cast molds (porous).

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration