マツバ技研工業

Contact this company

Inquiry Form

マツバ技研工業 Company Overview

For plastic molding processing using vacuum forming, contact Matsuba Giken Kogyo.

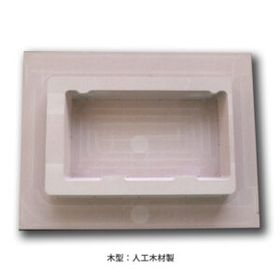

There are various molding methods for plastic molding processing, but our company's vacuum forming (vacuum molding) has lower mold costs compared to other molding methods and allows for small lots of a wide variety of products. This enables us to mass-produce plastic containers at a low cost within a quasi-cleanroom factory. Additionally, due to its high versatility, plastic containers such as conductive trays, frozen food containers, cosmetic trays, blister packs, barrier trays, clear cases, and biodegradable plastics are used in various fields.

Business Activities

We are a specialized manufacturer of original products such as vacuum-formed plastic containers, blister packs, trays for medical supplies, food trays, parts trays, frozen food trays, cosmetic trays, conductive trays, and biodegradable plastics. We are committed to cost reduction through continuous improvement and enhancements, and we work on a production management system within production facilities that are equipped with quasi-clean room standards for vacuum-formed plastic containers.

Products/Services (54)

catalog(3)

Survey responses are required to view e-book details. Click to view the e-book.

news(23)

Detailed information

| Company name | マツバ技研工業 |

|---|---|

| number of employees | 26 |

| Contact address | postalcode 547-0002 Osaka/ Hirano-ku, Osaka-shi/ 1-13-46 Kamiedō, JapanView on map TEL:06-6792-2829 FAX:06-6792-8151 |

| Key Partners | We are a specialized manufacturer primarily focused on vacuum-formed plastic products such as plastic containers, frozen food trays, blister packs, conductive trays, electronic component trays, medical trays, and cosmetic trays, including biodegradable plastic trays, all produced in a quasi-clean room environment. Using thin plastic sheets and the vacuum forming process, we employ an inexpensive die called Thomson with an automatic puncher to simultaneously perform trimming and accumulation. Our manufacturing equipment is designed to minimize sheet loss by even grinding the sheets, enabling a consistent automatic production of plastic containers. To achieve cost reductions, we continuously improve and refine our vacuum forming machines and work on our production management system, ensuring that the quality control of vacuum-formed plastic containers is the foundation of our manufacturing process within the quasi-clean room production facilities. Funai Electric, Meiko Industry, Fuji Industry, Fuji Seal, Matsuno Industries, Japan Matai. |

| Industry | Resin/Plastic |

マツバ技研工業 Building Image

マツバ技研工業 Building Image

![[Case Study] Vacuum Forming Frozen Food Tray](https://image.mono.ipros.com/public/catalog/image/01/170/600969/IPROS63374966474164074851.jpeg?w=120&h=170)