1~20 item / All 20 items

Displayed results

Filter by category

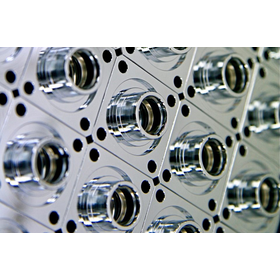

Surface treatment technology

Introduction to Surface Treatment Technology