南海モルディ株式会社(旧:南海鋼材株式会社)

Contact this company

Contact Us OnlineBefore making an inquiry

Download PDF

南海モルディ株式会社(旧:南海鋼材株式会社) Company Profile

We will respond with speed and sincerity.

For the sake of our employees, our customers, our suppliers, and society, we express our gratitude for the company's development and will always remember to find joy in contributing to society while diligently working in our business.

Business Activities

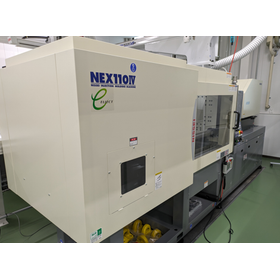

Manufacturing and sales of forging molds and mold components Manufacturing and sales of die-casting mold components Sales of die sets for forging presses Processing and sales of castings for die-casting molds Processing and sales of other molds and mold components Manufacturing and sales of various jigs and tools Sales of mold cleaning equipment and other mold-related facilities Sales of cutting tools for special steel, tool steel, and mold steel Sales of raw materials (forging, casting) and raw products Outsourcing of mold and mold component processing overseas

Recommended information

Die Casting Aluminum Melt Plunger System MOHF (Mof)

Special resin adopted for the die casting plunger system * Suppresses galling and backflash within the sleeve due to high heat resistance and high durability.

Traditionally, the use of resin in the plunger system was unimaginable in the world of aluminum die casting. ~Part Characteristics~ 【Special Resin】 High heat resistance and durability suppress galling and backflash within the sleeve. 【Surface Treatment】 Special treatment retains lubricating oil, suppressing galling. 【Special Welding】 A special metal with low affinity for aluminum is coated (with a buildup process), suppressing aluminum melting. ~Effects~ * Prevention of chocolate stops due to galling suppression. * Extension of sleeve life due to backflash suppression. * High aluminum filling rate achieved through resin filling within the sleeve. * Suppression of aluminum temperature rise due to high thermal insulation. The structure is also very simple, reducing replacement effort (which is a welcome aspect for everyone on-site). The combination of part characteristics is flexible and can be customized according to user preferences. We kindly ask you to consider the new stance of the plunger system, 【MOHF】.

Reinforcement and repair of screw products!

Weld high-alloy powder onto worn or damaged screws! It is possible to enhance strength for products with shape restoration, wear resistance, and corrosion resistance.

Are there any worn or damaged screws? Are you struggling with insufficient strength? In that case! With our original system, "Nikumori-kun," we can restore the shape of damaged components and increase strength by using plasma arc or laser light to add high-alloy powder. Parts that are consistently worn can be repaired with buildup, allowing for repeated use. Instead of remaking the entire product, we can enhance performance at a low cost by adding high-alloy powder only to the necessary areas. Additionally, our robotic welding using "Nikumori-kun" enables uniform and stable processing.

Products/Services (24)

catalog(22)

Survey responses are required to view e-book details. Click to view the e-book.

news(5)

Detailed information

| Company name | 南海モルディ株式会社(旧:南海鋼材株式会社) |

|---|---|

| number of employees | 160 |

| Contact address | postalcode 590-0007 Osaka/ Sakai-shi, Sakai-ku/ 2-2-10 Kitazho-machiView on map TEL:072-233-1525 FAX:072-233-0172 |

| Business Locations | Click here for the list |

| Industry | Industrial Machinery |

南海モルディ株式会社(旧:南海鋼材株式会社) Building Image

南海モルディ株式会社(旧:南海鋼材株式会社) Building Image