1~44 item / All 44 items

Displayed results

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Contact this company

Contact Us OnlineBefore making an inquiry

Download PDF1~44 item / All 44 items

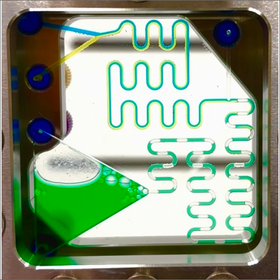

Our company designs and develops equipment for research and development, such as glass microreactors that allow for clear observation of liquid flow, and continuous flow experimental devices that can control flow rate, temperature, pressure, and more in a unified manner. We can provide equipment that accommodates long hours of continuous operation and multi-stage reaction processes, taking into account reproducibility and scale-up. 【Features of Glass Macroreactors】 - No sealing materials used, making disassembly and cleaning easy. Reusable. - Custom design of flow paths is supported, adaptable for flow photoreactions. 【Features of Continuous Flow Experimental Devices】 - Data logging capability allows for real-time monitoring. - Easy optimization of reaction conditions, enabling efficiency and labor-saving through automation. *We are currently offering free materials summarizing our developed products and use cases. You can view them by downloading the catalog. Please feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Integrated Microreactor Lineup ◇ 2x2 Type: 4 channels each for A and B, up to 500 ml/min ◇ 4x4 Type: 16 channels each for A and B, up to 1.5 L/min ◇ 8x8 Type: 64 channels each for A and B, up to 3 L/min Features of Integrated Microreactors ◆ Compact size ◆ Disassembly and cleaning possible ◆ Maximum processing capacity of 3000 ml/min ◆ Compatible with liquid-liquid, gas-liquid, and gas-gas mixing ◆ Applicable for recrystallization ◆ Materials: SUS316L, Hastelloy, nickel, etc., resistant to chemicals

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

New Release: Continuous Flow and Automation of Liquid-Liquid Separation Funnels! Smooth extraction and separation with the slug flow effect. We would like to introduce our "Continuous Automated Mixer Settler." The integration of a Y-shaped mixer and settler achieves a compact flow. It has been proven to operate non-stop for one week with interface control. The experimental operations are fully automated, enabling multi-stage extraction and separation for laboratory automation of small-scale plants. Additionally, with safety features, it allows for long hours of reliable operation and can be easily operated via a touch panel. 【Features】 ■ Proven non-stop operation for one week with interface control ■ Automation and labor-saving of experimental operations ■ Precise extraction through multi-stage extraction and separation ■ Easy operation with a touch panel ■ Safe long-term operation with reliable safety features *For more details, please refer to the related links or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This technical report presents examples of lab-scale continuous flow synthesis (continuous production) using a "normal pressure micro-scale CSTR." The goal of this article is to demonstrate that "flow reactors can be used in ordinary organic synthesis conducted in typical research and development (lab scale), meaning that by performing continuous flow synthesis under reaction conditions equivalent to batch synthesis, it is possible to obtain the target product with yields comparable to those of batch synthesis." We encourage you to read it. [Contents (partial)] ■ Introduction ■ Continuous flow esterification reaction ■ Batch synthesis (preliminary study) ■ Continuous flow synthesis ■ Equipment *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

With a separatory funnel, there were issues such as "danger from swinging glass containers," "variability in results depending on the operator's skill," and "difficulty in automation." Therefore, by integrating a Y-shaped mixer and a settler into a "mixer-settler," it is possible to streamline the process of using a separatory funnel. This allows for continuous processing, and since the conditions are set numerically, anyone can achieve the same results, requiring minimal manual labor. 【Features】 ■ The device is fixed ■ Conditions are set numerically, so anyone can achieve the same results ■ The process can be continuous ■ Processing in small amounts means gas generation is not an issue ■ Minimal manual labor is required ■ Automation is possible *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Experiments on chemical processes necessary for the development of pharmaceuticals, such as synthesis, mixing, extraction, separation, recrystallization, hydrogen reduction, and cleaning, can be conducted in a continuous flow system. Precise control of temperature, flow rate, and pressure contributes to safe operation and accelerates research and development. Materials can be changed to suit chemical resistance (SUS316L, nickel alloy, PTFE, glass, etc.). We support the possibility of continuous production through the design and manufacture of flow reactor systems. 【Products Offered】 ■ Microreactors (precise mixing, ultrafine particles) ■ Integrated microreactors (with scale-up options) ■ Micro-scale CSTR (hydrogen reduction, recrystallization) ■ Mixer settlers (extraction/separation, cleaning, continuous flow of separating funnels) ■ Microwave irradiation flow reactors (reducing reaction time through internal heating) 【Available Equipment for Rental Lab】 ○ Analyzers (liquid chromatography (HPLC), gas chromatography, ReactIR, microscope, etc.) ○ Various pumps (syringe, diaphragm, tube, mono, etc.) *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This technical report includes a section on "Talk" from the Mac Technical Report. In the previous Mac Technical Report "Talk003," it was stated that "in factories where chemical products are mass-produced, there are generally two types of reactors used for continuous production (PFR and CSTR), and it is common to use these two types on a case-by-case basis, taking into account their respective advantages and disadvantages." In response to this, I will explain how to differentiate between the two types while providing some specific examples. [Contents (partial)] ■ Introduction ■ PFR (Plug or Piston Flow Reactor) ■ Main advantages of PFR ■ Main disadvantages of PFR ■ CSTR (Continuous Stirred Tank Reactor) *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This technical report features the "Talk" section of the Mac Tech Report. Following the previous issue (Mac Tech Report Talk_001), this time we present "The First Continuous Production Using Micro-scale CSTR (Part 2)," detailing specific experimental procedures. The theme of this experiment is "Continuous (Flow-type) Ester Exchange Reaction," and, like the previous issue, it is positioned as a practice experiment. Unlike the previous continuous crystallization, this theme is more representative of organic synthesis practice experiments, as it typically involves reflux and other processes. [Contents] ■ Introduction ■ Continuous (Flow-type) Ester Exchange Reaction ■ Overview of Operating Procedures ■ Experiment Overview *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Here is an example of "Purification of Organic Matter Using a Mixer Settler" that we are conducting. Benzoic acid is removed from a mixture of naphthalene and benzoic acid through acid-base extraction, resulting in a purified solution of naphthalene only. The purity is equivalent to or greater than that achieved by batch methods, with a recovery rate of over 99%. 【Example】 - Benzoic acid is removed from a mixture of naphthalene and benzoic acid through acid-base extraction, resulting in a purified solution of naphthalene only. - The purity of naphthalene is equivalent to or greater than that achieved by batch methods. - The recovery rate of naphthalene is over 99%. *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Sealed Micro Scale CSTR" is a flow reactor with a main body (material SUS316L) that can withstand a maximum pressure of 0.9 MPa. There are no flow blockages, and it allows for continuous injection and extraction of the catalyst (Pd/C) slurry. Additionally, by replacing it with a glass inner lid, the interior of the reaction vessel becomes visible. 【Features】 ■ No flow blockages ■ Continuous injection and extraction of the catalyst (Pd/C) slurry ■ Pressure resistance of the CSTR main body (material SUS316L): maximum 0.9 MPa ■ No concerns about pressure loss ■ Heating and cooling capabilities ■ The interior of the reaction vessel can be seen by replacing it with a glass inner lid *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Continuous flow experiments can be conducted for chemical processes necessary for the development of pharmaceuticals, including synthesis, mixing, extraction, separation, recrystallization, hydrogen reduction, and cleaning. Testing is currently being accepted at our lab. 【Microreactor】 - Precise control and acceleration of mixing, heat transfer, and reactions ⇒ High performance and functionality - Miniaturization of devices and systems ⇒ Resource-saving, energy-saving, and decarbonization - Capability to operate under harsh reaction conditions (explosion avoidance) ⇒ Improved safety - Standard material is SUS316, with compatibility for various materials such as Hastelloy, niobium, tantalum, and glass. 【Mixer Settler】 This is a "pushing flow type" tubular reactor. It is suitable for the continuous processing of post-reaction treatments (extraction/cleaning, separation, etc.). *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This document is "Applications_002" from the Mac Technical Report, which contains the user manual for the mixer-settler. It is a continuous device as shown in Mac Technical Report Products_001 - Continuous Equipment Lineup. This document illustrates how to use the equipment. Please take a moment to read it. 【Contents (partial)】 ■ Mixer-settler device details ■ Mixer-settler ■ Pump ■ Slag flow tube ■ Flow adjustment *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This document is "Applications_001" from the Mac Technical Report, which reports the results of acid extraction experiments using a mixer-settler. It examines the extraction efficiency when extracting acid with a continuous system compared to batch extraction. I believe this information will be useful as basic data for the equipment. Please take a moment to read it. 【Contents (partial)】 ■ Mixer-settler acid extraction experiments ■ Acid extraction experiments ■ Batch extraction ■ Mixer-settler system ■ pH measurement *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We have decided to divide the traditional Mac Technical Report into three thematic sections to deliver to our readers. This document introduces the "Talk" section of the Mac Technical Report. The theme is "Various topics related to continuous production (continuous flow synthesis) and useful information you should know." The intended audience is researchers (commonly referred to as experimentalists) who have learned organic synthesis and conducted experiments, but are approaching continuous production (continuous flow synthesis) at the lab scale for the first time. [Contents] ■ Introduction ■ First Continuous Production Using Micro-scale CSTR ■ Continuous Crystallization of Salt (MSMPR) ■ Overview of Operating Procedures ■ Experimental Observations *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Continuous flow experiments can be conducted for chemical processes necessary for the development of pharmaceuticals, including synthesis, mixing, extraction, separation, recrystallization, hydrogen reduction, and cleaning. Testing is currently being accepted at our lab. 【Microreactor】 - Precise control and acceleration of mixing, heat transfer, and reactions ⇒ High performance and functionality - Miniaturization of devices and systems ⇒ Resource-saving, energy-saving, and decarbonization - Capability to operate under harsh reaction conditions (explosion avoidance) ⇒ Improved safety - Standard material is SUS316, with compatibility for various materials such as nickel alloys, niobium, tantalum, and glass. 【Mixer Settler】 This is a tubular reactor of the "extrusion flow type." It is suitable for the continuous processing of post-reaction treatments (extraction/cleaning, separation, etc.). *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Continuous flow experiments for chemical processes necessary for the development of pharmaceuticals, such as synthesis, mixing, extraction, separation, recrystallization, hydrogen reduction, and cleaning, are available. Testing is currently being accepted at our lab. 【Microwave Irradiation CSTR】 - Significantly speeds up reaction rates with rapid heating - Uniform heating through internal heating at the molecular level - Improves reaction efficiency and energy savings when combined with continuous equipment - Enables the creation of new reactions and simplification of existing processes 【Microscale CSTR】 - A fully mixed continuous flow reactor scaled down to microscale for experimental use - Extremely smooth transition from batch synthesis to continuous flow synthesis - Capable of heating, cooling, high pressure, microwave, light reactions, crystallization, etc. - The main materials are SUS316L, PTFE, and Teflon, with options for other materials like Hastelloy - The content volume of a single reaction vessel is approximately 3ml, with a total of about 15ml for 6 vessels *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Compact Piezo Pump Mixer Settler" sends liquid from a small piezo pump to an integrated Y-shaped mixer, which generates a slug flow. It utilizes the circulating flow within the connecting tube for extraction. After extraction, liquid-liquid separation occurs in the settler tank on the same plate. This compact device is suitable for continuous processes such as extraction, washing, and separation. We also offer "mixer settlers" that are ideal for the continuous processing of post-reaction treatments. 【Features】 ■ Liquid is sent from a small piezo pump to the integrated Y-shaped mixer ■ Slug flow is generated by the Y-shaped mixer ■ Extraction utilizes the circulating flow within the connecting tube ■ After extraction, liquid-liquid separation occurs in the settler tank on the same plate ■ Two-stage connection can improve extraction efficiency *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Micro Scale CSTR (Hybrid Type Main Body)" is designed to prevent (reduce) backflow and short-circuiting of the reaction liquid. In the flow path connecting the tanks, "grooves" and "holes" are arranged alternately. The volume of one reaction tank is approximately 3 mL, and the liquid filling amount for this product is about 14 mL. The main body materials available are SUS316L, PTFE, and Tokabait TK11. 【Features】 ■ "Hybrid": A type of micro scale CSTR main body for atmospheric pressure ■ Alternating arrangement of "grooves" and "holes" in the flow path connecting the tanks ■ Designed to prevent (reduce) backflow and short-circuiting of the reaction liquid ■ Main body materials include SUS316L, PTFE, and Tokabait TK11 (Other materials such as Hastelloy can also be accommodated as options) *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In this document, we present three main types of equipment that have been manufactured utilizing our precision machining capabilities, as well as projects currently under development. We offer a lineup that includes the "Standard Microreactor," the "Integrated Microreactor," and the "Atmospheric CSTR." Additionally, we introduce mixer settlers and equipment under development. We encourage you to read through it. 【Contents】 1. Overview of Continuous Flow Systems 2. Microreactor (Tubular Reactor: PFR) 3. Micro-scale CSTR (Continuous Stirred Tank Reactor) 4. Mixer Settler 5. Equipment Under Development 6. Conclusion *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Continuous flow experiments can be conducted for chemical processes necessary for the development of pharmaceuticals, including synthesis, mixing, extraction, separation, recrystallization, hydrogen reduction, and cleaning. As it is a small-scale experiment, it contributes to the stabilization of control over temperature, flow rate, and pressure, safe operation, reduction of reagent costs, and acceleration of research and development. Materials can be changed according to chemical resistance (SUS316L, nickel alloys, tantalum, glass, PTFE, Peek, etc.). We support the possibility of continuous production by manufacturing original reactors. ★ Materials related to flow reactor synthesis can be viewed via PDF download. 【Products Offered】 ■ Microreactors ■ Integrated microreactors (with scale-up options) ■ Micro-scale CSTR (Continuous Stirred Tank Reactor) ■ Mixer-settlers (extraction, cleaning, separation) ■ Microwave irradiation flow reactors (under development) *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This technical report covers the "reaction liquid extraction device," which is essential for our micro-scale CSTR (Continuous Stirred Tank Reactor) products. In a previous report (Mac Tech Report 20TR03-3), we introduced the use of a tube pump (roller pump), but we were extracting the reaction liquid by putting a bit of strain on the pump. Therefore, we are now introducing a "reaction liquid extraction device" that allows the tube pump to be used without any burden. [Contents] ■ Device ■ Usage examples *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The theme of this technical report is "Continuous Contact Hydrogenation using CSTR." In order to expand the application range of our micro-scale CSTR, we have implemented various innovations, such as combining prototypes. In a previous report (Mac Tech Report 20TR04, section 4-3-3), it was stated that "investigation of solid transfer methods is necessary," and we believe that one answer has been obtained from this experiment. However, detailed examination is still lacking, so we will simply present the facts. [Contents] ■ Reaction ■ Equipment and accessories ■ Operation ■ Results ■ Remarks *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This report continues from the previous one and features an introduction to useful sites related to Flow Chemistry (hereafter referred to as FC), specifically the "Companies" section (Part 2). There are more FC-related companies (both domestic and international) than one might think, so it is not possible to introduce them all. We appreciate your understanding. [Contents] ■ FC-related companies ■ Companies selling micro-scale organic synthesis experiment kits (carefully selected 3 companies) *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This technical report presents useful websites related to Flow Chemistry (hereinafter referred to as FC). There are many, but to avoid overwhelming you, we have carefully selected and will introduce them in two parts: "Part 1: Journals, Consortiums, etc., Public Institutions" and "Part 2: Companies." First, here is "Part 1: Journals, Consortiums, etc., Public Institutions." Please take a moment to read it. [Contents] ■ Journal websites (3) ■ Consortium websites (5) ■ Public research institution websites (3) *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This technical report presents an example of esterification using a micro-scale CSTR. While PFRs (e.g., microreactors, tube reactors, column reactors) have become more commonly seen in papers, CSTRs are still relatively rare. Therefore, we will specifically convey how reactions were conducted using our product, "CSTR (micro-scale)." We encourage you to read it. [Contents] ■ Reaction ■ Equipment and accessories ■ Operation ■ Results and discussion ■ Notes *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

When it comes to devices that are unique to "continuous flow synthesis," it is undoubtedly the liquid delivery pump. When you actually assemble (systematize) the experimental setup, you will likely be surprised by the large number of pumps involved. On the other hand, having a large number of pumps means that adjustments (flow rate, operation timing, and the quirks of each pump) are necessary. In this technical report, we feature various types of pumps, including "syringe pumps," "diaphragm pumps," and "mono pumps," along with photographs. We encourage you to read it. [Contents (excerpt)] ■ Device unique to "continuous flow synthesis" = liquid delivery pump ■ Syringe pump ■ Tube pump (roller pump) ■ Plunger pump *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

When conducting organic synthesis in the lab, one might easily assume that similar equipment (e.g., flasks, separatory funnels, rotary evaporators, distillation columns, suction funnels, etc.) is used in production facilities (factories) as well, albeit in different sizes. However, this is a significant misconception. This report includes "Continuous Flow Synthesis in Production Facilities (Factories)" and "Various Experimental Tools for Continuous Flow Synthesis: PFR Edition and CSTR Edition." We encourage you to read it. [Contents] ■ Continuous Flow Synthesis in Production Facilities (Factories) ■ Various Experimental Tools for Continuous Flow Synthesis: PFR Edition ■ Various Experimental Tools for Continuous Flow Synthesis: CSTR Edition *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The main theme of Mac Tech Research is "Continuous Flow Synthesis." The target audience is researchers (commonly referred to as experimentalists) who have learned and conducted organic synthesis but are attempting continuous flow synthesis (at the lab scale) for the first time. In recent years, many people have been keenly aware of the trend towards continuous production in industries such as pharmaceuticals. At the same time, I feel that there are quite a few individuals who, despite their interest, are struggling due to a lack of prior information. Therefore, through this technical report, we hope to provide some of the missing information, and we would be pleased if it can be of some assistance to our readers. [Contents] ■ Introduction ■ About Continuous Flow Synthesis ■ About Microscale Organic Synthesis *The technical document "Mac Tech Research" can be fully viewed by downloading the PDF.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce the main equipment owned by Mack Engineering Co., Ltd. Our company specializes in precision parts processing, mold parts processing, and high-hardness processing. We possess various equipment, including five-axis machining centers, NC compound Y-axis lathes, fine hole discharge machining machines, and general-purpose milling machines. We respond to our customers' needs with quick and high-precision integrated manufacturing through various NC machines for compound processing and simultaneous three-axis shape processing. 【Equipment Overview (Partial)】 ■ Five-axis machining center ■ NC discharge machining machine ■ Fine hole discharge machining machine ■ Three-dimensional measuring instrument ■ Fluid analysis device *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We have established a new experimental laboratory, "Flow Reactor Research Rental Lab," within our factory. The lab is fully equipped with various measuring instruments and inspection tools, including high-speed automatic cameras, 3D measuring machines, 3D CAD, and fluid analysis devices. You can actually verify the performance of the flow reactor. In addition, there is a "new rental lab within the Flow Reactor Development Center" where experiments on microreactors, micro CSTRs, and mixer settlers can be conducted. We are accepting reservations for the rental lab, so please feel free to consult with us. 【Features】 <Flow Reactor Research Rental Lab> ■ Experiments can be conducted with microreactors and pump sets ■ Equipped with various measuring and inspection instruments (High-speed automatic cameras, 3D measuring machines, 3D CAD, particle analysis devices, etc.) ■ Development, design, manufacturing, and sales of microreactors are allowed *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Micro Scale (R) CSTR" is a completely mixed tank reactor. It connects six tanks with the same functionality as a micro vial. This achieves efficient continuous stirring. Compared to traditional batch methods using flasks, it offers overwhelming advantages in reaction characteristics, quality, safety, productivity, energy efficiency, space-saving, initial investment costs, and precision control. 【Features】 ■ Efficiently centralizes precise mixing, reaction, extraction, and concentration ■ Connects six tanks with the same functionality as a micro vial ■ Achieves efficient continuous stirring ■ Custom-made options available according to application ■ Visible observation from the top *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "OKM-SO1/SO2" is an ultra-compact plant made of stainless steel flow path plates that are easy to disassemble and clean. There are two types available: the standard model "OKM-S01" and the transparent model "OKM-S02." The flow path plates can be customized in terms of material and flow path shape. It is expected to be utilized in various fields such as medical, pharmaceuticals, science, environment, energy, biotechnology, food, and functional materials. 【Features】 ■ Palm-sized ■ Standard flow path plate: thickness 0.3mm, flow path width 0.15mm ■ Easy disassembly and cleaning with stainless steel flow path plates ■ Various experiments can be conducted by simply replacing the flow path plates ■ Flow path plates can be customized (material, flow path shape, etc.) *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Micro Scale CSTR" is a continuous stirred-tank reactor that makes it easy for chemical synthesis researchers to consider scale-up. The image shows six micro vials connected in series by a slit. However, the center part is shallow at the bottom for reagent input. A new model that can be used for multiple purposes is also expected to be released soon. If you are looking for flow reactors, please contact our company, which offers both types (PFR & CSTR). We also have a rental lab where you can actually test either type of reactor. 【Features】 ■ Makes it easy for chemical synthesis researchers to consider scale-up ■ A new model that can be used for multiple purposes is also expected to be released soon ■ Both types (PFR & CSTR) are available ■ There is also a rental lab where you can actually test either type of reactor *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Continuous Flow Mixer Settler" is easy to disassemble and clean, and allows for observation. It enables continuous extraction, separation, and cleaning. Slag particles are generated using a Y-shaped mixer. Extraction can be adjusted by the length of the tube, and separation can be adjusted by the thickness of the settler plate. 【Features】 ■ Continuous flow type ■ Continuous extraction, separation, and cleaning ■ Slag particle generation with a Y-shaped mixer ■ Extraction adjusted by tube length, separation adjusted by settler plate thickness *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

There are two types of continuous reactors (flow reactors)! 1. Microreactor (Tubular Reactor: PFR) - Precise control and acceleration of mixing, heat transfer, and reactions ⇒ High performance and high functionality - Enables operation under harsh conditions such as nitration (avoiding explosions) ⇒ Improved safety - Miniaturization of equipment and systems ⇒ Resource and energy savings 2. Microscale (Continuous Stirred Tank Reactor: CSTR) - A fully mixed continuous stirred tank reactor miniaturized for experimental use - Extremely smooth transition from batch synthesis to continuous flow synthesis - Capable of heating, cooling, high pressure, microwave, light reactions, crystallization, etc. 3. Mixer Settler (Extraction, Separation, and Washing Device) - Suitable for continuous post-processing (extraction, washing, phase separation, etc.) after reactions - Generates a slug flow in a Y-shaped flow path, achieving continuous separation in tanks on the same plate - Possible to realize a flow process for post-processing by connecting devices in multiple stages ■ Equipped with various measurement and inspection instruments ■ Development, design, manufacturing, and sales are OK ■ Rentals available at the "Microreactor Research Lab" - Over 50 types of microreactors available *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Micro Scale CSTR" is a fully mixed continuous stirred tank reactor (CSTR) that has been micro-scaled for experimental use, developed over many years of refinement. Adjacent reaction tanks are connected, with the volume of one reaction tank being approximately 3ml, resulting in a total volume of 20ml for six tanks. In synthetic scale, this corresponds to about 2ml x 6. The transition from batch synthesis to continuous flow synthesis is extremely smooth, and processes such as heating, cooling, high pressure, microwave, photoreaction, and crystallization are also possible. 【Features】 ■ Fully mixed type micro-scaled CSTR for experimental use ■ Adjacent reaction tanks are connected ■ Extremely smooth transition from batch synthesis to continuous flow synthesis ■ Capable of heating, cooling, high pressure, microwave, photoreaction, crystallization, etc. *For more details, please refer to the external link page or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "microreactor" is a cutting-edge device that transforms research and development environments as well as production sites. By adopting interchangeable flow path plates, it has achieved diversification compared to conventional custom-made products. Despite being a standard product, there are over 50 different patterns of flow path plates. By swapping plates and changing the flow paths, it becomes possible to conduct various experiments under different conditions with just this one device. 【Features】 ■ Precise control and acceleration of mixing, heat transfer, and reactions ⇒ High performance and high functionality ■ Enables operation under harsh conditions such as melting (explosion avoidance) ⇒ Improved safety ■ Miniaturization of devices and systems ⇒ Resource-saving and energy-saving *For more details, please refer to the external link page or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "microreactor" is a component of a device that performs chemical reactions and is an advanced experimental tool used in the research and development of new drugs at universities and companies. Compared to the previous methods of mixing reagents in beakers and test tubes, it reacts several dozen times faster and yields high-purity results. Additionally, because experiments can be conducted in a small space, it contributes to the efficiency and simplification of work. 【Features】 ■ For research and development of new drugs ■ Capable of conducting tens of thousands of experiments with small amounts of reagents ■ Economical ■ Experiments can be conducted in a small space ■ Contributes to the efficiency and simplification of work *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Micro Scale CSTR" enables high quality and high efficiency in continuous flow. Continuous flow is possible even for reactions that are prone to crystallization. We can accommodate from small to large quantities. Additionally, testing is available at our rental lab. Please feel free to contact us when selecting a continuous reactor. 【Features】 ■ Makes it easy for chemical synthesis researchers to consider scale-up ■ Continuous flow is possible even for reactions that are prone to crystallization ■ Accommodates from small to large quantities ■ Stabilizes continuous flow reactions by connecting with microreactors ■ Enables high quality and high efficiency in continuous flow *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce our extrusion flow type (tube reactor) "Microreactor" and fully mixed type (tank reactor) "Microscale CSTR." You can choose the method that suits your reaction conditions. Both can also be tested at our rental lab. We have over 50 types of "Microreactors" available. Please feel free to contact us when selecting a continuous reactor. 【Features】 <Microscale CSTR (Continuous Stirred Tank Reactor)> ■ Makes it easy for chemical synthesis researchers to consider scale-up ■ Continuous flow is possible even for reactions that tend to crystallize ■ Supports both small and large quantities ■ Stabilizes continuous flow reactions by connecting with microreactors ■ Enables high quality and high efficiency through continuous flow *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the new microreactor business, we are conducting research and development on "microreactors," which are cutting-edge experimental devices used in the research and development of new drugs at universities and companies, focusing on components of devices that perform chemical reactions. Microreactors are durable instruments that can handle tens of thousands of experiments with a small amount of reagents, making them economical and environmentally friendly. Additionally, they react several times faster than traditional methods of mixing reagents in beakers or test tubes, yielding high-purity results. We are expanding our business by processing microreactor products in the field of mechanical technology, aiming for product development of test pieces. 【Business Overview】 ■ Research and development of microreactors ■ Product development of test pieces *For more details, please refer to the catalog or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Mac Engineering Co., Ltd. is a company that specializes in precision parts processing and mold (die) parts processing using wire cutting, NC discharge machining, machining centers, NC lathes, and grinding machines, as well as high-hardness (ceramic high-speed steel, etc.) processing. We respond to our customers' needs with rapid and high-precision integrated manufacturing through various NC machines for complex processing and simultaneous three-axis shape processing. 【Business Activities】 ■ Precision parts processing and mold (die) parts processing ■ High-hardness (ceramic high-speed steel, etc.) processing *For more details, please refer to our catalog or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "OKM-S01/S02" is a component of a device that conducts chemical reactions and is used as experimental equipment in research and development of new drugs at universities and companies. Microreactors have durability that allows for tens of thousands of experiments with a small amount of reagents, making them an economically and environmentally friendly tool that is currently attracting attention. Compared to the traditional method of mixing reagents in beakers or test tubes, reactions occur several dozen times faster, yielding high-purity results. Additionally, experiments can be conducted in a small space, contributing to the efficiency and simplification of work. 【Features】 - Stainless steel flow path plates for easy disassembly and cleaning - Flow path plates can be customized (material, flow path shape, etc.) - Various experiments can be conducted simply by replacing the flow path plates *For more details, please refer to the catalog or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

A "microreactor" is a component of a device used for chemical reactions and is an experimental tool utilized in the research and development of new drugs at universities and companies. Microreactors are durable enough to handle tens of thousands of experiments with small amounts of reagents, making them economical and environmentally friendly tools that are currently attracting attention. Compared to traditional methods of mixing reagents in beakers or test tubes, they react dozens of times faster and yield high-purity results. Their ability to conduct experiments in a small space contributes to the efficiency and simplification of work. For more details, please contact us or refer to the catalog.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration