1~19 item / All 19 items

Displayed results

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Contact this company

Inquiry FormBefore making an inquiry

Download Profile1~19 item / All 19 items

Millimeter waves are electromagnetic waves used in automotive radar and 5G smartphones. The compact CT scanner 'VisibleSense,' which applies these millimeter waves, is equipped with our proprietary signal processing, enabling high-resolution non-destructive testing. (Patent pending) 【Features】 ○ Comparison with the conventional microwave non-destructive testing device 'HMW-SD1000' ・ High resolution: Approximately 10 times the horizontal resolution (from about 30mm to 3mm) ・ Miniaturization: Reduced to 1/50 in volume ratio ・ Cost reduction: Lower costs through material review ○ Measurement method (2D scan only) The sensor head is driven by an actuator to measure while transporting the workpiece. This allows for high resolution in the horizontal direction.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

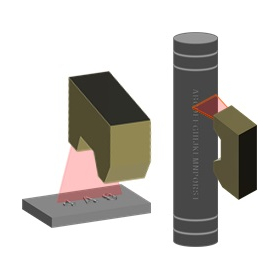

Millimeter waves are electromagnetic waves used in vehicle-mounted radar and 5G smartphones. The compact CT scanner 'VisibleSense,' which applies these millimeter waves, is equipped with our proprietary signal processing, enabling high-resolution non-destructive testing. (Patent pending) 【Features】 ○ Comparison with the conventional microwave non-destructive testing device 'HMW-SD1000' - High resolution: Approximately 10 times the horizontal resolution (from about 30mm to 3mm) - Miniaturization: Volume reduced to 1/50 - Cost reduction: Lower costs through material review ○ Measurement methods - 1D scan The sensor head is fixed while the workpiece is transported for measurement. Installation is very easy. - 2D scan The sensor head is driven by an actuator while the workpiece is transported for measurement. This allows for high horizontal resolution. - Rotational scan The sensor head is driven by an actuator during the rotation of the workpiece for measurement. This enables inspection of cylindrical products.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The microwave non-destructive testing device "HMW-SD1000" detects internal cracks in products made of resin, plastic, ceramics, and rubber. Microwaves have the property of penetrating materials, and when foreign objects or cracks exist within the material, reflection and attenuation occur. This product utilizes this phenomenon to measure and inspect the internal condition of materials in a non-contact and non-destructive manner. 【Features】 ○ Non-destructive and non-contact internal inspection possible → Microwaves penetrate the object being inspected → Internal inspection can be conducted non-destructively and non-contact ○ Not affected by the color of the object being inspected → The penetration characteristics of microwaves into materials are not influenced by the color of the object being inspected → Measurement is possible even for opaque objects ○ Automatic defect determination → By simply setting the condition parameters of the object being measured, it automatically determines the presence or absence of defects according to the application.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is a non-contact density measurement sensor using microwaves. Microwaves are electromagnetic waves with frequencies ranging from 3 to 30 GHz, characterized by strong directivity and the ability to penetrate materials. When passing through a material, a phase change occurs depending on the physical properties of that material. Utilizing this characteristic, we have developed a sensor that measures the density and mass of objects non-contactly. The object to be inspected is passed through the opening in the center of the sensor, and the phase of the microwaves corresponding to its physical properties is measured. In areas where the density or mass differs, a change in phase occurs. We capture this phase change to perform measurements. Potential applications include measuring the density and mass of granular products such as supplements, and adapting to defect inspection of extruded products (such as tubes). If you have products that undergo destructive sampling tests, please feel free to consult us first. 【Features】 ■ Non-destructive, non-contact density measurement ■ High-speed processing with 1,000 points per minute sampling

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Conventional ultrasonic testing required the probe to be in contact with some medium, such as gel or water. This device adopts the air-coupled ultrasonic method, allowing measurements to be taken non-contact in the air. 【Features】 ○ Internal inspection possible without contact and non-destructive ○ By moving a single-axis robot, measurements can be taken over a range of 150x100mm ○ Measurement results are displayed as a color contour map of transmission intensity distribution, making defects immediately apparent. ◎ Free evaluation tests are available. Please contact us for more details.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is a sensor that measures distortion using a uniquely developed MR method (Mesh Reflection). It projects slit illumination onto the measurement target and calculates curvature from the amount of distortion in the illumination. This method allows for high-precision measurement compared to pattern projection-type 3D measurement devices, as it amplifies distortion using the principle of optical leverage. 【AI that finds "something different"】 We have now made it possible to add AI judgment functionality. This AI learns the range of acceptable data from a small amount of OK data and determines anything outside the learned range as NG. Generally, AI needs to learn both OK and NG data. However, in factory production lines, the occurrence of NG is infrequent, and it takes time to accumulate sufficient NG data. On the other hand, our AI can learn with just a small amount of OK data, allowing for immediate operation right after the equipment is introduced. Additionally, as it operates for a while, NG data will accumulate. Our AI model is also equipped to learn from this NG data, enabling further improvements in detection accuracy.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

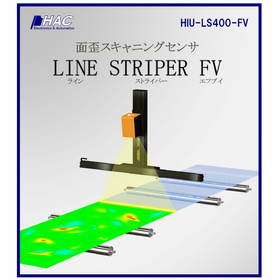

The surface distortion scanning sensor "LINE STRIPER FV" can measure minute distortions in film with high precision in-line! Using our uniquely developed MR method (Mesh Reflection), we measure distortion by projecting slit lighting onto the target object and calculating curvature from the amount of distortion in the lighting. This method amplifies distortion using the principle of optical leverage, as used in AFM (Atomic Force Microscopy), allowing for more precise measurements compared to pattern projection type 3D measurement devices. 【Features】 ■ High Sensitivity Capable of measuring minute distortions of several micrometers that are difficult to measure with conventional 3D measurement devices. ■ Wide Range Continuous in-line measurement over a wide area of 400mm. ■ Visualization Measurement results are displayed as curvature color contour maps, making minute distortion areas immediately clear! *For more details, please refer to the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Visual inspection requires skilled techniques, and there is a shortage of successors as it is difficult to train people. Inspecting large area panels takes time, so we need a system that can perform inspections quickly." "In such cases, the new product, the high-speed surface distortion scanning sensor LINE STRIPER CX, can realize an automated inspection system." "The LINE STRIPER CX has achieved a speed increase of 50 times compared to the conventional LINE STRIPER and can handle measurements at a pitch of 1mm up to a maximum of 1000mm/s." "Additionally, by adopting a new coaxial optical system, it has become more resistant to the effects of distance fluctuations caused by vibrations. Furthermore, it is equipped with a vibration suppression filter function that can also mitigate the effects of lateral vibrations." "By leveraging the 'high speed' and 'vibration resistance' of the LINE STRIPER CX and combining it with robots, high-speed surface distortion inspections are possible.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The micro surface roughness detection device "Sphirna" HIU-SP800 detects minute irregularities that are difficult to detect with conventional technology using the newly developed PH method (Pixel Histogram). Utilizing the principle of light leverage, it enables high-precision measurement compared to pattern projection type 3D measurement devices. For more details, please download the catalog or contact us. 【Features】 ○ Detects micro irregularities of Φ1mm or larger. ○ Detection results can be overlaid with images of the object, making the detection position clear at a glance. ○ Capable of measuring the tilt of the object's surface.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The micro surface roughness detection device "Sphirna" HIU-SP800 detects minute irregularities that are difficult to detect with conventional technology using a newly developed PH method (Pixel Histogram). Utilizing the principle of light leverage, it allows for high-precision measurement compared to pattern projection type 3D measurement devices. Furthermore, it employs a collaborative robot for multi-joint operations, enabling inspection alongside operators. By adopting this device, the inspection process can be automated, reducing costs while achieving higher quality and reliability. For more details, please download the catalog or contact us. 【Features】 ○ Detects micro irregularities of 1mm or more. ○ Detection results can be overlaid with images of the object, making the detection position clear at a glance. ○ Measurement of the tilt of the object's surface is also possible.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is a proposal case that achieves productivity improvement and labor reduction by automating a series of processes in the shipping and packing operations at the factory, from cardboard manufacturing, product picking, and packing to label application and sorting and stacking of cardboard. By combining robots, vision systems, and barcode readers, significant efficiency gains can be realized through optimal control. The current process requires a lot of manual labor, and there have been instances of sorting errors and the heavy labor of transporting packed cardboard boxes. Each line has three operators stationed to perform all tasks from cardboard assembly to stacking on shipping pallets manually, which occasionally leads to human errors. By automating this series of tasks, we can minimize the human involvement until shipping and reduce human errors. Furthermore, we can also build a data management system that can comprehensively manage everything from receiving to traceability, production, and shipping. We will provide an initial proposal for such automation within two weeks of receiving your inquiry.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We have developed a new processing device that utilizes robots and offers high degrees of freedom. As an application example, we introduce an automatic wire processing device. The robot uses manual tools that people typically use, and it automatically performs a series of tasks involved in processing wires, which are frequently used in control panel assembly, including: pulling out wires, cutting, inserting marker tubes, stripping insulation, and crimping. The robot is equipped with a camera that allows it to track variations in the position and shape of the wires. Since the device is composed of manual tools and robots, it can accommodate tool changes and customization of work content, allowing for various applications tailored to customer needs. **Features** - Freedom of customization through cooperative work of two industrial robots - Tracking capability of the workpiece through a combination of a fixed camera and a robot-mounted camera

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is an automatic inspection system that embodies the customer's desire for a compact device capable of conducting a full inspection of multiple inspection items that were previously performed manually, quickly and with simple operations. We adopted an indexing method where the workpiece is set on a rotary table and progresses through each inspection process. By setting the workpiece on a rotary indexing table and advancing through the processes, we minimized the picking of workpieces and achieved high-speed transfer to subsequent processes, while keeping the device size compact. The operability is designed so that after setting the workpiece, inspection can be started simply by blocking the sensor, creating a user-friendly interface for operators. The process that previously required multiple operators to perform several inspection items is now streamlined to just one operator setting the workpiece, contributing to cost reduction. Since inspection errors are eliminated regardless of operator fatigue or skill level, quality is guaranteed through full inspection, leading to improved evaluations from clients and increased sales. Additionally, the ability to conduct high-speed inspections at 1,200 units per hour has contributed to increased productivity and improved profitability. The automatic visual inspection device for micro electronic parts, born from these customer requests, can be viewed in the video below.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Surface Distortion Scanning Sensor STRIPER" from Hachiko Automation Co., Ltd. calculates curvature from the amount of change (displacement) in the stripe pattern and measures/evaluates the distortion of the object's surface. Why "curvature" instead of "displacement"? When trying to evaluate micro-distortion of a few micrometers as "displacement," it becomes buried within the displacement of the measurement surface, making it difficult to distinguish and extract the distorted areas. When evaluating micro-distortion as "curvature," the gentle changes and slopes of the measurement surface result in a large curvature radius, making the curvature almost "0," while the distorted areas have a small curvature radius, leading to significant changes in curvature that are easy to distinguish. [Contents] ■ What is curvature? ■ Advantages For more details, please refer to the catalog or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

During the painting process of the product, there are rare occasions when the surface of the paint exhibits strong orange peel, resulting in appearance defects, so we would like to evaluate the orange peel in real-time during painting. In such cases, the surface distortion scanning sensor 'SPHYRNA' can be applied to evaluate the 'orange peel.' The phenomenon where the paint surface becomes uneven like the surface of an orange is referred to as 'orange peel.' The surface distortion scanning sensor 'SPHYRNA' inspects the minute unevenness of the object's surface, and by utilizing the 'tilt' data generated during the measurement process, it is possible to evaluate the degree of orange peel.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

For example, if you want to inspect products with textured patterns like fiber sheets (geometric patterns) for scratches or foreign substances, even if you take pictures of the defective areas with a general visible light camera, the defects can be buried within the complex texture patterns, making it difficult to extract just the defects. Additionally, defects such as bubbles that occur inside the product cannot be seen with a visible light camera because they are internal. In such cases, by using a camera with a special imaging method, it is possible to visualize defects buried within patterns that were previously not visible and defects inside the product.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We propose a reading system for cast characters, mold characters, and engraved characters using a 2D laser displacement meter. 【Current Situation】 The embossed characters, such as part numbers on cast products, are the same color as the background, and there may be protrusions around the characters or the characters may be engraved on curved surfaces, making it difficult to cut out the characters. Standard optical systems cannot read these characters. 【Proposal】 "Embossed Character Recognition System Using 2D Laser Displacement Meter" By stably extracting embossed characters through 3D measurement that traces the surface shape of the object, we achieve a high character reading rate. Additionally, it supports inline measurement without contact. For more details, please refer to the catalog or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company assists customers in the FA and manufacturing industries with various challenges by developing unique production line control systems, air conditioning and heat source control systems, and inspection and measurement devices. We excel at listening to our customers' concerns and requests in detail and developing custom systems tailored to their specific needs. This time, we have solved the issue of recognizing embossed characters created by stamping and engraving! 【Challenge】 ■ Since labels for barcodes and part numbers cannot be affixed, we created part number codes using a stamping machine, but there is no system to read embossed characters... ■ We want a non-contact, stationary device for use on the manufacturing line... 【Solution】 ■ The issue is resolved by combining "bright field illumination" with an "embossed character reading algorithm." *For more details, please refer to the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This device is an automatic wire processing machine that combines commercially available devices. Originally, it consists of two types of commercially available devices, the "mark tube printer" and the "wire cutter," which are from different manufacturers. By automating the transfer section of the mark tube, it operates like a single "automatic wire processing machine." Although there is only a slight clearance between the mark tube and the wire, we have achieved the automation of delicate tasks by utilizing our control technology. With the operation of the automatic wire processing machine, operators can engage in other higher value-added tasks, and since the automatic device works continuously even at night, work efficiency is significantly improved.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration