1~38 item / All 38 items

Displayed results

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Contact this company

Contact Us OnlineBefore making an inquiry

Download PDF1~38 item / All 38 items

【STRAX】 is a grinding stone, grinding wheel, and diamond/CBN wheel (resin grinding stone). It is used for grinding hardened steel and dry/wet grinding of cemented carbide, among other applications, with a rich lineup of 11 types, ranging from heavy grinding to mirror finishing. Along with the product catalog, we will also provide you with a document on the "Fundamentals of Diamond/CBN Wheels"! Additionally, we accept test processing and test cutting with your workpieces! 【Features】 ■ A rich lineup of 11 types ■ From heavy grinding to mirror finishing ■ The bonding agent is only resin bond *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"BSD" is a standard specification diamond/CBN wheel (grinding wheel resin wheel). It is used for grinding hardened steel, dry and wet grinding of cemented carbide, flat grinding, cylindrical grinding, and also in tool grinding machines (for processing cemented carbide tools). This is a versatile type (general grinding). 【Features】 ■ Standard specification ■ Versatile type (general grinding) *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

STRAX "BK" is a diamond/CBN wheel grinding stone (resin grinding stone) that is effective for heavy grinding where shape retention is required. It employs a newly developed reinforced bond that excels in heat resistance, tensile strength, and elasticity. Shape retention has achieved double that of conventional products (compared to our company), realizing long life, high cutting, and high feed processing. 【Features】 ■ Uses a newly developed reinforced bond that excels in heat resistance, tensile strength, and elasticity ■ Achieves shape retention that is double that of conventional products (compared to our company) ■ Realizes long life, high cutting, and high feed processing *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "BT wheel" is a resin wheel (grinding wheel, resin grinding wheel) for CNC tool grinding. With the newly developed "BT bond," it achieves ideal grinding with minimal grinding resistance while maintaining shape. It can be used for machining cutting tools such as carbide end mills and ball end mills on CNC tool grinders, enabling high-speed feed (twice that of conventional methods) for flute groove processing. 【Features of BT Bond】 ■ Superior shape retention and lubrication compared to conventional bonds ■ Suitable for high-load grinding ■ Improved surface roughness due to being a resin bond ■ Compatible with oil-based grinding lubricants ■ Grinding wheel shapes and sizes can be customized (please consult us) *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "NB wheel" is a diamond/CBN wheel (grinding wheel resin wheel) suitable for internal grinding. It has low grinding load and is designed to be resistant to clogging. The wheel shaft can be selected from carbide or iron-based materials. Wheels without shafts can also be manufactured. 【Features】 ■ Suitable for internal grinding ■ Low grinding load and designed to be resistant to clogging ■ Wheel shaft can be selected from carbide or iron-based materials ■ Wheels without shafts can also be manufactured ■ Manufacturing range φ6 to 50 (please consult for sizes below φ6) *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "BLX2 wheel" is a diamond/CBN wheel (grinding wheel, resin wheel) effective for general-purpose grinding machines (tool grinders and cylindrical grinders) without an inverter. Compared to conventional products, truing and dressing are easier (without an inverter). It can also be used for dry grinding of cemented carbide, has strong self-sharpening properties, and high durability. 【Features】 ■ Effective for general-purpose grinding machines (tool grinders and cylindrical grinders) without an inverter ■ Easier truing and dressing compared to conventional products (without an inverter) ■ Usable for dry grinding of cemented carbide ■ Strong self-sharpening properties and high durability *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "ZERO Series" is a diamond/CBN wheel (grinding wheel, resin wheel) suitable for mirror grinding tailored to the workpiece material. It features a non-porous type bond that reduces scratch marks. We offer a lineup including "ZERO-1" for mirror finishing of SUS materials and cemented carbide (brittle materials), as well as "ZERO-2" for mirror finishing of hardened steel and cemented carbide. 【Features】 ■ Ideal for mirror grinding (from #1200) tailored to the workpiece material ■ Non-porous type bond ■ Reduction of scratch marks *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "BBM3 wheel" is a diamond/CBN wheel (grinding wheel, resin wheel) that experiences less shape distortion than resin bonds and allows for softer grinding than metal bonds. It enables truing and dressing similar to resin bonds. It is suitable for flat groove processing, cylindrical contouring, and vertical surface grinding. 【Features】 ■ Less shape distortion than resin bonds ■ Softer grinding than metal bonds ■ Higher feed rates compared to resin bonds ■ Truing and dressing possible similar to resin bonds *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "ABH Series" consists of diamond/CBN wheels (grinding stones, resin grinding stones) for grinding difficult-to-grind materials (such as SUS series and pre-hardened steel). It reduces grinding heat and friction resistance of the grinding edge. We offer two types: "ABH-S" for rough grinding and "ABH-M" for mirror grinding. 【Features】 ■ For grinding difficult-to-grind materials (such as SUS series and pre-hardened steel) ■ Reduces grinding heat and friction resistance of the grinding edge ■ Two types available in the lineup *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "AGW Series" is a shape-focused type of diamond/CBN wheel (grinding wheel resin wheel). It maintains cutting performance and wheel shape for hard alloys, glass-based materials, and more. We offer products such as "AGW-W" for grinding hard alloys and glass-based materials, and "AGW-S" for grinding iron-based materials. 【Features】 ■ Contouring processing (shape-focused type) ■ Maintains cutting performance and wheel shape for hard alloys, glass-based materials, and more ■ Three types of lineup available *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "BVK Series" is a high-cutting type diamond/CBN wheel (grinding wheel resin wheel). It maintains cutting performance while sustaining high cutting depth. We offer a lineup including "BVK-WS" for simultaneous heavy grinding of cemented carbide and hardened steel, as well as "BVK-S" for heavy grinding of hardened steel. 【Features】 ■ For heavy grinding (high-cutting type) ■ Maintains cutting performance while sustaining high cutting depth ■ Available in four types *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company handles the grinding tool CBN wheel (grinding stone resin wheel) 'STRAX VE wheel'. This product enables high efficiency in side and flat grinding with a single chuck, and it is possible to adopt slit grooves on the side of the abrasive layer. It allows for cooling at the processing point and the discharge of grinding chips, which can reduce grinding resistance. It is effective for the uneven grooves and corner rounding of molds. 【Features】 ■ Reduction of processes and shortening of processing time ■ High efficiency in side and flat grinding with a single chuck ■ Cooling at the processing point and discharge of grinding chips ■ Effective for uneven grooves and corner rounding of molds *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We handle the CBN grinding tool wheel (grinding stone resin wheel) 'STRAX VER wheel'. This product reduces grinding load due to the knife-edge effect of the spiral slit grooves on the outer circumference and the reduction of surface pressure. It is effective in reducing warping during thin plate surface grinding, as well as in cylindrical grinding, particularly in plunge cutting. Additionally, we also offer the outer circumference straight groove "VES wheel." 【Features】 ■ Reduces grinding load ■ Increases efficiency in thin material grinding ■ Effective in reducing warping during thin plate surface grinding ■ Effective in cylindrical grinding, especially in plunge cutting *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This product is a recommended chemical type of water-soluble grinding oil for STRAX grinding wheels (grinding wheels, resin grinding wheels). It can be used for carbide and hardened steel. It prevents the leaching of cobalt from carbide materials and has excellent corrosion resistance for work materials. 【Features】 - Recommended chemical type of water-soluble grinding oil for STRAX grinding wheels - Usable for carbide and hardened steel - Prevents the leaching of cobalt from carbide materials - Excellent corrosion resistance for work materials *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our coolant filtration system has a simple structure and is low-cost. It can be easily installed in the current coolant tank, and there is no need for magnetic separators or paper filters. Sludge accumulation in the tank and floating in the coolant are eliminated, significantly reducing cleaning time. There are no sludge scratches during mirror surface grinding. 【Features】 ■ Easily installable in the current coolant tank ■ No need for magnetic separators or paper filters ■ Eliminates sludge accumulation in the tank and floating in the coolant ■ No sludge scratches during mirror surface grinding *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

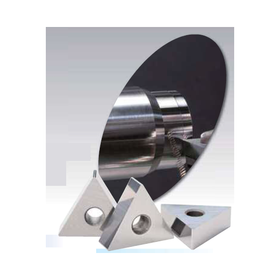

Our high-hardness steel turning and high-strength material cutting insert chip "Bertio" is suitable for hardened steel with a hardness of HRC61 or higher. Utilizing the properties of high hardness/high toughness carbide "HRA95.0," it features a sharp edge design. This results in improved finishing accuracy and wear resistance due to its sharp cutting ability. Unlike cBN inserts that require high rotation speeds, it can be used with general-purpose equipment. Additionally, compared to conventional tools, it offers improved lifespan and greater cost-effectiveness. 【Features】 ■ Suitable for hardened steel with HRC61 or higher ■ Edge shape with sharp edges ■ Improved finishing accuracy and wear resistance due to sharp cutting ability ■ Usable with general-purpose equipment compared to cBN inserts that require high rotation speeds ■ Improved lifespan and significant cost-effectiveness compared to conventional tools *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our high-hardness steel turning and high-strength material cutting insert chip "Bertio" is suitable for hardened steel with a hardness of HRC61 or higher. Utilizing the properties of high hardness/high toughness carbide "HRA95.0," it features a sharp edge design. This results in improved finishing accuracy and wear resistance due to its sharp cutting ability. Unlike cBN inserts that require high rotation speeds, it can be used with general-purpose equipment. Additionally, compared to conventional tools, its lifespan is improved, and cost-effectiveness is further anticipated. 【Features】 ■ Suitable for hardened steel with HRC61 or higher ■ Edge shape with sharp edges ■ Achieves improved finishing accuracy and wear resistance due to sharp cutting ability ■ Usable with general-purpose equipment compared to cBN inserts that require high rotation speeds ■ Improved lifespan compared to conventional tools, resulting in great cost-effectiveness *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our high-hardness steel turning and high-strength material cutting insert chip "Bertio" is suitable for hardened steel with a hardness of HRC61 or higher. Utilizing the characteristics of high hardness/high toughness carbide "HRA95.0," it features a sharp edge design. This results in improved finishing accuracy and wear resistance due to its sharp cutting performance. Unlike cBN inserts that require high rotation speeds, it can be used with general-purpose equipment. Additionally, compared to conventional tools, its lifespan is improved, leading to greater cost-effectiveness. 【Features】 ■ Suitable for hardened steel with HRC61 or higher ■ Edge shape with a sharp edge ■ Improved finishing accuracy and wear resistance due to sharp cutting performance ■ Usable with general-purpose equipment compared to cBN inserts that require high rotation speeds ■ Improved lifespan compared to conventional tools, resulting in high cost-effectiveness *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our high-hardness steel turning and high-strength material cutting insert chip "Bertio" is suitable for hardened steel with a hardness of HRC61 or higher. Utilizing the properties of high hardness/high toughness carbide "HRA95.0," it features a sharp edge design. This achieves improved finishing accuracy and wear resistance due to its sharp cutting ability. Unlike cBN inserts that require high rotation speeds, it can be used with general-purpose equipment. Additionally, compared to conventional tools, its lifespan is improved, and cost-effectiveness is further expected. 【Features】 ■ Suitable for hardened steel with HRC61 or higher ■ Edge shape with a sharp edge ■ Achieves improved finishing accuracy and wear resistance due to sharp cutting ability ■ Can be used with general-purpose equipment compared to cBN inserts that require high rotation speeds ■ Improved lifespan compared to conventional tools, resulting in great cost-effectiveness *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our high-hardness steel turning and high-strength material cutting insert chip "Bertio" is suitable for hardened steel with a hardness of HRC61 or higher. Utilizing the properties of high hardness/high toughness carbide "HRA95.0," it features a sharp edge design. This results in improved finishing accuracy and wear resistance due to its sharp cutting ability. Unlike cBN inserts that require high rotation, it can be used with general-purpose equipment. Additionally, compared to conventional tools, its lifespan is improved, leading to greater cost-effectiveness. 【Features】 ■ Suitable for hardened steel with HRC61 or higher ■ Edge shape with a sharp edge ■ Improved finishing accuracy and wear resistance due to sharp cutting ability ■ Usable with general-purpose equipment compared to cBN inserts that require high rotation ■ Improved lifespan compared to conventional tools, resulting in high cost-effectiveness *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our high-hardness steel turning and high steel cutting insert chip "Bertio" is suitable for hardened steel with HRC61 or higher. Utilizing the characteristics of high hardness/high toughness carbide "HRA95.0," it features a sharp edge design. This achieves improved finishing accuracy and wear resistance due to its sharp cutting ability. Unlike cBN inserts that require high rotation, it can be used with general-purpose equipment. Additionally, compared to conventional tools, its lifespan is extended, and cost-effectiveness is further expected. 【Features】 ■ Suitable for hardened steel with HRC61 or higher ■ Edge shape with sharp edge ■ Improved finishing accuracy and wear resistance due to sharp cutting ability ■ Usable with general-purpose equipment compared to cBN inserts that require high rotation ■ Extended lifespan compared to conventional tools, resulting in high cost-effectiveness *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our high-hardness steel turning and high steel material cutting insert chip "Bertio" is suitable for hardened steel with a hardness of HRC61 or higher. Utilizing the properties of high hardness/high toughness carbide "HRA95.0," it features a sharp edge design. This achieves improved finishing accuracy and wear resistance due to its sharp cutting performance. Unlike cBN inserts that require high rotation, it can be used with general-purpose equipment. Additionally, compared to conventional tools, its lifespan is improved, and cost-effectiveness is further expected. 【Features】 ■ Suitable for hardened steel with HRC61 or higher ■ Edge shape with a sharp edge ■ Achieves improved finishing accuracy and wear resistance due to sharp cutting performance ■ Can be used with general-purpose equipment compared to cBN inserts that require high rotation ■ Improved lifespan compared to conventional tools, offering great cost-effectiveness *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our high-hardness steel turning and high steel cutting insert chip "Bertio" is suitable for hardened steel with a hardness of HRC61 or higher. Utilizing the properties of high hardness/high toughness carbide "HRA95.0," it features a sharp edge design. This achieves improved finishing accuracy and wear resistance due to its sharp cutting performance. Unlike cBN inserts that require high rotation, it can be used with general-purpose equipment. Additionally, compared to conventional tools, its lifespan is improved, leading to greater cost-effectiveness. 【Features】 ■ Suitable for hardened steel with HRC61 or higher ■ Edge shape with a sharp edge ■ Achieves improved finishing accuracy and wear resistance due to sharp cutting performance ■ Can be used with general-purpose equipment, unlike cBN inserts that require high rotation ■ Improved lifespan compared to conventional tools, resulting in high cost-effectiveness *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our high-hardness steel turning and high steel cutting insert chip "Bertio" is suitable for hardened steel with HRC61 or higher. Utilizing the characteristics of high hardness/high toughness carbide "HRA95.0," it features a sharp edge design. This achieves improved finishing accuracy and wear resistance due to its sharp cutting ability. Unlike cBN inserts that require high rotation, it can be used with general-purpose equipment. Additionally, compared to conventional tools, its lifespan is improved, and cost-effectiveness is further expected. 【Features】 ■ Suitable for hardened steel with HRC61 or higher ■ Edge shape with sharp edges ■ Achieves improved finishing accuracy and wear resistance due to sharp cutting ability ■ Can be used with general-purpose equipment compared to cBN inserts that require high rotation ■ Improved lifespan compared to conventional tools, resulting in great cost-effectiveness *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This product can be used for internal grinding and tool grinding, has low grinding load, and is less prone to clogging. The electroplated layer is resistant to peeling, which increases its lifespan. Abrasive grains can be selected from diamond/CBN. Wheel shafts and bases can be chosen from carbide or iron-based materials. Production lots can be accepted from one piece. Please consult us regarding wheel shapes. 【Features】 ■ Usable for internal grinding and tool grinding ■ Low grinding load and less prone to clogging ■ Electroplated layer is resistant to peeling, increasing lifespan ■ Abrasive grains can be selected from diamond/CBN ■ Wheel shafts and bases can be selected from carbide or iron-based materials *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We offer PCD insert chip regrinding. We can also accommodate changes to the nose radius, and minor wear or chipping can be repaired for reuse. Please feel free to consult us regarding compatible sizes. 【Features】 ■ Accommodates changes to the nose radius ■ Minor wear or chipping can be repaired for reuse *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We offer special race centers (M・T No.3 to 6). You can freely set the size of the carbide material and the carbide portion, and by finishing the tip to a mirror surface, we reduce friction resistance and minimize wear on the sliding parts. If you have any centers that have become unusable due to chipping or friction, we also provide repair processing. Please feel free to consult with us. 【Features】 ■ Freely adjustable size of carbide material and carbide portion ■ Reduces friction resistance and minimizes friction in sliding parts *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"VELTIO" is a turning insert for high-hardness steel that has developed a wear-resistant tool material with a hardness of "HRA95" by adding carbon nanotubes. It is suitable for hardened steel of HRC61 or higher. The new catalog includes two new model numbers, "DCMT-" and "VCMW-", bringing the total to nine different model numbers! 【Features】 ■ Developed a wear-resistant tool material with a hardness of "HRA95" ■ Suitable for hardened steel of HRC61 or higher *We also accept test machining and test cutting with your workpieces. For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Truing dressing is one of the essential elements in grinding processes. The 'KTB Block' that we handle comes in three types: "KTBS," "KTBM," and "KTBL," depending on the size of the grinding wheel. It is suitable for flat grinding (rough to about #800) and can perform truing dressing with a single unit. It is used with magnetic fixation. Additionally, the "KTBM" can also perform truing on the side of the grinding wheel. 【Features】 ■ For flat grinding (rough to #800) ■ Can perform truing dressing with a single unit ■ Used with magnetic fixation ■ "KTBM" can also perform truing on the side of the grinding wheel *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Truing dressing is one of the essential elements in grinding processes. The 'KSG Turuar' that we handle comes in two types, "KSGS" and "KSGM," according to the size of the grinding wheel. It can be used with magnetic fixation, allowing truing dressing while reducing damage to the wheel during flat grinding (for mirror finish wheels). 【Features】 ■ Enables truing dressing while reducing damage to the wheel during flat grinding (for mirror finish wheels) ■ Used with magnetic fixation *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Truing dressing is one of the essential elements in grinding processing. The "KCG Turu-A" that we handle comes in two types: "KCGR" for rough processing and "KCGF" for mirror finishing. It is used for cylindrical grinding (both rough and mirror finishing) with jaws or collet chucking. Truing dressing of the grinding wheel's outer circumference and side is possible. [Features] ■ Cylindrical grinding (for rough and finishing processing) ■ Used with jaws or collet chucking ■ Truing dressing of the grinding wheel's outer circumference and side is possible *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This document summarizes the specifications of "super abrasive wheels" and "general sintered grinding wheels." It includes the "specification notation" for both "super abrasive wheels" and "general sintered grinding wheels," as well as items such as "grit," "grain size," "bonding strength," and "concentration/structure." Please make use of it. [Included Items] ■ Specification Notation ■ Abrasive Grain ■ Grain Size ■ Bonding Strength ■ Concentration/Structure ■ Bonding Agent *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This document summarizes a comparison between "CBN wheels," which are grinding wheels, and "general sintered grinding wheels." It includes various items such as the "machinability" of both "CBN wheels" and "general sintered grinding wheels," as well as "truing and dressing" and "surface roughness." Please make use of it. 【Included Items】 ■ Machinability ■ Truing and Dressing ■ Surface Roughness ■ Wheel Life ■ Price *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is an introduction to our "Mold and Carbide KMD" products. By combining our mold manufacturing technology cultivated through cold forging with our in-house developed carbide materials, we provide high-quality and long-lasting molds. Our expertise in "precision cold forging molds" and "in-house manufactured carbide materials" leads to benefits such as reduced manufacturing costs and mold expenses due to the increased lifespan of the molds. 【Features】 ■ High hardness and high toughness carbide material with carbon nanotube composition ■ Effective not only for mold applications but also for cutting tools and jigs ■ Capable of mass production through press forming *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our carbide materials are developed through repeated mold life tests on our in-house automotive parts cold forging mass production line. We have achieved a mold life improvement of 1.5 to 10 times compared to conventional (other manufacturers' carbide materials) mold life, successfully switching about 90% of our in-house carbide molds to our own carbide materials. In addition to forging, our materials are also used in glass molding molds, IC lead frame punching dies, light load drawing dies, powder molding molds, cutting tools, and more, receiving high praise from our customers. 【Products Offered】 ■ Various punch materials ■ Various die materials ■ Various jig materials ■ Various centerless round bars ■ Various plate and cutting tool materials ■ Various mass production part materials *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company handles "high-precision secondary processed parts." We perform high-precision secondary processing such as cutting and grinding on each part shaped by cold forging, using appropriate methods and equipment, and provide them to our customers as finished products. For high-precision secondary processed parts, please leave it to us. 【Features】 ■ High-precision secondary processing such as cutting and grinding is performed using appropriate methods and equipment. ■ Provided to customers as finished products. *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Katagiri Manufacturing Co., Ltd. has established advanced mass production technology that simultaneously achieves stable quality and high productivity through ongoing research and development in precision cold forging. With an advanced production system that pursues automation and labor-saving from process analysis to pre-processing, mold design and manufacturing, forming and processing, and secondary processing, we realize cost-effective product manufacturing. Furthermore, in 2002, we independently developed technology for small-diameter precision cold forging, enabling the production of more precise components. [Features] - Established advanced mass production technology that simultaneously achieves stable quality and high productivity - Realized cost-effective product manufacturing - Enabled the production of more precise components *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Katagiri Manufacturing Co., Ltd. is a comprehensive forging manufacturer that handles everything from mold materials to molds, forging, and finished products. We utilize our expertise to manufacture and sell carbide materials, completed molds, and our own brand of diamond/CBN wheels called "STRAX." [Business Activities] - Precision cold forging and high-precision secondary processing - Manufacturing and sales of super abrasive tools, molds, and carbide products For more details, please contact us or download our catalog.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration