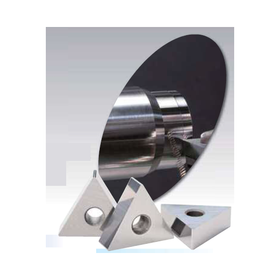

Turning tools for high hardness steel and insert chips for high steel material cutting 'VELTIO'

Developed in-house ultra-hard material (hardness HRA95.0) for wear-resistant tool materials! Suitable for hardened steel with HRC61 or higher!

"VELTIO" is a turning insert for high-hardness steel that has developed a wear-resistant tool material with a hardness of "HRA95" by adding carbon nanotubes. It is suitable for hardened steel of HRC61 or higher. The new catalog includes two new model numbers, "DCMT-" and "VCMW-", bringing the total to nine different model numbers! 【Features】 ■ Developed a wear-resistant tool material with a hardness of "HRA95" ■ Suitable for hardened steel of HRC61 or higher *We also accept test machining and test cutting with your workpieces. For more details, please refer to the PDF document or feel free to contact us.

Inquire About This Product

basic information

【TNGA160402/04 Specifications】 ■Shape: Triangle ■Nose R ・0.2 ・0.4 ■Application: End face and outer diameter processing ■Number of corners: 6 *For more details, please refer to the PDF document or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

■Other Uses Insert Chips For Cutting High Steel Materials For Cutting Hardened Steel Internal Diameter Cutting External Diameter Cutting End Face Cutting CBN Chips *For more details, please refer to the PDF document or feel free to contact us.

catalog(1)

Download All CatalogsCompany information

Katagiri Manufacturing Co., Ltd. introduced cold forging technology for the first time in the Tohoku region in 1966. Since then, as a pioneer in precision cold forging, the company has continued research and development, establishing advanced mass production techniques that achieve both stable quality and high productivity. Currently, the company realizes cost-effective product manufacturing through an advanced production system that pursues automation and labor-saving from process analysis to pre-processing, mold design and manufacturing, forming and processing, and secondary processing. Furthermore, it has independently developed world-first technology in small-diameter precision cold forging, enabling the production of more precise components. Additionally, recognizing the necessity for precision mold processing, the company has developed super abrasive tools in-house. Under the "STRAX" brand, it manufactures and sells these tools nationwide, and has also succeeded in developing carbide materials to improve mold lifespan, along with manufacturing and selling various molds that utilize these materials. Test processing and test cutting services are also available.