91~115 item / All 115 items

Displayed results

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Contact this company

Inquiry FormBefore making an inquiry

Download Profile91~115 item / All 115 items

In sheet metal work, effectively utilizing standard products available in the market can lead to reduced lead times and cost savings. When using pipes that are not standard, the processes of "material purchase" → "bending with a three-roll machine" → "welding" → "stress relief" → "finishing" are required, so it is necessary to make selections based on the balance of cost and functionality. For pipe shapes, selecting from standard products available in the market and reflecting that in the design can lead to cost reductions. Since the standards for SS and SUS materials differ in the market, it is helpful to consider those when designing. [Features] ■ For pipe shapes, designing after confirming the standards for materials such as steel, SUS, and aluminum will impact lead times and costs. ■ Selecting from standard products available in the market and reflecting that in the design. *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

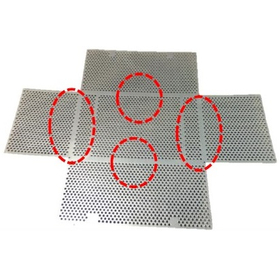

When bending pre-made punch metal, dimensional accuracy tends to be rough, leading to variability in bending dimensions and larger tolerances. If dimensional accuracy is absolutely necessary and there are no design or engineering issues, using V-bending can eliminate holes in the bending interference areas, resulting in bending precision that matches the level of standard products. While this requires custom parts rather than off-the-shelf products, considering the accuracy and yield, significant overall cost reductions can be achieved. 【Features】 ■ V-bending ■ Elimination of holes in bending interference areas ■ Bending precision matches the level of standard products ■ Significant cost reduction *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In precision sheet metal and can manufacturing design, being able to break down the necessary appearance surfaces to the level of individual drawings can provide significant benefits in terms of quality stability and cost reduction. Even if there are no indications of exposed surfaces in the drawings, a skilled processor can often infer the surface details, but it can be unclear without explicit instructions. By specifying the appearance surfaces that require buffing in the drawings, the necessary areas become clear, allowing the processing side to reduce considerations for areas other than the required parts, which leads to improved quality and cost reduction. [Features] - Clearly defines the necessary areas by specifying the appearance surfaces that require buffing in the drawings. - Allows the processing side to reduce considerations for areas other than the required parts. - Leads to improved quality and cost reduction. *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In precision sheet metal work, when bending a plate with holes, it is necessary to maintain a sufficient distance between the bending position and the holes. If it is absolutely impossible to maintain this distance, bending should be performed before hole processing. This will increase the man-hours, so by designing with such processing in mind, it can lead to cost reduction. By ensuring the distance between the bending position and the holes for each plate thickness, we can suppress the occurrence of hole deformation, thereby achieving cost reduction. [Features] ■ By ensuring the distance between the bending position and the holes for each plate thickness, we can suppress the occurrence of hole deformation, thereby achieving cost reduction. *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In precision sheet metal and can manufacturing design, the height of the bend flange is one of the important cost factors. Parts where the height of the bend flange is less than five times the sheet thickness make V-bending difficult. Extending the flange length for bending and then shortening it through subsequent machining increases labor hours and leads to higher costs. By extending the flange length to about five times, the product shape can be achieved through V-bending, eliminating the need for post-processing and enabling significant cost reduction. 【Features】 - By extending the flange length to about five times, the product shape can be achieved through V-bending. - Significant cost reduction is possible without the need for post-processing. *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

When cutting the outer shape of sheet metal or processing holes, processing allowances and gripping allowances are necessary. Processing products from materials without a support width can lead to cutting defects and dimensional issues. By ensuring that the outer perimeter of the product has a support width of at least twice the plate thickness or about 10mm, the burden on the processor is reduced. Having sufficient material reduces the burden during the creation of processing programs and actual processing, leading to cost reductions. Additionally, having the same perspective on yield with the processing department stabilizes the calculated costs. **Features** - Reduces the burden on processors by being mindful of support width. - If there is sufficient material, it decreases the burden during processing program creation and actual processing. - Having the same perspective on yield with the processing department stabilizes calculated costs. *For more details, please refer to the PDF document or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the case of products that can be grouped by lot size, being mindful of the dimensions can lead to significant improvements in yield and cost reduction. It is important to design with material widths of 3 shaku, 4 shaku, 5 shaku, and standard widths in mind. It is essential to convey the designer's intentions to the production side. 【Features】 ■ Significant improvements in yield and cost reduction are possible by being mindful of dimensions ■ Designing with material widths of 3 shaku, 4 shaku, 5 shaku, and standard widths in mind is important ■ It is essential to convey the designer's intentions to the production side *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In product design, it is important to clarify whether to incorporate press forming or to proceed with sheet metal processing, thereby indicating the designer's stance on the method. Products with deep forming shapes or those that include irregular shapes are processed using the press method. When choosing sheet metal processing, parts design is carried out with an awareness of a forming height of 5mm or less. For products with many flat surfaces and linear bending points, designing with a focus on sheet metal fabrication conveys the manufacturing stance to the production side. By considering factors such as lot size and essential shapes, indicating the direction of either press or sheet metal production leads to cost reduction. **Features** - Clearly distinguish between press processing and sheet metal processing in design. - Suggest whether mold production is anticipated on the manufacturing side, which contributes to cost reduction. *For more details, please refer to the PDF document or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In product design, the manufacturing of parts with a drawn shape requires the preparation of molds for each part, resulting in initial costs. Although the product shapes are different, if the product height and R shapes are similar, it may be possible to fit them into a single drawn shape depending on the arrangement. For products like brackets that have left/right variations, it is often possible to accommodate two identical shapes together. Even with slight differences in shape, there is ample room for consideration, and it is possible to reduce initial costs. By anticipating this during the design phase and creating drawings accordingly, cost reduction can be achieved. [Features] - The product height and R shapes are similar, and depending on the arrangement, they can be accommodated in a single drawn shape. - It is often possible to accommodate two identical shapes together. - Designing with the concept of two parts per mold in mind is important. *For more details, please refer to the PDF materials or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

When production lots are consolidated, considering a method transition to pressing can lead to cost reduction. In the case of welded pipe cut products and sheet materials, the cost tends to be high due to the welded structure, and processing of burrs and edges is also necessary. Transitioning to pressing requires an initial investment, but it can dramatically lower the unit price and also improve the appearance. Considering quantity and continuity, it is worth exploring method transitions as one of the options depending on the situation. 【Features】 ■ Consider method transition to pressing when production lots are consolidated ■ Can dramatically lower the unit price ■ Improves appearance *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The decisive difference between nut welding and burring (screw) processing is whether process integration is possible. "Nut welding" is a separate process using a different machine, while "burring + screw processing" can be integrated with blank processing, leading to cost reduction. When connecting parts where strength is not required, switching to burring processing allows for a reduction in the number of components, a reduction in man-hours, and the possibility of process integration using laser combination machines. Additionally, it can reduce the distortion that occurs during welding, contributing to the stabilization of quality. 【Features】 ■ Burring + screw processing can be integrated with blank processing ■ Reduction in the number of components and man-hours leads to cost reduction ■ Switching from welding brings significant benefits *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In precision sheet metal and can manufacturing, if there are no functional issues, the process design from hole processing to bending processing on the sheet is the most effective way to reduce costs. Switching to bending processing after hole and contour cutting with lasers or NCT allows for the production of products using the same machine, leading to cost reduction. 【Features】 ■ The process design from hole processing to bending processing on the sheet is the most effective way to reduce costs. ■ Switch to bending processing after hole and contour cutting with lasers or NCT. ■ It is possible to proceed with product manufacturing using the same machine. *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In precision sheet metal and can manufacturing design, the processing man-hours can vary significantly depending on whether the focus is on exterior quality or if functionality is maintained without issues. By collaborating with sheet metal manufacturers that own laser-punch combination machines and considering value analysis (VA) and value engineering (VE) for forming processes, cost reductions can be achieved. If there are no issues with the appearance, forming processes such as countersinks and rivet holes can be processed with a combination machine in mind, allowing for cost savings. 【Features】 ■ Consider VA and VE for forming processes ■ Adopt countersinks and rivet holes that can be formed using combination machine molds ■ Significant cost reduction and quality improvement can be expected *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In products that require strength, "welding at two opposing sides" is an effective joining method. However, in the case of thin sheets or products that do not require strength, it can lead to distortion and increased costs. For products that do not require strength, switching to "spot weld nut welding" will require management of welding conditions, but it can reduce the welding labor time to less than half, leading to cost reduction. Additionally, aligning the hole and nut concentrically can be achieved with a weld nut guide (pilot), eliminating the need for dedicated jigs. 【Features】 ■ For nut welding on thin sheets or products that do not require strength, switching to spot weld nut welding allows for distortion reduction and labor time savings. ■ Since concentric alignment of the hole and nut can be achieved with a weld nut guide, dedicated jigs are not necessary. *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

When considering cost reduction in sheet metal work, it is essential to review the welding method first. For example, switching from TIG welding to spot welding can reduce distortion and shorten work time. However, it is necessary to design the parts with welding allowances, as the current shape may not be suitable for switching to spot welding. 【Features】 ■ The choice of welding method significantly affects costs. ■ Switching to spot welding reduces distortion. ■ It is possible to reduce work time. *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In processing, when preventing areas with gaps, using a bent plate that has undergone burring processing instead of a machined product allows for cost reduction. By adopting such components, installation can be done with spot welding instead of TIG welding, minimizing distortion. 【Features】 ■ Sheet metal processing takes less time than machining ■ Cost can be reduced compared to machined products ■ Distortion caused by welding can also be minimized *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In precision sheet metal and machining, there are often specifications for dimensional accuracy and geometric tolerances that exceed what is necessary, which affects costs. If surface roughness is specified, machining is the only option; however, if surface roughness is not required, prompting the manufacturing side to consider alternative processing methods through comments can allow for a switch from machining to laser processing, leading to cost reductions. [Features] ■ Specifications for dimensional accuracy and geometric tolerances that exceed what is necessary affect costs. ■ If surface roughness is not required, prompting the manufacturing side to consider alternative processing methods through comments can allow for a switch to laser processing. *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

I would like to introduce "Cost Reduction through Reinforcement Rib Implementation (Method Transition)." If the purpose of ribs and beads is merely for reinforcement, the dimensions and shapes can be entrusted to the manufacturing side, allowing for the "as-built shape" to be indicated on the drawings, which can help reduce initial costs. This is particularly effective for small lot products and prototypes. If limited to one or two locations, it is possible to manufacture reinforcement ribs during brake bending, resulting in cost reduction benefits. [Features] - By indicating the as-built shape on the drawings for small lots and prototype products, initial cost generation can be minimized. - The shape is derived by extending general-purpose molds. *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In product design, we will introduce a "design approach" that maintains design and functionality while improving quality and reducing costs. By incorporating points from the perspective of the manufacturer into the design, we can expect improvements in cost and quality. [Key Points] - Confirm points to control design and functionality (direction of the process) - Selection of materials and surface treatments according to application - Selection of joining methods (welding, assembly) based on product strength - Selection of appropriate precision and fit for the product level, and utilization of geometric tolerances - Incorporation of design intentions into the drawings *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Hayano Kenko Co., Ltd., which manufactures press parts for vehicle body development and processes various industrial equipment parts, introduces the processes and flow of sheet metal work. The field of sheet metal can be broadly divided into three categories. While there are differences in required precision and applications, the basic processes for transforming a single sheet of steel into a product are as follows: 【Processes and Flow】 ■1. Method consideration and meetings ■2. Mold design ■3. Jig production ■4. Mold production ■5. Punching process *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Hayano Kenko Co., Ltd., which manufactures press parts for vehicle body development and processes various industrial equipment parts, introduces representative press, sheet metal, and cutting machines. Starting with the "Machining Center," which can process drilling and milling with numerous tools and is capable of three-dimensional shape processing, there are also the "Turret Punch Press," which performs cutting and hole processing using a combination of molds, and the "Hydraulic Press Machine," which has a high effective stroke and is used for drawing processing. 【Representative Machines (Partial)】 ■ Machining Center ■ Turret Punch Press ■ Shearing Machine ■ 3D Laser Processing Machine ■ Fiber Laser Combined Processing Machine ■ Press Brake *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

There are two main methods (approaches) for prototype sheet metal fabrication. One is "shape prototype sheet metal," where we create a unique press die (simple) for the product and focus on forming processes. The other is "precision prototype sheet metal," where we utilize general-purpose dies and machines to proceed without creating dedicated dies. [Methods] ■ Shape Prototype Sheet Metal - Mainly for automotive and agricultural press parts ■ Precision Prototype Sheet Metal - For heavy and light electrical components, machine tool parts *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Sheet metal can be broadly categorized into three areas from a processing method perspective. 1. Processing that advances as a three-dimensional shape using dedicated molds (press) is referred to as "shape prototype sheet metal." 2. Processing that advances as a two-dimensional shape while minimizing costs is called "precision prototype sheet metal." 3. Processing for general machinery and equipment covers construction and architecture, known as "general sheet metal." "Shape prototype sheet metal" and "precision prototype sheet metal" are collectively referred to as "prototype sheet metal," distinguishing them from general sheet metal. While there are many commonalities in processing methods, specialized manufacturers in the industry may face challenges in quality, cost, and equipment, so caution is necessary. Additionally, it is very important to select suppliers with the specialized fields in mind. *For more details, please refer to the PDF materials or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Sheet metal processing refers to the general term for the process of plastically deforming thin sheets at room temperature (cutting and bending) into various shapes. When an external force is applied to the material, it deforms, and depending on how the load is applied, the state of deformation can be classified into five categories: "tension," "compression," "shear," "bending," and "twisting." Among these, sheet metal primarily involves three types of deformation: "drawing (tension and compression)," "shear," and "bending." Understanding the relationship between "material properties" and "applied stress" helps to support the work processes involved in sheet metal phenomena. When considering bending and drawing processing forces, similar to calculating shear processing forces, they are derived based on tensile strength and various factors such as material length and sheet thickness. *For more details, please refer to the PDF document or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Hayano Kenko Co., Ltd. is a company that manufactures automotive prototype sheet metal, achieving high precision, short delivery times, and a variety of products. We possess the latest equipment and offer high precision NC processing at town factory costs, proposing methods tailored to our customers' needs, from 3D laser processing to handmade solutions. Manufacturers struggling with short delivery times and trading companies facing budget constraints are welcome to consult with us. 【Industry】 ■ Production of body development press parts ■ Precision prototype sheet metal ■ Processing of various industrial equipment parts *For more details, please refer to our catalog or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration