1~29 item / All 29 items

Displayed results

Filter by category

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Contact this company

Contact Us OnlineBefore making an inquiry

Download PDF1~29 item / All 29 items

Filter by category

A "atmospheric pressure plasma device" refers to a plasma device that can be generated in normal atmospheric conditions without the need for special environments such as vacuum chambers or filling with reaction gases. It is expected to have various effects for applications such as improving hydrophilicity and lipophilicity, coatings, special painting, enhancing quality in adhesion, removing organic substances that cannot be cleaned, and promoting chemical changes. 【Features】 ■ Usable in normal atmospheric pressure without the need for equipment like vacuum (reduced pressure) chambers ■ Capable of constructing a simple and space-saving system ■ Prototyping and installation on existing devices can be done on a low budget *For more details, please download the catalog or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We examined the sterilization effect of atmospheric pressure plasma on microorganisms attached to the glass surface of smartphones and will introduce the details of the microorganisms involved and the results. Microorganisms were collected from the "untreated area" and the "area irradiated with atmospheric pressure plasma" on the glass surfaces of two staff members' smartphones using cotton swabs, and cultured. We then evaluated the sterilization effect by comparing the colonies of microorganisms formed on the Petri dishes from both areas. As a result, mainly "bacteria from hands" and "bacteria from the environment" were identified, with at least three types of microorganisms observed. On the plates after plasma irradiation, the number of bacterial or yeast colonies decreased compared to the "untreated" ones. Fungi and actinobacteria were still observed after plasma irradiation. [Observed Microorganisms] ■ Bacteria or Yeast ■ Filamentous Fungi (Mold) ■ Actinobacteria *For more details, please refer to the related links or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

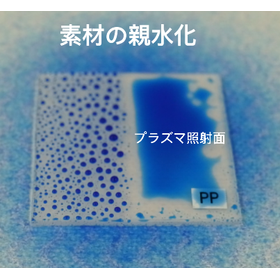

As an example of the applications of atmospheric pressure plasma devices, we tested the "hydrophilicity effect of various materials." You can observe the changes in hydrophilicity (wetting properties) of various resin materials, glass, and metals when exposed to a plasma jet. All tests were conducted under the same conditions after plasma treatment, but by changing the irradiation conditions, there are materials that can achieve even stronger effects. You can watch the actual test videos at the linked site. 【Other examples of applications for atmospheric pressure plasma devices】 ■ Hydrophilicity effect of various materials ■ End treatment test of silicone tubes ■ Effect test of atmospheric pressure plasma on liquids ■ Butt joint test of silicone rubber cords ■ Silicone rubber vs double-sided tape adhesion enhancement *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"Contact angle measurement" is a commonly used inspection method to assess the strength of atmospheric pressure plasma effects. A droplet of water is placed on the surface of the target material, and the angle at the point of contact with the material is measured. The smaller the value, the more hydrophilic (the better the affinity for water) the material is. Our company uses the Ellipse (Tangent-1) method, which analyzes the contour of the water droplet by tracing it as separate parts of two ellipses, as the standard analysis method. 【Other Analysis Methods】 ■ 1/2θ Method ■ Tangent Method ■ Young Laplace Method ■ Circle Method *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We, Aqua, are a company that responds to our customers' needs with high technical capabilities. We manufacture cleaning equipment for resin processing and LCD production, various small labor-saving devices, and cleaning equipment for semiconductor manufacturing. We handle a variety of resin processing, accommodating a wide range of materials such as polyvinyl chloride, polyethylene, polyacetal, PTFE, PEEK, ABS, polycarbonate, and Bakelite. 【Products and Services (partial)】 ■ PVC bonding and welding processing ■ Cutting processing ■ Disc brushes and roll brushes ■ PP and PVDF welded products ■ Equipment piping construction *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

For the repair and extension of the life of equipment and structures, the adhesion of coatings, adhesives, and paints is crucial. However, the presence of rust, contamination, and degraded films, as well as the properties of the material surface, can lead to issues such as "peeling" or "bubbling" after treatment. Our atmospheric pressure plasma device activates the surfaces of metals, plastics, and rubber at the nano level without using chemicals or solvents. This enhances the adhesion of adhesives and paints, improving the reliability and durability of repairs. *The effectiveness may vary depending on the condition of the surface and the material. To confirm the optimal effect for your products and treatment targets, we conduct preliminary tests. We also offer on-site testing at our lab and rental services for test equipment upon request. Please try the reliable effects of atmospheric pressure plasma at your location. Feel free to consult us as a means to extend the lifespan and assist with repairs.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Improve the 'wetting properties' of PP and PE. Solve adhesion, printing, and painting troubles with hydrophilization! Plastics such as polypropylene (PP) and polyethylene (PE) have low surface energy, making them 'difficult to wet' and 'non-adhesive' materials. This leads to issues on-site, such as printing inconsistencies, poor adhesion, and paint peeling. Our atmospheric pressure plasma device modifies the surface of materials at the nano level without the need for vacuum, contact, or chemicals, imparting hydrophilicity (ease of wetting). By significantly reducing the contact angle, we can expect improved adhesion of paints, adhesives, and inks. 'We want to see the effects on actual resins' or 'We want to confirm if it can be used in our internal processes.' To verify the optimal effects for your products and processing targets, we conduct preliminary tests. Depending on your needs, we also offer on-site testing at our lab and rental services for test equipment. Please confirm the reliable effects of atmospheric pressure plasma at your location. -- The evolution into a new world begins from the day you contact us -- *The effectiveness and durability of hydrophilization may vary depending on the manufacturer, grade of the material, and the presence of additives.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

By using low-temperature plasma (below 60°C) generated under atmospheric pressure, you can easily achieve effects such as hydrophilization, surface modification, material activation, and functional group decoration without the use of chemical solutions or special processes. Space-saving design. With nitrogen gas and an AC 100V power supply, you can easily conduct experiments in a lab that tends to have many items, all within a small space. We offer a wide range of products to accommodate various applications. To confirm the optimal effects for your products and processing targets, we conduct preliminary tests. Depending on your needs, we can also provide on-site testing at our lab or rental services for testing equipment. Please verify the reliable effects of atmospheric pressure plasma at your location. The evolution into a new world begins from the day you contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

To maximize the performance of coatings, surface preparation (surface modification) is essential. Our atmospheric pressure plasma equipment modifies the surface of materials in a non-contact manner at atmospheric pressure, significantly improving the adhesion, durability, and uniformity of coatings. It accommodates a wide range of materials, including resins, metals, glass, and ceramics, and realizes surface preparation that allows coatings to exhibit their inherent performance without the use of chemicals and in a non-contact manner. *The effectiveness may vary depending on the compatibility with the material and coating. To confirm the optimal effects for your products and processing targets, we conduct preliminary tests. Upon request, we can also provide on-site testing at our lab or rental services for test equipment. Please verify the reliable effects of atmospheric pressure plasma at your location.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Films and thin film materials are prone to adhesion failures and peeling troubles during printing, bonding, and coating due to differences in surface polarity and energy. Our atmospheric pressure plasma equipment is a non-contact, non-chemical surface modification technology that can handle resin-based films such as PP, PE, and PET, as well as metal foils and laminated materials. It significantly improves adhesion through hydrophilization, functional group introduction, and surface cleaning effects. *We are continuously researching special materials such as films and laminated materials. We can also conduct processing evaluations and adhesion tests using our test equipment, so please feel free to consult with us. Let's work together to achieve a more stable surface treatment process with plasma technology.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In next-generation mobility such as EVs and FCVs (fuel cell vehicles), as well as aviation and drones, while lightweighting and the use of composite materials are advancing, challenges have arisen regarding the bonding, adhesion, and durability of dissimilar materials. Our atmospheric pressure plasma equipment is compatible with a variety of materials including carbon, resin, metal, and film, and it achieves improved adhesion and surface activation treatment before adhesion and coating without contact or chemicals. To confirm the optimal effects for your products and processing targets, we conduct preliminary tests. Depending on your needs, we can also offer on-site testing at our lab or rental services for testing equipment. After confirming the changes and effects post-treatment, you can consider implementation with peace of mind. Additionally, we are still in the process of researching special materials and new applications. We aim to deepen and expand our knowledge to utilize plasma technology in more fields. Please feel free to consult with us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"Challenges of Silicone Rubber Adhesion" "Struggling with adhesive costs and environmental impact" to your company **Aqua Corporation's atmospheric pressure plasma device enables "adhesive-free bonding"** to solve these issues. It eliminates the constraints of traditional adhesives (curing time, peeling risk, cost, environmental issues). This next-generation solution directly and strongly bonds silicone rubber to silicone rubber, and glass to silicone rubber, without using chemicals or heat. Additionally, for the challenges of bonding silicone rubber with dissimilar materials, we provide a solution using plasma and adhesive tape! This is not just a change in bonding methods. It is a strategic investment for the future that will dramatically enhance your company's "quality," "cost," "productivity," and "environmental considerations." "Ensuring reliability with overwhelming bonding strength": Plasma activates the surface of silicone rubber at the nano level, achieving direct molecular bonding. It fundamentally eliminates the risk of peeling due to adhesive degradation, significantly improving product lifespan and reliability. "Substantial reduction in costs and processes" maximizes profits: No need for purchasing, applying, drying, or disposing of adhesives. No more compromises in silicone rubber adhesion. This innovative technology creates new value across various fields, including medical, automotive, and electronics.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The performance of corrosion and wear resistance treatments through coatings, painting, and adhesion is determined by the condition of the material's surface. Our atmospheric pressure plasma equipment performs non-contact and non-chemical modification treatment on metal surfaces, achieving surface cleaning, activation, and hydrophilicity. This significantly improves the adhesion of coatings, and enhances durability and corrosion and wear resistance. We can conduct evaluation tests and preliminary verifications with test equipment tailored to your work and objectives. After confirming the changes and effects post-treatment, you can consider implementation with confidence. Additionally, we are still in the process of researching special materials and new applications. We aim to deepen and spread our knowledge so that plasma technology can be utilized in more fields. Please feel free to consult us regarding the feasibility of treatments and collaborative discussions.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our atmospheric pressure plasma device can non-contact treat plastic surfaces such as glass and polypropylene, introducing hydrophilic functional groups to the surface, which is expected to improve cell initial adhesion and uniformity. Since it does not use chemical solutions or vacuum equipment, it is easy to handle and allows for simple, safe, and highly reproducible processing. We can conduct preliminary tests tailored to your products and processing targets. We also offer short-term rentals for internal evaluations upon request. We provide a one-week free rental for first-time users, so please feel free to consult with us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This device uses non-thermal plasma generated under atmospheric pressure to achieve various treatments such as sterilization of pharmaceutical containers and instruments, and surface modification of packaging materials and components, all without the use of chemicals, in a non-contact manner, and in a short time. We can conduct preliminary tests tailored to your products and processing targets. Upon request, we also accommodate on-site testing at our lab and internal evaluations through short-term rentals. We are eager to strongly support pharmaceutical research and development with plasma technology, so please feel free to consult with us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

A "atmospheric pressure plasma device" is a plasma device that can be generated in normal atmospheric conditions without the need for special environments such as vacuum chambers or filling with reaction gases. It is expected to have various effects for applications such as improving hydrophilicity and oleophilicity, coatings, special painting, quality enhancement in adhesion, removal of organic substances that cannot be cleaned, and promoting chemical changes. 【Features】 ■ Usable in normal atmospheric pressure without the need for equipment like vacuum (reduced pressure) chambers ■ Capable of constructing a simple and space-saving system ■ Prototyping and installation for existing devices can be done on a low budget *For more details, please download the catalog or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

A "atmospheric pressure plasma device" refers to a plasma device that can be generated in normal atmospheric pressure without the need for special environments such as vacuum chambers or filling with reaction gases. It is expected to have various effects for applications such as improving hydrophilicity and lipophilicity, coating, special painting, enhancing quality in adhesion, removing organic substances that cannot be cleaned, and promoting chemical changes. 【Features】 ■ Usable in normal atmospheric pressure without the need for equipment like vacuum (reduced pressure) chambers ■ Capable of constructing a simple and space-saving system ■ Prototyping and installation on existing devices can be done on a low budget *For more details, please download the catalog or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

A "atmospheric pressure plasma device" is a plasma device that can be generated in normal atmospheric conditions without the need for special environments such as vacuum chambers or filling with reaction gases. It is expected to be effective for various applications such as improving hydrophilicity and lipophilicity, coatings, special painting, quality enhancement in adhesion, removal of organic substances that cannot be cleaned, and promoting chemical changes. 【Features】 ■ Usable in normal atmospheric pressure without the need for equipment like vacuum (reduced pressure) chambers ■ Capable of building a simple and space-saving system ■ Prototyping and installation on existing devices can be done on a low budget * For more details, please download the catalog or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "atmospheric pressure plasma device" is a plasma device that can be generated in normal atmospheric conditions without the need for special environments such as vacuum containers or filling with reaction gases. Our plasma electrodes utilize the "dielectric barrier discharge" method, which prevents arc discharge by placing a dielectric insulator between metal electrode plates, allowing electrons to be emitted uniformly from the entire electrode. Additionally, by adopting two types of irradiation methods, "direct method" and "jet method," it can accommodate various processes. 【Features】 ■ Can be generated in normal atmospheric pressure ■ Dielectric barrier discharge atmospheric pressure plasma ■ Capable of accommodating various processes through the adoption of two irradiation methods ■ Main Applications - Strength enhancement for adhesion and coating, surface modification, acceleration of chemical changes, development of new methods, experiments, etc. *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "JP-SERIES" is a plasma jet that incorporates a plasma electrode unit within a case and releases activated nitrogen gas from a slit-shaped opening. It has a long irradiation distance and can process uneven non-conductive materials. It is suitable for objects up to 100mm in width and can be expanded and connected with an additional plasma power unit. Please feel free to contact us if you have any requests. ■ Main Applications - Strength enhancement for adhesion and coating, surface modification, promotion of chemical changes, development of new methods, experiments, etc. 【JP-100C Specifications】 ■ Plasma Jet Irradiation Dimensions: 108mm × 0.8mm ■ Required N2 Gas Volume: 70–90L/min ■ Main Unit Dimensions: Width 178 × Height 95mm × Depth 47mm (Including electrode cover, excluding protrusions such as gas fittings and rear grounding terminals) *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "DP-SERIES" is a direct plasma system that generates plasma very close to the surface of the material being processed, resulting in high effectiveness for surface modification, organic matter removal, and other applications, while enabling high-speed processing suitable for production equipment. In atmospheric pressure, the distance of plasma discharge is approximately 1.5mm to 1.7mm, but since it acts directly on the surface of the target material, powerful processing can be achieved in a short time. Additionally, by limiting the power supply to a 100V specification, we have realized low cost and easy operation. ■ Main Applications - Strength enhancement for adhesion and coating, surface modification, promotion of chemical changes, development of new methods, experiments, etc. 【Product Lineup】 ■ DP-2580 ■ DP-2290 *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "SPJ-Series" is a high-power spot-type atmospheric pressure plasma jet that maximizes the efficiency of the plasma electrode, achieving powerful and long-distance irradiation. It can be used for various applications through tube connections. Since it uses N2 (nitrogen) gas, expensive gases are not required. Additionally, it is possible to merge the plasma gases from multiple SPJs. 【Features】 ■ The high-output specification maximizes atmospheric pressure plasma generation, enhancing power (SPJ-02HP). ■ Achieves long-distance irradiation of over 40mm while maintaining a cost-effective configuration with a 100V power supply. ■ Various applications can be realized by connecting tubes or other devices to the plasma irradiation port. ■ Main Applications - Strength enhancement for adhesion and coating, surface modification, promotion of chemical changes, development of new methods, experiments, etc. *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "HPJ-DESKTOP-AT" is an atmospheric pressure plasma jet automatic conveyance tabletop testing machine capable of plasma treatment on uneven materials at an irradiation distance of approximately 10mm. With a plasma irradiation width of 25mm and stable automatic conveyance functionality, it enables uniform surface irradiation with minimal variation. Additionally, it allows for continuous reciprocating motion (1 to 99 cycles), and with the plasma electrode cooling function, it can perform long-duration irradiation. 【Features】 - Conveyance speed (1 to 135mm/sec) and continuous reciprocating motion cycles (1 to 99 cycles) can be set via a touch panel. - Designed with consideration for tabletop work, it is compact and lightweight (required tabletop area during use is approximately 400mm x 400mm). - Capable of testing materials up to 30mm thick as standard. - Built-in digital flow meter for nitrogen gas. ■ Main Applications - Strength enhancement for adhesion and coating, surface modification, promotion of chemical changes, development of new methods, experiments, etc. *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "HPJ-DESKTOP" is a compact and lightweight atmospheric pressure plasma jet handheld testing device designed for desktop work. It features simple operation with just the opening and closing of a nitrogen gas valve and pressing the plasma ON switch. Although all operations are manual, it allows for easy and stable plasma irradiation. Additionally, it can be customized according to usage needs, including sample table size, height adjustment range, protective cover, and air cooling. 【Features】 - Low-temperature plasma jet type that does not select processing materials - Capable of plasma treatment on uneven materials - Allows for uniform surface irradiation - Compact and lightweight, with connection utilities limited to nitrogen gas supply tube and AC100V power supply - Easy to move to different installation locations 【Main Applications】 - Strength enhancement for adhesion and coating, surface modification, promotion of chemical changes, development of new methods, experiments, etc. *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The HPJ-02A is a handheld atmospheric pressure plasma jet testing device that can be used anywhere with just an AC100V power supply and an N2 supply tube connection. It features a plasma jet irradiation width of 25mm, allowing for uniform surface treatment. Additionally, since it uses N2 (nitrogen) gas, there is no need for expensive gases. It is ideal for testing improvements in material development, processing, plating, painting, adhesion, and the development of new methods. 【Features】 - Gun shape that fits comfortably in the hand, making it easy to operate - Simple operation with just a manual valve for N2 supply and a trigger switch at hand - Low-temperature plasma jet type that does not select the target material (irradiation gas temperature below 60°C) - Long irradiation distance, capable of plasma treatment on uneven materials ■ Main Applications - Strength enhancement for adhesion and coating, surface modification, promotion of chemical changes, development of new methods, and experimentation *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The DS-PJ1 is a tabletop atmospheric pressure plasma device that has been miniaturized to the limit while retaining the components of the HPJ-DESKTOP. Despite its small size, it has the same atmospheric pressure plasma processing capability. It emphasizes safety and usability, making it easy and safe for students and those who are not familiar with machinery to use. All operations are manual, but stable plasma irradiation can be achieved. **Features** - The installation area is about half that of the HPJ-DESKTOP. - Place it near inspection equipment to reduce testing time. - Simple operation by just turning the nitrogen gas valve and plasma ON switch. - The plasma ON switch is designed to turn OFF when you release it for safety. **Main Applications** - Strength enhancement for adhesion and coating, surface modification, promotion of chemical changes, development of new methods, experiments, etc. "We want to see the effects with actual materials" or "We want to confirm if it can be used in our internal processes." We conduct preliminary tests to confirm the optimal effects for your products and processing targets. Depending on your needs, we can also provide on-site testing at our lab or rental services for test equipment. Please verify the reliable effects of atmospheric pressure plasma at your location.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The FM-02A is an external, versatile gas flow meter (digital). It is compact and portable, operates with an AC adapter, eliminating the need for electrical work, and allows for easy gas ON-OFF and flow adjustment with a hand valve and adjustment knob. It is ideal not only for professional settings such as adding to existing equipment, prototyping, and development experiments but also for classes and practical training in middle schools, high schools, and universities. You can accurately monitor and adjust gas flow in real-time. 【Sales Background】 While designing and developing atmospheric pressure plasma equipment, we found that commercially available flow meters were not user-friendly, so we developed this product. Initially sold as part of a plasma equipment set, we realized through interactions with customers that many wanted a standalone gas flow meter, leading us to sell it separately. ■ Main Applications - Gas flow adjustment for atmospheric pressure plasma equipment, gas flow adjustment and management for various devices, experimental and development purposes, etc. For more details, please contact Aqua Corporation.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Aqua's plasma electrode adopts a "dielectric barrier discharge" method, which prevents arc discharge by installing dielectric insulation on one or both sides of the metal electrode plate, and utilizes the phenomenon where electrons are widely dispersed across the entire electrode by applying high voltage AC. The applications of atmospheric pressure plasma are still largely unknown, and this device is part of that unexplored field. In addition to this machine, we have a lineup that can accommodate various applications and shapes of target objects. If you have any questions about atmospheric pressure plasma, or if you have inquiries such as "it might be usable" or "I would like to try it," please feel free to contact us. ■ Features - Compact and lightweight for tabletop work - Easy operation allows for uniform surface treatment with minimal variation - Stable testing can be easily and conveniently achieved with adjustable irradiation distance and transport speed ■ Main Applications - Strength enhancement for adhesion and coating, surface modification, promotion of chemical changes, development of new methods, experimentation, etc. *Please contact us if you are interested in our rental service.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Aqua Corporation is divided into four business divisions centered around cleaning equipment, and we are engaged in the manufacturing of custom-made products tailored to our customers' needs, leveraging the high level of technical expertise we have cultivated over many years. We propose high-efficiency, low-cost atmospheric pressure plasma units, as well as various resin processing in our resin processing division, offering processed products that cannot be substituted with off-the-shelf items. You can rely on us for equipment and processed products. 【Business Activities】 ■ Manufacturing of cleaning equipment for LCD production ■ Manufacturing of cleaning equipment for semiconductor production ■ Manufacturing of various small labor-saving devices ■ Sales of food resource recycling equipment ■ Resin processing services *For more details, please refer to our catalog or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration