- Publication year : 2024

1~15 item / All 15 items

Displayed results

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Contact this company

Contact Us Online1~15 item / All 15 items

We would like to introduce an application note on inspection methods for TKY welded joints provided by Eddyfi Technologies (case studies and technical introduction). For example, it addresses the challenges of inspecting fillet welds commonly used in the construction sector. Traditional inspection methods, such as ultrasonic testing (UT), have struggled with detecting flaws in the complex shapes of these welds, resulting in lower probabilities of detection. Eddyfi's solution utilizes advanced portable phased array equipment equipped with software tools that enable effective definition of T and Y joints, achieving improved overall inspection and detection probabilities. For more detailed information, please feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Heat exchangers are used to heat and cool various fluids across a wide range of industrial sectors. This is particularly important for the power generation and petrochemical industries, where equipment reliability is of utmost importance. Standard ECT bobbin probes often struggle to detect circumferential cracks, posing challenges in many cases, but the DefHi probe offered by Eddyfi Technologies can identify various complex shapes inside heat exchanger tubes, allowing for the accurate detection of small circumferential cracks in the tube sheet, sizing, and evaluation of characteristics. Additionally, the inspection speed is eight times faster compared to rotating probes. The DefHi probe is less affected by changes in speed, making it usable regardless of the presence of a mechanical probe feeding device.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

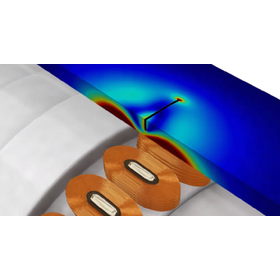

Recent advancements in ultrasonic hardware and software have equipped almost all of our phased array ultrasonic testing devices with real-time full matrix capture and total focusing method. These represent a new generation of inspection technologies already defined in ASME and ISO standards. Austenitic stainless steel materials and dissimilar metal welds possess anisotropic coarse grain structures, resulting in specific behaviors of ultrasonic beams as they propagate through the material. This means high attenuation, high particle noise, beam redirection, and distortion; all of these phenomena ultimately lead to very challenging flaw detection conditions for phased array ultrasonic testing (PAUT). With the next generation of flaw detection equipment and high-performance probes offered by Eddyfi Technologies, we overcome challenges associated with inspecting high-difficulty materials such as dissimilar metal welds, including high ultrasonic attenuation, reduced signal-to-noise ratios, and insufficient coverage.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This case study introduces the economic and environmental benefits of remotely removing marine organisms attached to the hull. Barnacles and other marine organisms that attach to the surfaces of commercial vessels increase drag, reducing the ship's speed and performance, and can increase fuel consumption by up to 40%. To address this issue, Eddyfi proposes a hull cleaning solution using remote robots with robotic crawlers. This technology can reduce the risk of accidents for cleaning personnel, lower costs, and mitigate environmental impacts. For more detailed information, please contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Currently, seamless welded tubes are commonly used in capacitors. These tubes are prone to defects along the weld seam, such as axial cracks, blowholes, poor fusion, and inadequate melting. These defects make it difficult to achieve accurate sizing and classification assessments with standard eddy current bobbin probes. The reason is that the bobbin coil provides an average response over 360°, and the proportion of the weld defects relative to the entire tube wall being inspected by the probe is very small. To address this issue, Eddyfi Technologies has developed the "DefHi Probe," an eddy current array probe that uses multiplexing.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Non-destructive testing of composite materials is an important means of detecting defects and deterioration, and it is crucial to select appropriate inspection methods to ensure the safety and durability of composite materials in the aerospace field. Eddyfi Technologies' inspection solutions address these challenges with a versatile NDT Sweeper and the capability to scan both flat and curved surfaces.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In aging infrastructures such as the petrochemical industry, potential vulnerabilities that plant engineers and maintenance teams should be aware of, particularly high-temperature hydrogen attack (HTHA), are cited as one of the dangerous defects. This defect occurs when hydrogen contained in low-alloy steel changes its atomic form at high temperatures, permeating the steel and forming methane. Once methane is trapped within the metal, tiny bubbles form, ultimately leading to cracking and fissures. Eddyfi proposes advanced, portable ultrasonic inspection tools for the early detection of HTHA, utilizing TOFD, phased array ultrasonic testing (PAUT), and the latest total focusing method (TFM). This technology enables early detection of HTHA, enhancing the safety of critical equipment. For more detailed information, please [contact us].

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Depending on the equipment, high-temperature and high-speed fluids flow towards the 90° bend of carbon steel piping. As a result, it is inevitable that flow-accelerated corrosion (FAC) occurs on the outside of the elbow within the piping. We would like to introduce a technology for detecting CUI/FAC that occurs in the internal carbon steel piping without removing insulation materials or covers during equipment operation. For more detailed information, please contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce the advantages of using ACFM (Alternating Current Field Measurement) technology for inspecting welds on railway tank cars. Compared to conventional inspection methods, ACFM requires less preparation and post-processing, allows for a better understanding of the condition of a wider range of welds, and reduces human and environmental risks. This technology can be applied directly over paint or coatings, improving the reliability of inspections and the probability of detecting defects. Digital records make it easier to manage past inspection data, significantly enhancing asset risk management. Additionally, inspection methods that do not require coating removal provide an environmentally friendly inspection approach and can greatly reduce annual maintenance costs. For more detailed information, please [contact us].

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

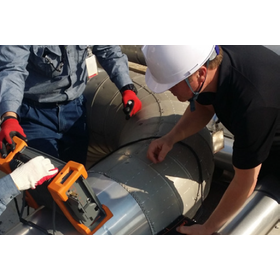

To ensure the smooth operation of transport pipes that transport products to various areas of the production plant, regular evaluation of the piping, including all branch connections, is necessary. Since piping and other plant equipment are subjected to periodic and very high thermal stress from the condensate and steam systems, the risk of fatigue cracking increases. In order to maximize productivity in an economic environment where efficiency is required, a non-destructive testing approach is needed to assess the fitness for service (FFS) of these production facilities.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This application note introduces a case study on the detection of micro-defects using the innovative new product "Sonyks" guided wave testing device, which can operate as a medium-range ultrasonic testing (MRUT) method. It clearly summarizes the features of the new "Magneto Tool," which employs a magnetostrictive method and excels in accurately identifying and locating specific small changes, such as pitting and wall thinning in piping. This technology utilizes high-frequency guided waves that improve resolution of indications, enabling the detection of micro-defects that were difficult to identify with conventional methods. This advancement has the potential to significantly enhance the efficiency and effectiveness of inspections across many different industries. For more detailed information, please contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Aircraft are the foundation of various industries and are subjected to harsh and nearly continuous use, making maintenance extremely important. Eddyfi Technologies has developed an ECA probe capable of inspecting both surface cracks and internal corrosion of multilayer aluminum in the longilon fastener section. For more detailed information, please contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

A pressure vessel is a sealed container designed to hold fluids at a pressure that is significantly different from the surrounding pressure. They are installed throughout refineries. Due to the importance of their function, pressure vessels must undergo rigorous safety inspections regularly. The Shark Probe manufactured by Eddyfi is specially designed to inspect weld line cracks on the surface of such equipment. The probe's spring-loaded fingers are designed to adapt to the shape of the weld reinforcement, allowing it to scan the reinforcement, toe, and heat-affected zone in a single pass. This probe is equipped with a built-in encoder, making it possible to accurately locate defects along the weld. For more detailed information, please contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Friction stir welding is a solid-state joining method widely used in the aerospace industry. In the friction stir welding process, manufacturing parameters such as rotation speed and travel speed can lead to discontinuities at the joint, necessitating the application of non-destructive testing to verify the integrity of the joint. High productivity, work efficiency, and inspection accuracy are central to the quality assurance of newly manufactured aircraft.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Pipelines are essential for the operation of various industries such as water, oil, gas, and power generation, and maintaining pipelines in proper condition is a top priority in these fields. Since they are typically made of iron or steel, corrosion poses a significant threat to safety. Therefore, non-destructive testing for pipeline corrosion is necessary, and ultrasonic testing has been widely accepted as an ideal technology for detecting corrosion in pipelines. Phased array ultrasonic testing allows for accurate wall thickness measurements and can determine the presence of this invisible damage; however, it has been pointed out that there are issues with inspecting pipes along bend sections.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration