1~45 item / All 306 items

Displayed results

Filter by category

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Contact this company

Contact Us Online1~45 item / All 306 items

Filter by category

In the construction industry, accurate information gathering and rapid analysis are essential for progress management. Based on high-resolution image data captured by drones, it is necessary to understand the progress of construction and to detect delay risks early. The PIX4D series operation PCs are designed to address these challenges. 【Usage Scenarios】 - Visualization of overall progress at construction sites - Measurement of earthworks in civil engineering - Understanding site conditions for safety management 【Benefits of Implementation】 - Improved accuracy in progress management - Enhanced work efficiency - Cost reduction

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the automotive industry, collision analysis requires accurate simulation of complex physical phenomena for vehicle safety evaluation. It is particularly important to reproduce elements such as deformation, stress, and energy absorption during a collision with high precision. The accuracy of the simulation is directly linked to design optimization and safety improvement, making a high-performance PC essential. Our COMSOL operational PCs address these challenges and enable more efficient analysis. 【Usage Scenarios】 - Evaluation of automotive collision safety - Optimization of vehicle body structure - Analysis of energy absorption performance during collisions 【Benefits of Implementation】 - Reduction in analysis time - Shortening of design cycles - Improvement in product safety

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Ansys Digital Twin is a technology and solution that combines Ansys's long-standing physical simulation technology (multiphysics) with AI/machine learning to accurately replicate and synchronize real-world products and processes in a virtual space. It is offered through a range of products such as Ansys Twin Builder and Ansys TwinAI, enabling predictive maintenance, performance optimization, and the creation of new services from product design and development to operation and maintenance. It features a "hybrid digital twin" that merges physical models with data models (AI/ML), providing high-precision predictions and real-time insights. Therefore, the performance of CPU, memory, and GPU becomes crucial.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The completely open-source protein structure prediction software "openfold3" is a fully open-source biomolecular complex structure prediction model developed with the aim of reproducing the functionalities of Google DeepMind's AlphaFold3. It has become a software of great interest as it allows for free use, retraining, and application development by research institutions and companies alike. We are selecting the most suitable models for such software.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The next-generation sequencing analysis software "CLC Genomics Workbench" is a software that allows for integrated analysis with an intuitive GUI operation. It features advanced functions such as assembly, mapping, and variant calling (mutation detection), supports a wide range of fields including RNA-seq and metagenomics, offers flexibility through rich workflows and plugins, is compatible with Windows/Mac/Linux, and includes visualization capabilities. It is used by both experts and beginners, supporting research efficiency and collaboration. This is a recommended PC for those looking for the ideal setup for such software!

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the automotive industry, electromagnetic compatibility (EMC) measures are essential for ensuring product safety and reliability. Particularly with the increase in onboard electronic devices, EMC issues have become more complex, necessitating efficient countermeasures. The recommended PC for EMCoS Studio is designed to fully leverage the advanced simulation capabilities of EMC Studio, contributing to solving challenges in EMC design for automotive manufacturers. 【Usage Scenarios】 - EMC design in automotive manufacturing - EMC analysis of wire harnesses - EMC evaluation of onboard electronic devices 【Benefits of Implementation】 - Increased efficiency in EMC design - Reduced product development time - Lower costs for EMC testing

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the automotive industry's collision safety evaluation, accurate analysis of composite materials is essential. To achieve a balance between vehicle lightweighting and safety, it is necessary to predict the behavior of composite materials in detail and conduct optimal design. J-Composites Dynamic PC provides high computational power and stability to address this challenge. By using J-Composites/Form Modeler, it is possible to easily set up complex composite laminate models and export them as input files for LS-DYNA. This allows for more accurate prediction and evaluation of defects such as wrinkles during collisions, contributing to the design of safer vehicles. 【Application Scenarios】 - Automotive collision safety simulations - Component design using composite materials - Vehicle development that balances lightweighting and safety 【Benefits of Implementation】 - Improved collision safety - Streamlined design processes - Reduced product development time

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the automotive industry, weight reduction is essential for improving fuel efficiency and performance. The use of composite materials is an effective means of achieving weight reduction, but predicting material properties poses a challenge. Digimat's operation PC performs material property predictions considering the microstructure of composite materials, supporting product design. 【Application Scenarios】 * Development of automotive parts using composite materials * Optimal design based on material properties * Balancing weight reduction and performance 【Effects of Implementation】 * Optimization of material selection * Streamlining of the design process * Reduction of product development time

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the automotive industry, reducing vehicle weight is a crucial challenge for improving fuel efficiency and minimizing environmental impact. To achieve weight reduction, it is essential to adopt lighter materials while maintaining strength. J-OCTA simulates the properties of polymer materials such as resins and rubbers to support optimal material selection. This helps reduce the number of experiments and contributes to shortening the development period. 【Application Scenarios】 - Design of components using polymer materials - Prediction and optimization of material properties - Development of lightweight materials 【Benefits of Implementation】 - Increased efficiency in material development - Reduction in development costs - Improvement in product performance

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the drug discovery industry, accurately predicting the structure and interactions of molecules that could become drug candidates is a crucial factor that influences the success of new drug development. AI models like AlphaFold3 innovate this process by predicting the structures and interactions of complex molecules such as proteins, DNA, RNA, and ligands with high precision. However, these models require high-performance GPUs, and computational capacity can become a bottleneck. Our HPC is equipped with the recommended NVIDIA H200 GPU for running AlphaFold3, accelerating target exploration in drug discovery research. 【Use Cases】 - Identification of drug discovery targets - Molecular docking simulations - Screening of drug candidate compounds 【Benefits of Implementation】 - Increased efficiency in drug discovery research - Reduced new drug development timelines - Lower research costs

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the printing industry, detecting misalignment in printed materials is crucial for consistently supplying high-quality prints. Particularly in high-volume printing or high-speed printing, even slight misalignments can lead to a decline in quality or customer complaints. The AI appearance inspection system starter set contributes to the efficiency of quality management by quickly and accurately detecting misalignment in printed materials. 【Usage Scenarios】 - Inspection of misalignment in printed materials - Inspection for ink bleeding and fading - Inspection for foreign object contamination 【Benefits of Implementation】 - Reduction of defective products - Improvement in quality - Cost reduction

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the metal industry, it is essential to accurately detect the presence or absence of distortion to ensure product quality. Particularly in metal products that have undergone processes such as pressing and welding, even slight distortions can affect the strength and functionality of the product. An AI visual inspection system can quickly and accurately detect fine distortions that may be overlooked in visual inspections. Our AI visual inspection system starter set is easy to implement, allowing you to begin distortion inspections immediately after purchase. 【Usage Scenarios】 - Distortion inspection after the pressing of metal parts - Distortion inspection after welding - Distortion inspection during the assembly process of metal products 【Benefits of Implementation】 - Cost reduction through early detection of defective products - Quality improvement through enhanced inspection accuracy - Increased productivity through reduced inspection time

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the food industry, product shortages are directly linked to opportunity loss and are a major factor in decreasing customer satisfaction. In particular, shortages caused by foreign object contamination or packaging defects can undermine a company's trust. The AI visual inspection system addresses these challenges by enabling rapid and accurate inspections, thereby reducing the risk of shortages. Our AI visual inspection system starter set balances food quality management and efficiency, contributing to the strengthening of a company's competitiveness. 【Use Cases】 - Inspection for foreign object contamination in food - Inspection for packaging damage or printing errors - Detection of expired products 【Benefits of Implementation】 - Reduction in shortage rates - Improvement in customer satisfaction - Reduction of food waste - Increased efficiency in quality management

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the automotive industry, improving collision safety is one of the most important challenges. Vehicle collision simulations are essential for evaluating occupant protection performance and meeting safety standards. The introduction of the preprocessor PRIMER, which can efficiently construct large-scale and complex analysis models, is required. PRIMER is almost 100% compatible with Ansys LS-DYNA, ensuring data reliability. ARUP software significantly reduces the man-hours required for model creation, providing a modeling environment that balances efficiency and reliability. 【Usage Scenarios】 - Design departments of automobile manufacturers - Collision safety performance evaluation organizations - Research and development institutions 【Effects of Implementation】 - Reduction in analysis model creation time - Improvement in analysis accuracy - Streamlining of safety performance evaluation

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the automotive industry, ensuring collision safety is the top priority. Since vehicle design changes occur frequently, a rapid response is required. To enhance the accuracy of collision analysis, it is essential to consider the initial conditions of press-formed materials, such as sheet thickness and plastic strain. However, traditional analysis methods necessitate changes to the analysis model and re-simulation with each design change, hindering quick responses. HYCRASH addresses this issue by automatically generating initial conditions for Ansys LS-DYNA. 【Usage Scenarios】 - Collision analysis in automotive manufacturers - Rapid analysis response during design changes - Utilization of press forming simulation results 【Benefits of Implementation】 - Improved analysis accuracy - Reduced design period - Efficient response to design changes

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the aerospace industry, reducing the weight of aircraft structures is essential to achieve both safety and fuel efficiency. In particular, evaluating the strength of structures against collisions and impacts is a critical issue during the design phase. Altair Radioss accurately simulates high-speed and large deformation phenomena such as collisions, drops, and failures, enabling safety and reliability assessments without relying on prototypes or physical tests. 【Application Scenarios】 - Collision safety design of aircraft components - Impact resistance evaluation of composite materials - Structural analysis in lightweight design 【Benefits of Implementation】 - Shortened development time - Improved design quality - Cost reduction

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the semiconductor industry, detecting minute pattern anomalies is essential to ensure product quality. Even slight abnormalities in the manufacturing process can significantly impact product performance. The AI visual inspection system starter kit can be used immediately after purchase, streamlining the detection of pattern anomalies. 【Usage Scenarios】 - Pattern inspection of semiconductor wafers - Pattern inspection of electronic components - Pattern inspection of substrates 【Benefits of Implementation】 - Improved yield through early detection of defects - Enhanced inspection accuracy - Reduced inspection time

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the plastic industry, detecting burrs that affect product quality is crucial. The occurrence of burrs not only compromises the functionality and appearance of products but also leads to the production of defective items in the manufacturing process. The AI visual inspection system starter set efficiently detects burrs in plastic products and enhances quality control. 【Application Scenarios】 - Burr inspection of plastic molded products - Burr inspection of injection-molded products - Burr inspection after machining 【Benefits of Implementation】 - Reduction of defective products - Shortening of inspection time - Stabilization of quality

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the electronic components industry, thorough elimination of foreign matter is required to ensure product quality. Contamination during the manufacturing process can lead to product defects and performance degradation, potentially undermining customer trust. AI visual inspection systems enhance quality control by accurately detecting fine foreign objects that may be overlooked during manual inspections. 【Usage Scenarios】 - Foreign matter inspection on electronic component manufacturing lines - Detection of scratches, chips, and dirt on product surfaces - Streamlining quality control in the manufacturing process 【Benefits of Implementation】 - Reduction in the occurrence of defective products due to foreign matter contamination - Strengthening of quality control through improved inspection accuracy - Reduction in time and costs associated with manual inspections

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the automotive industry, safety is one of the most important issues. To enhance occupant protection performance during collisions, it is necessary to accurately understand the vehicle's collision and destruction behavior and reflect this in the design. There is a demand to visualize behaviors under extreme conditions, which are difficult to reproduce through experiments alone, digitally, enabling safety and reliability evaluations without relying on prototypes or actual tests. Altair Radioss is software that accurately reproduces high-speed and large deformation phenomena such as collisions, drops, and destruction, contributing to reduced development costs and improved product quality. 【Application Scenarios】 - Automotive collision safety design - Evaluation of occupant protection performance during collisions - Evaluation of parts' impact resistance - Strength evaluation of vehicle body structures 【Effects of Implementation】 - Reduction of collision analysis time - Shortening of design cycles - Improvement of product safety - Reduction of development costs

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the automotive industry, detecting paint and component scratches is crucial for maintaining product quality. Particularly in cars, where appearance is emphasized, even minor scratches can become a significant issue. Manual inspections are time-consuming and costly, and they carry the risk of oversight. The AI visual inspection system starter kit streamlines scratch detection and contributes to improved quality control accuracy. 【Use Cases】 - Scratch inspection on painted surfaces - Scratch inspection on components - Quality control on the manufacturing line 【Benefits of Implementation】 - Cost reduction through automation of inspections - Improved inspection accuracy - Mitigation of losses through early detection of defective products

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

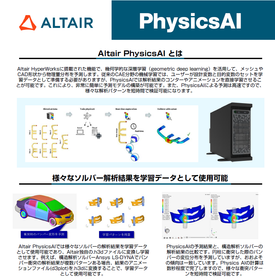

In the automotive industry, collision analysis requires repeated complex simulations for safety evaluation. Long analysis times become a challenge with each design change, often leading to delays in the development cycle and increased costs. The PhysicsAI operating PC learns from past CAE analysis data and streamlines the consideration of designs in the early stages, achieving improved development speed. 【Use Cases】 - Evaluation of collision safety - Optimization of body structure - Efficiency in parts design 【Benefits of Implementation】 - Reduction in design consideration time - Decrease in the number of prototypes and analyses - Shortening of the development period

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Altair Radioss is an impact analysis software that uses an explicit time integration method to accurately reproduce high-speed and large deformation phenomena such as collisions, drops, and destruction. By visualizing behaviors under extreme conditions that are difficult to replicate in experiments, it enables safety and reliability evaluations without relying on prototypes or actual tests, achieving reductions in development costs and improvements in product quality. ■ Main Features and Characteristics - Supports dynamic phenomenon analysis such as collisions, drops, destruction, and explosions using explicit methods - High-precision simulations considering structural deformation, contact, fracture, and material nonlinearity - Equipped with a wide range of material models including metals, plastics, and composites - Capable of analyzing complex physical phenomena including fluid-structure interaction (FSI) - Supports parallel computing with MPI/OpenMP for fast processing of large-scale models - Extensive implementation track record in automotive, aerospace, defense, electronics, and industrial machinery - Integrated with the HyperWorks platform for seamless collaboration in pre-processing and visualization - Applicable to a wide range of engineering uses including research and development, collision safety design, and impact resistance evaluation

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

PhysicsAI is an AI-based software for accelerating physical simulations that learns from past simulation data to quickly predict physical behavior for design shapes. Rather than replacing traditional CAE analysis, it utilizes accumulated analysis assets to streamline considerations in the early stages of design, achieving improved development speed while reducing the number of prototypes and analyses. ■ Main Features and Characteristics - AI learns from past CAE analysis results (structural, fluid, thermal, etc.) to quickly predict physical behavior. - By simply inputting a CAD model, results such as deformation, stress, and temperature are visualized instantly. - Design consideration speed is improved by tens to up to 1,000 times compared to conventional analysis. - Supports a wide range of CAE areas, including structural analysis, fluid analysis, and manufacturing process analysis. - Optimally suited for screening purposes in the early stages of design, accelerating optimization and design exploration. - Enhances quality and reproducibility through data-driven design utilizing CAE results. - Integrated with the HyperWorks platform, seamlessly linking with existing analysis workflows. - Applicable to a wide range of engineering uses, including research and development, manufacturing technology, and design departments.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Next-generation sequencing (NGS) is a technology that can decode the base sequences of DNA and RNA much faster and in larger quantities than traditional methods. It enables the simultaneous parallel analysis of DNA fragments, significantly expanding the scale of genomic research. For processing NGS, it is beneficial to have a higher number of CPU cores. Additionally, having more than 256GB of memory and a graphics card is also recommended, making this model a recommended configuration.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The AI model "AlphaFold3," which predicts the structures and interactions of complex molecules with high precision, is capable of accurately predicting not only protein structures but also those of complex molecules such as DNA, RNA, and ligands. It aims to significantly advance traditional protein structure prediction and accelerate research across the life sciences, including drug development and genomic studies. As a result, high-performance GPUs are essential, and this model is equipped with the H200.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

◆Automatic Generation of Initial Conditions for Ansys LS-DYNA: Rapid Response to Vehicle Design Changes In collision analysis, we aim for further accuracy improvements by considering the initial conditions of press-formed materials, such as sheet thickness and plastic strain. Since FEM meshes are created according to the respective purposes for press forming analysis and collision analysis, it is common to map the results of press forming simulations to the collision model due to differences in modeling of the R parts and mesh sizes. However, this method requires time for changing the analysis model or re-simulating when design changes occur, making rapid response difficult. HYCRASH solves this issue by automatically generating initial conditions for Ansys LS-DYNA using the collision model itself! ◆Automatic Generation of Collision Model Data: Improving Analysis Accuracy and Efficiency The only required input data is the collision analysis model. By simply specifying the part number of the press-formed material, HYCRASH conducts forming analysis for all those parts and fully automatically generates new collision model data. Since the collision model data includes initial conditions such as sheet thickness and plastic strain from the forming analysis results, it enables highly accurate collision analysis.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

◆Efficient and Reliable Model Creation ARUP software provides a dedicated preprocessor, PRIMER, designed to efficiently construct large and complex analysis models for automotive collision and occupant safety analysis. PRIMER is nearly 100% compatible with Ansys LS-DYNA and is equipped with extensive checking functions to ensure data reliability. By accurately understanding complex reference relationships, it prevents data loss and the destruction of reference relationships, supporting the stability of the analysis. Additionally, as a feature specialized for automotive safety analysis, it includes a dedicated set of tools that efficiently handle tasks such as positioning occupant dummy models, fitting seat belts, and folding airbags, significantly reducing the man-hours required for model creation. It can also flexibly accommodate user-specific procedures and internal standards, achieving a modeling environment that balances efficiency and reliability. ◆Rapid Result Evaluation and Automated Report Generation With REPORTER, result processing and report creation are automated, allowing for efficient handling of multiple specifications and numerous analysis cases. Reports can be output in HTML or PDF format, making it a significant advantage for quickly and consistently sharing and reporting results.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

High-end GPUs consume a lot of power, and in a typical 100V 1500W environment, it is often only possible to install one unit. This model can accommodate 2 to 4 high-end GPUs in a 100V environment by equipping it with two large-capacity power supplies. There is no need to prepare a dedicated server room or carry out 200V electrical work, making it possible to introduce a machine that is optimal for AI development. ■Main Features and Characteristics - Supports a theoretical maximum power consumption of 3000W - Can be configured with up to 4 high-end GPUs - Rack-mounted models are also available (6U size) - CPU, memory, and storage can be customized according to your needs and budget

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This model features two physical storage units, each with Windows and Ubuntu installed, making it a dual OS setup. By sharing the hardware resources of a single PC, significant cost savings can be achieved, allowing for full utilization of the PC's specifications compared to using Ubuntu with WSL2. ■ Main Features and Characteristics - It is possible to switch between operating systems on a single PC even if the supported OS differs by software. - AI development and general-purpose applications can be consolidated into one PC. - There are no limitations on hardware resources due to virtualization, allowing for full specifications to be utilized. - Customization is possible according to your needs.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The resin injection molding simulation software ASU/MOLD visualizes processes such as filling, warpage and shrinkage analysis, and mold cooling using a three-dimensional solid mesh, providing high-precision results in a short time. It is utilized in various stages from product design to mold creation and molding sites. There are no limitations on the number of CPU cores for calculations on a single PC. It is possible to execute multiple calculation jobs simultaneously, allowing for quick feedback cycles through the comparison of results based on mold shapes and molding conditions. We are configuring the optimal PC for that software.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

<Research content using quantum chemistry calculations> - Prediction and analysis of material properties (prediction of stable structures, analysis of electronic states) - Analysis of chemical reactions (transition of energy, calculation of energy amounts) - Development of new materials and substances (design of functional materials, pharmaceutical development, development of new nanomaterials) To those in research and development departments as mentioned above, we introduce HPC for the quantum chemistry calculation software 'BIOVIA TURBOMOLE'.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

DEFORM is simulation software designed for high-precision analysis of deformation, stress, and temperature distribution in metal plastic processing. It supports a wide range of plastic processing processes such as forging, rolling, cutting, sintering, and joining, and achieves prototype reduction, process optimization, and quality improvement by numerically reproducing actual processing phenomena. ■ Main Features and Characteristics - High-precision process simulation for analyzing deformation, stress, and temperature distribution in metal plastic processing - Support for various plastic processing methods including forging, rolling, cutting, and extrusion - Visualization of load, friction, and stress concentration on molds to assist in extending mold life - Stabilization of quality through optimization of processing conditions, lubrication states, and temperature parameters - High-precision mesh generation and remeshing capabilities that accommodate complex shapes and multi-stage processes - Realistic deformation behavior reproduction through material models that consider temperature dependence - Equipped with a verified database that can be linked with experimental and manufacturing data - An analytical environment that supports a wide range of process design and optimization from research and development to production technology.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

JSCAST is a simulation software specifically designed for casting that accurately reproduces the flow, solidification, and defects of the casting process. It enables the optimization of materials, molds, and cooling conditions digitally, without relying on skilled craftsmanship or physical prototypes. ■ Main Features and Characteristics - High-precision casting process simulation integrating thermal fluid analysis and solidification analysis - Prediction and visualization of defects such as flow issues, gas entrapment, and shrinkage cavities - Improvement of yield through optimization of molds, cooling pipes, and pouring conditions - Flexible mesh generation that accommodates complex shapes and multi-material casting - Verified physical property database with high consistency with experimental data - Analytical environment operable in both cloud and on-premises settings - Modular structure supporting a wide range of applications including education, research, and production technology

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

J-OCTA is a multi-scale simulation software that predicts the properties of high-performance materials, such as resins, rubber, nanocomposites, thin films, inks, and batteries, as well as research and development in the life sciences field, including drug discovery and formulation, from atomic scale to micrometer scale on a computer. It can be used as a knowledge discovery tool to understand the mechanisms of complex phenomena that cannot be fully grasped through experiments alone, as well as a data creation tool for informatics.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Digimat is software specialized in composite material simulation. To apply composites in products, predicting the unique physical properties of composites is key. Digimat predicts the material properties of composites from the material properties and microstructural information of the matrix and inclusions. Furthermore, we provide an interface for structural analysis that takes into account the distribution of material properties resulting from the molding process using the predicted material properties. Digimat supports the research and development of new materials and product design using composite materials.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Industry-standard software that analyzes 3D measurement data and guarantees adherence to design specifications. PolyWorks | Inspector is a three-dimensional inspection and quality control software that can accurately analyze vast amounts of point cloud data obtained from CMMs (Coordinate Measuring Machines), laser scanners, optical scanners, and more, by matching it with CAD models. It is adopted across a wide range of manufacturing sectors, including automotive, aerospace, and precision machinery, contributing to quality assurance and improved production efficiency. ■ Key Features - Point cloud processing capabilities: noise removal, mesh generation, surface reconstruction - CAD matching/verification: error color map display, GD&T (Geometric Dimensioning and Tolerancing) analysis - Automation support: automation of inspection sequences, automatic report generation - Data integration: compatible with SPC (Statistical Process Control) and PLM systems ■ Benefits of Implementation - Quantifies the differences between design and actual products, ensuring product quality - Streamlines inspection processes and eliminates reliance on individual expertise - Builds a digital quality foundation compatible with smart factories To comfortably process vast point clouds and CAD models, a combination with a high-end workstation equipped with a high-performance CPU, professional GPU, and large-capacity memory is optimal.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The high-precision automatic colony counters Scan3000AI and Scan5000AI, equipped with AI, perform detection and counting using AI trained on over one million images. They achieve a 25% increase in accuracy compared to traditional colony counters and can now identify bubbles and markings that were previously difficult to distinguish. We have selected HPCs that we recommend for your use.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Imaris is software for visualizing and analyzing 3D and 4D image data from microscope images. Due to the nature of image processing, a GPU is essential for this task. If the GPU itself heats up, the analysis speed will decrease, so this model equipped with a dedicated GPU fan is recommended.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Cryo-Electron Microscope Analysis HPC Workstation Accelerate single-particle analysis from large-scale image data consisting of thousands to tens of thousands of images!! We propose a high-performance computing system for advanced analysis that supports the three-dimensional structural analysis of biomolecules. We support the acceleration and time-saving of research and development with a cryo-electron microscope and image detector that can efficiently collect high-quality electron microscope images, along with a computer capable of processing high-precision image analysis programs at high speed. *Recommended for users of single-particle analysis software such as RELION and CryoSPARC.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Set model of a 2U head server and a large-capacity JBOD storage unit exceeding 1PB! Equipped with 60 high-durability SAS 18TB HDDs (1080TB), this model balances large capacity and reliability. It can be widely used from large-scale cloud storage infrastructure to laboratory file servers. The RAID controller provided as a set adopts the industry-standard MegaRAID SAS3916, ensuring stable operation in conjunction with the storage unit. Set model of a 4U AI server and a large-capacity JBOD storage unit exceeding 1.5PB! Equipped with 60 high-durability SATA 26TB HDDs (1560TB), this model balances large capacity and reliability. It can be widely used from large-scale cloud storage infrastructure to laboratory file servers. The RAID controller provided as a set adopts the industry-standard MegaRAID 9560-16i, ensuring stable operation in conjunction with the storage unit.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

J-Composites/Form Modeler is a model creation tool for resin composite press molding analysis. It automatically constructs material models for press molding from various test results, allowing for easy setup of complex composite stacking models through a dedicated user interface, and can export them as input files for LS-DYNA. Additionally, by considering both in-plane and out-of-plane material properties, it more accurately predicts and evaluates defects such as wrinkles that occur during the molding of dry fiber substrates and thermoplastic/thermosetting prepregs.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

EMCoS Studio enables the simulation of various EMC phenomena, from emissions and immunity to crosstalk, and it has particularly strong analytical capabilities regarding wire harnesses. Its excellent operability and analytical performance have been well received by many automotive and electronics manufacturers in Europe and Japan. Please make use of EMCoS Studio for efficient EMC design.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The Aurora Imaging Library is an "industrial image processing library with excellent embedded capabilities and stability," characterized by its suitability for system development focused on device integration and control. - Developer: Matrox Imaging, Canada - Overview: A comprehensive software library developed for industrial image processing and machine vision - Availability: Usable through APIs such as C/C++, C#, .NET. GUI-based development is also possible in conjunction with Aurora Design Assistant - Main Features: - Image acquisition and preprocessing (filtering, geometric transformations, etc.) - Pattern matching, dimension measurement, character recognition (OCR) - Color-based inspection, appearance inspection - 3D image processing (stereo, laser, point cloud analysis) - Classification and detection using deep learning (supports NVIDIA GPU) - Characteristics: - Modular, allowing only the necessary functions to be integrated - In SDK format, enabling flexible integration into embedded devices and dedicated equipment - Widely used by inspection equipment manufacturers and for research purposes, with strengths in real-time performance and stability.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Equipped with NVIDIA H200 Tensor Core GPUs, it enables smooth processing! A super high-performance model boasting an astonishing 141GB of GPU memory per unit!

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration