1~45 item / All 58 items

Displayed results

Filter by category

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Contact this company

Contact Us Online1~45 item / All 58 items

Filter by category

Reducing "excess inventory," which puts pressure on corporate profits, is an important issue for many businesses. The causes of excess inventory include low accuracy in demand forecasting and the personalization of sales and ordering plans. This article thoroughly explains the causes of excess inventory, the associated risks, and specific solutions. If excess inventory is left unaddressed, it can lead to increased storage costs and worsened cash flow; however, by implementing appropriate measures, it is possible to avoid these risks and efficiently reduce inventory. Various approaches will be introduced, from utilizing short-term discount sales to reviewing inventory management processes in the medium to long term, providing concrete strategies to fundamentally reduce excess inventory. *For more details, you can view the related links. For more information, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Understanding the difference between "excess inventory" and "overstock" in inventory management is key to cost reduction and operational efficiency. However, few people may know exactly what these terms mean and how to address them. This article will clearly explain the differences between excess inventory and overstock, revealing the causes and risks associated with each. Additionally, it will detail specific methods to reduce these inventories and fundamental measures to prevent their occurrence. In particular, we will explore how to leverage demand forecasting techniques to proactively prevent the emergence of excess inventory. By gaining this information, you can take a step towards solving inventory management issues and achieving business efficiency. *For more details, you can view the related links. For further information, please download the PDF or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In inventory management, excess inventory puts pressure on costs, while stockouts lead to lost opportunities, making balanced inventory reduction an important challenge for companies. However, to promote inventory reduction, it is necessary to understand specific methods and how to utilize AI, and to execute them efficiently. This article thoroughly explains the objectives and benefits of inventory reduction, how to proceed, and the use of AI, providing information that helps optimize inventory management. Let's learn how to reduce storage costs and improve cash flow through inventory reduction. *For detailed content of the blog, you can view it through the related links. For more information, please download the PDF or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

For companies aiming to streamline inventory management, what approaches to inventory management are most optimal for efficiency? This article will provide a detailed explanation of the fundamental concepts of inventory management, as well as specific methods to enhance its efficiency. It offers tips to solve the challenges faced by many companies struggling with inventory management issues and significantly improve operational efficiency. We will introduce the latest inventory management techniques utilizing AI and systems to overcome challenges such as reliance on specific individuals and inability to respond to demand fluctuations. By reading this, you will gain insights into the benefits of streamlining inventory management and practical solutions for effective inventory management. *For more details, you can view the related links. For further information, please download the PDF or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

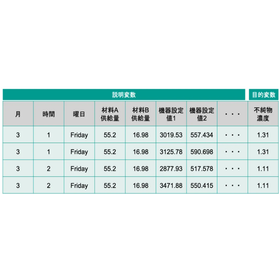

The PSI management table is an essential tool for efficiently managing a company's production, sales, and inventory, allowing for centralized management of production (Production), sales (Sales), and inventory (Inventory) through the PSI management table. By utilizing the PSI management table, challenges such as excess inventory and stockouts can be addressed, promoting operational efficiency. In particular, as supply chains become more complex, the importance of the PSI management table is increasing. This article provides a detailed explanation of the basic structure and utilization methods of the PSI management table, as well as practical operational points for its implementation. It also touches on specific steps for creating a PSI management table using Excel and how AI can be utilized for demand forecasting in PSI management. Please read to the end. *For more detailed information, you can view it through the related links. For more details, please download the PDF or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The PSI (Production, Sales, Inventory) management system is an essential system for integratively managing sales, production, and inventory in an increasingly complex supply chain. In today's world, where demand fluctuations are intense, an appropriate PSI management system is indispensable. This article will provide a detailed explanation of the basic mechanisms and benefits of PSI management, as well as the management systems that should be implemented. Without the introduction of an appropriate PSI management system, issues such as excess inventory and stockouts can arise, leading to a reliance on specific individuals and a decrease in planning accuracy. By implementing a PSI management system, we can prevent surplus inventory and aim for cost reduction and maximization of sales opportunities. *For more detailed information, please refer to the related links. For further details, you can download the PDF or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In modern corporate activities, AI forecasting is gaining attention as a means to maximize sales. The challenge many companies face is how to effectively utilize AI forecasting to improve sales. This article will help you find the best approach to AI forecasting for your business operations by explaining the mechanisms of AI forecasting, providing specific case studies, and comparing AI tools. By leveraging AI forecasting, it becomes possible to improve prediction accuracy, reduce labor hours, and optimize inventory and personnel, ultimately leading to an expected increase in sales. In particular, we introduce specific applications of AI forecasting across various industries, including retail, food service, manufacturing, and services. *For more detailed content of the blog, you can view it through the related links. For more information, please download the PDF or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In business activities, accurately predicting future sales is the key to success. However, many people may struggle with how to calculate sales forecasts and how to utilize Excel effectively. By leveraging Excel, it is possible to quickly create sales forecasts while keeping costs down. However, analyzing external factors that cannot be captured by Excel alone is also an important challenge. This article thoroughly explains the basics of sales forecasting, from fundamental concepts to calculation methods using Excel, and introduces practical points to enhance the accuracy of sales forecasts. *For detailed content of the blog, you can view it through the related links. For more information, please download the PDF or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In PSI management, it is important to effectively connect production, sales, and inventory. However, there are many constraints when managing PSI with Excel. PSI management using Excel faces issues such as the burden of data updates, the risk of human error, and a lack of flexibility. Therefore, to streamline PSI management, it is necessary to implement a system for centralized management and real-time data visualization. This article will provide a detailed explanation of the basics of PSI management, the limitations of Excel, and the implementation of systems for efficient PSI management. *For more details, you can view the blog through the related links. For further information, please download the PDF or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

AI-driven demand forecasting is a noteworthy system that realizes the efficiency of various operations such as sales, inventory, production, and procurement. In recent years, we have entered an era where future demand can be predicted with high accuracy using data and AI, without relying on experience or intuition. This article will clearly explain the mechanisms, methods, benefits, implementation steps, and case studies of "demand forecasting AI." *For more detailed information, you can view it through the related links. For further details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Excess inventory refers to a situation where stock levels exceed sales plans, posing a significant management risk for companies. When excess inventory occurs, various disadvantages arise, such as increased storage costs, worsened cash flow, and decreased product value. Furthermore, if inventory remains in the warehouse for an extended period, it can lead to reduced operational efficiency and waste losses, ultimately putting pressure on profit margins. To prevent these disadvantages of excess inventory, it is crucial to correctly understand the causes and take early measures. This article will clearly explain the main causes of excess inventory and the differences between stagnant inventory and surplus inventory, as well as introduce specific strategies to minimize risks. *For more detailed content of the blog, please refer to the related links. For more information, you can download the PDF or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

For food manufacturers, the accuracy of demand forecasting is a crucial factor that influences management. If forecasts are incorrect, it can lead to food waste due to excess inventory or lost sales opportunities due to stockouts, which can pressure profits. In recent years, the response to the SDGs and intensified market competition have revealed the limitations of traditional forecasting methods that rely on intuition and experience. This is where AI-driven demand forecasting comes into focus. High-precision forecasts based on vast amounts of data can reduce food waste and maximize profits, leading to sustainable management. Particularly for food manufacturers, utilizing AI has become urgent to capture the highly variable demand. This article will explain the environment surrounding food manufacturers, the challenges of demand forecasting, the benefits of AI demand forecasting, and AI demand forecasting services that can be utilized with no-code solutions. *For more detailed information, please refer to the related links. For further details, you can download the PDF or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Demand forecasting in inventory management is a crucial initiative that significantly affects a company's profitability and customer satisfaction. If demand cannot be accurately assessed, risks such as increased costs due to excess inventory and lost sales opportunities due to stockouts can arise. Conversely, effective demand forecasting can lead to inventory optimization, improved operational efficiency, and even increased sales. This article will clearly explain the basics of demand forecasting in inventory management, representative formulas and methods, as well as the latest initiatives utilizing AI. *For more detailed information, you can view the related links. For further details, please download the PDF or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the manufacturing industry, demand planning is essential for achieving stable supply and efficient production. Proper demand planning can prevent excess inventory and stockouts, optimizing production efficiency in factories and the entire supply chain. However, in recent years, it has become increasingly difficult to ensure sufficient accuracy with traditional methods due to intensified demand fluctuations and the complexity of supply chains. This is where AI-driven demand forecasting has gained attention. By implementing AI, manufacturing sites can conduct their own forecasts, supporting quick and flexible decision-making. This article will clearly explain the basics of demand planning in manufacturing, how to create it, challenges and solutions, as well as the latest trends and the use of AI tools. *For more detailed information, please refer to the related links. For further details, feel free to download the PDF or contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In inventory management and ordering operations, it is important to prevent stockouts while keeping inventory costs low. The key to this is inventory optimization that combines lead time and demand forecasting. Lead time is the period from order placement to delivery, while demand forecasting is a method for estimating future sales volumes. If either is inaccurate, the risk of overstocking or stockouts increases. In today's rapidly changing market, the importance of optimizing both simultaneously has never been greater. This article will clearly explain the basics of lead time and demand forecasting, how to set safety stock, optimize ordering methods, and examples of utilizing AI tools. *For more detailed content of the blog, you can view it through the related links. For more information, please download the PDF or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Are you struggling with losses or stockouts due to inventory imbalances? Many of the causes stem from conducting ordering operations with low accuracy in demand forecasting. In recent years, an increasing number of companies have dramatically improved their ordering accuracy through demand forecasting utilizing AI and data analysis. In this article, we will comprehensively explain practical information covering the relationship between demand forecasting and ordering, specific forecasting models, utilization methods by ordering type, and the benefits of automation using AI tools. *You can view the detailed content of the blog through the related links. For more information, please download the PDF or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In today's market environment, the accuracy of demand forecasting significantly influences a company's performance. However, accurately capturing complex consumer trends and external factors is not easy. This is where AI-driven demand forecasting comes into focus. This article clarifies the mechanisms and advantages of AI-driven demand forecasting, as well as the algorithms used, and explains its effectiveness through actual implementation examples. *For more detailed information, please refer to the related links. You can download the PDF for more details or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Stock shortages are a serious issue faced by many companies. When appropriate inventory levels cannot be maintained, there is a risk of missing sales opportunities and decreasing customer satisfaction. Furthermore, response costs may increase, and there is also the possibility of holding excess inventory. This article will explain the definition and impact of stock shortages in detail, as well as introduce numerical indicators and calculation methods for inventory management. *For more details, you can view the related links. Please feel free to download the PDF or contact us for more information.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"Sales forecasting" is a key factor that influences business success. By understanding its importance and using appropriate calculation methods, companies can achieve more efficient inventory management and optimize their resources. However, accurately forecasting sales is not easy. This article will provide a detailed explanation of the basic concepts of sales forecasting, how to choose calculation methods, and specific ways to improve accuracy. *For more details, you can view the related links. For further information, please download the PDF or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

It is often said that "when inventory increases, profits increase," but is that really the case? In the manufacturing industry, it is important to pay attention to the impact of inventory on accounting profits. The phenomenon of "increasing inventory leading to increased profits" is related to accounting mechanisms and can lead to erroneous management decisions. This article will explain the issue of excess inventory in the manufacturing industry, its solutions, and the mechanisms by which increasing inventory can lead to increased profits. *For more detailed information, please refer to the related links. You can download the PDF for more details or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Reducing inventory in the manufacturing industry is not just about cutting costs; it is a management challenge that directly relates to improving turnover rates, reducing stockout rates, and ensuring healthy cash flow. Especially in recent years, as uncertainty in the supply chain has increased, it has become more important to accurately manage "when and how much to order" rather than "how much inventory to hold." This article will explain the basic steps to advance inventory reduction in manufacturing, as well as specific methods such as setting safety stock levels, designing reorder points, and optimizing order quantities. *For more detailed content, please refer to the related links. For further information, feel free to download the PDF or contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

To manage inventory properly, it is important to accurately forecast the demand for products. As consumer needs diversify and the pace of change increases, making inventory forecasts and maintaining appropriate inventory levels is not easy. Excess inventory incurs additional costs, while shortages can lead to missed sales opportunities. Against this backdrop, it becomes crucial to conduct proper inventory and demand forecasting. Demand forecasting is a strategic means of maintaining optimal inventory levels by analyzing past data and market trends to predict future demand. By carrying out this process correctly, companies can reduce waste in inventory and achieve efficient resource allocation. In this article, we will explain the overview and importance of demand forecasting in inventory management, specific methods, and case studies. *For more detailed content of the blog, please refer to the related links. For further information, you can download the PDF or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Demand forecasting refers to the process of predicting the sales and customer numbers of a company's products and services. Companies utilize this forecast to aid in inventory management, production planning, and the formulation of marketing strategies. Since demand fluctuates based on market and consumer trends, accurate forecasting is key to enhancing a company's competitiveness. This article will provide a detailed explanation of the fundamental concepts of demand forecasting, the challenges faced and their solutions, as well as points for improving accuracy and trends in the latest technologies. *For more details, you can view the related links. For further information, please download the PDF or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In industries such as wholesale, retail, and manufacturing, businesses that handle products as inventory often face challenges like "increasing leftover stock" and "how to avoid holding excessive inventory." The idea of "keeping a little extra inventory just in case" seems quite normal for companies involved in inventory management. However, holding too much inventory is referred to as "excess inventory," which can lead to many risks and disadvantages. This article will explain the risks associated with excess inventory and methods to reduce it. *For more detailed information, please refer to the related links. You can download the PDF for more details or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The evolution of IT has particularly drawn attention to AI technology in recent years. This article will explain the basic knowledge of demand forecasting using AI, the social background that is attracting attention, the advantages and disadvantages of its use, specific implementation steps, and case studies. *You can view the detailed content of the blog through the related links. For more information, please download the PDF or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Demand forecasting refers to predicting various "quantities of demand," such as product sales and the number of items needed for procurement. This article will clearly explain the basics of demand forecasting, specific methods, and approaches that utilize the latest technologies. *For detailed content of the blog, you can view it through the related links. For more information, please download the PDF or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Demand forecasting systems support the optimization of inventory management, production planning, and marketing strategies by predicting future demand based on past data. In particular, those utilizing AI are becoming essential tools for many companies due to their high accuracy and rapid analysis capabilities. This article will provide a detailed explanation of the fundamentals of demand forecasting systems, specific use cases, the benefits of implementation, and recommended systems. *For more detailed content of the blog, please refer to the related links. For more information, you can download the PDF or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

For companies that engage in inventory management, the challenge is how to reduce inventory. This article will introduce the purpose of inventory reduction, specific methods for achieving it, and examples of successful reductions. *You can view the detailed content of the blog through the related links. For more information, please download the PDF or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Excess inventory refers to stock that remains in a warehouse without being sold or shipped for a certain period after purchase. Many company representatives may want to understand the management risks associated with holding excessive inventory in advance or are struggling with inventory management methods. This article focuses on excess inventory, explaining the differences between excess inventory, surplus inventory, and defective inventory, the causes of increasing excess inventory, and how to address it. *For more detailed information, you can view it through the related links. For more details, please download the PDF or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Sales forecasting refers to predicting a company's future sales revenue, and accurately forecasting sales can lead to optimizing inventory and personnel allocation. Among those in retail and manufacturing, there may be individuals who wish to improve the accuracy of their sales forecasts. In this article, we will explain the importance of sales forecasting, how to calculate it, and methods to enhance forecasting accuracy. *For more detailed information, you can view the related links. For further details, please download the PDF or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We often hear concerns from companies where inventory management is essential, such as regular occurrences of stockouts and difficulties in reducing the stockout rate. In this article, we will explain the basic concepts of stockout rates and how to solve and improve this issue, incorporating specific methods and tools. *For detailed content of the blog, you can view it through the related links. For more information, please download the PDF or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Excess inventory refers to a situation where the stock held exceeds the demand for the products. Holding more inventory than necessary increases inventory costs and can lead to an increase in obsolete stock and a deterioration of cash flow. Some individuals in retail and manufacturing may be struggling with the thought, "I want to address excess inventory, but I don't know how to optimize it." This article will explain the causes, disadvantages, risks, and countermeasures related to excess inventory. *For more details, you can view the related links. For further information, please download the PDF or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the manufacturing industry, maintaining optimal inventory levels is a crucial issue that directly impacts performance. This article explains the calculation methods for maintaining optimal inventory levels and specific methods to achieve them. *For more detailed information, you can view it through the related links. For further details, please download the PDF or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In industries and business types where inventory management operations occur, how to maintain optimal inventory levels and maximize corporate profits without causing excess or stockouts is a significant challenge. This article will explain the basic concepts for maintaining optimal inventory, methods for calculating optimal inventory, and management techniques. *For detailed content of the blog, you can view it through the related links. For more information, please download the PDF or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

By optimizing inventory, benefits such as optimizing cash flow, reducing excess inventory, preventing stockouts, and maintaining product quality can be achieved. However, many people in retail and manufacturing may wonder, "How can I optimize inventory?" In this article, we will explain the benefits of inventory optimization, traditional methods and challenges of inventory optimization, and options for demand forecasting in inventory optimization. *For more detailed information, please refer to the related links. For further details, you can download the PDF or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In companies where inventory management operations occur, accurate inventory forecasting is required. However, achieving accurate inventory forecasts is very challenging, and it is not uncommon to struggle with excess inventory or stock shortages. Additionally, the burden on the personnel responsible for inventory forecasting is also a significant issue. This article will explain the challenges of inventory forecasting operations and discuss the introduction of demand forecasting AI as a method to solve these challenges. *For more detailed information, you can view the related links. For further details, please download the PDF or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Efficient inventory management significantly affects a company's profitability and management situation. Additionally, by maintaining appropriate inventory levels, companies can quickly respond to customer demand, leading to increased satisfaction. On the other hand, excessive inventory can increase costs and pose risks to cash flow liquidity. This article will provide a detailed explanation of the advantages and disadvantages of holding inventory, as well as the associated risks and how to address them. We will also introduce the latest AI tools that can be utilized to enhance the accuracy of demand forecasting. In particular, no-code AI tools are recommended for many companies as they can be implemented without technical knowledge. *For more detailed information, please refer to the related links. For further inquiries, feel free to download the PDF or contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Demand forecasting is the process of predicting how much of a product will sell (whether there is demand for it). To maximize sales opportunities and optimize inventory, accurate demand forecasting is essential. However, some individuals in retail and manufacturing may struggle with issues such as "not being able to accurately forecast demand for new products" or "experiencing significant fluctuations in product sales due to seasonal changes." This article will provide a detailed explanation of the basic concepts of demand forecasting, its benefits, the necessary data, and actual case studies of its application. *For more detailed content, please refer to the related links. For further information, feel free to download the PDF or contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Inventory optimization is essential for properly managing stock and minimizing excess and shortages. This article will explain the overview and methods of inventory optimization. *You can view the detailed content of the blog through the related links. For more information, please download the PDF or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

There are various methods and tools for inventory forecasting, each with its own advantages and disadvantages. This article will provide a detailed explanation of the basics of inventory forecasting, as well as specific methods using Excel. Excel is widely used as a tool for inventory forecasting in many companies due to its flexibility and ease of use. Additionally, there are several other options available for demand forecasting, which will also be introduced. Inventory forecasting is a crucial element for enhancing the operational efficiency of a business. Please refer to this article to choose the appropriate methods and tools, aiming for the optimization of inventory management. *You can view the detailed content of the blog through the related links. For more information, please download the PDF or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Cycle inventory refers to the stock that is consumed within a certain period to meet normal demand. This article will provide a detailed explanation of the basic concepts and definitions of cycle inventory, how to determine the appropriate quantity, calculation methods, management techniques, roles by industry, and even forecasting methods. Through this article, we aim to deepen your foundational knowledge of cycle inventory and equip you with practical management methods. *For more detailed content of the blog, you can view it through the related links. For more information, please download the PDF or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Inventory management costs refer to the total expenses incurred from holding inventory, which include various items such as warehouse rent, utility costs, labor costs, storage fees, and transportation costs. Among those in the manufacturing industry, there may be individuals who think, "The burden of inventory management costs is significant, so I want to reduce them." In this article, we will explain the overview of inventory management costs, methods for reduction, and important aspects such as demand forecasting that are crucial for cost reduction. This article will also help you understand tools that are useful for efficient demand forecasting, so please read it to the end. *For more detailed information, you can view it through the related links. For more details, please download the PDF or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Demand forecasting refers to predicting future expectations regarding sales and customer numbers, and in the manufacturing industry, demand forecasting using AI is also being implemented. This article explains the necessity and benefits of demand forecasting in the manufacturing industry, the steps for implementing AI, and case studies. It is an article that helps you understand the image of implementing demand forecasting using AI and the steps involved, so please read it through to the end. *For more detailed content of the blog, you can view it through the related links. For more information, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Excess inventory refers to a situation where the amount of goods stored in a warehouse significantly exceeds market demand. This issue poses various risks and disadvantages for companies, often necessitating a review of countermeasures. This article provides a detailed explanation of the causes of excess inventory, its risks, and specific countermeasures. By understanding specific countermeasures for excess inventory, companies can achieve more efficient inventory management, reduce unnecessary costs, and enhance customer satisfaction. If you are feeling challenges with current excess inventory measures, please read to the end. *For more detailed content of the blog, you can view it through the related links. For more information, please download the PDF or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Many people may want to know how to effectively utilize AI for demand forecasting, along with specific examples. In this article, we will introduce eight examples of demand forecasting using AI and provide a detailed explanation of the methods and benefits. For companies looking to improve the accuracy of their demand forecasts and enhance operational efficiency, the implementation of AI can be a significant help. By reading this article, you will understand how AI performs demand forecasting and what benefits it brings. Furthermore, through specific examples, you can confirm how practical the use of AI can be. *For more detailed content of the blog, you can view it through the related links. For more information, please download the PDF or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration