1~10 item / All 10 items

Displayed results

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Contact this company

Contact Us Online1~10 item / All 10 items

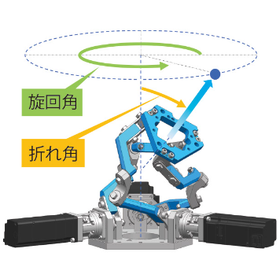

The wrist joint module "i-WRIST(R)" is a positioning module that enables high-speed and smooth movement. With direct teaching, programming is unnecessary, allowing for easy teaching while moving it directly. By attaching cameras, lighting, dispensers, cleaning nozzles, and more, it enables the automation and labor-saving of various processes such as visual inspection, grease application, and cleaning. 【Features】 ■ Maximum payload is 3kg ■ Supports various mounting methods including upward, downward, and sideways ■ No singularities, allowing for operation without worrying about twisting of wiring cables As the use of robots is advancing in manufacturing sites to further improve productivity and reduce labor, the wrist joint module "i-WRIST" contributes to the automation and labor-saving in manufacturing environments.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The wrist joint module "i-WRIST" can quickly transform into various devices by attaching an end effector to its tip or combining it with other robots. It is equipped with a dispenser, allowing for high-speed application of liquids to targeted positions from multiple directions. Additionally, it can be equipped with cameras and lighting for visual inspection, enabling high-speed imaging of complex-shaped workpieces from various angles. 【Case Overview】 ■ Liquid application (grease, adhesive): Equipped with a dispenser ■ Cleaning: Equipped with a cleaning nozzle ■ Visual inspection: Equipped with cameras and lighting ■ Assembly: Equipped with a gripper *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce the features of the latest version of our wrist joint module, 'i-WRIST.' The installation direction can accommodate not only downward but also upward, sideways, and inclined orientations. In addition to the conventional parallel input/output (I/O), the external communication interface now supports the industrial network "Ethernet," increasing the amount of communicable information. Furthermore, it complies with the safety standard ISO10218-1 for industrial robots, and the maximum command speed has been improved by 1.6 times compared to the previous version, achieving even greater speed. 【Features】 ■ Supports upward, sideways, and inclined orientations ■ Compatible with the industrial network "Ethernet" ■ Complies with safety standard ISO10218-1 ■ Maximum command speed improved by 1.6 times compared to the previous version *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

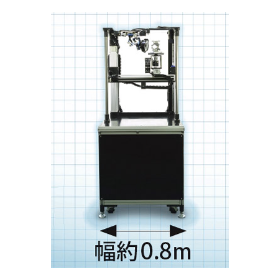

Until now, factories that had given up on installing automation equipment due to space constraints can now do so with our 'i-WRIST.' This product features a compact design with a width of approximately 0.8m. By combining it with linear actuators and rotary actuators, it can be installed in about half the space required for conventional appearance inspection devices using typical robots. It addresses the challenge of wanting to introduce automated equipment for labor-saving purposes, but finding it difficult to install due to the size of robot-based systems. 【Specifications (partial)】 ■ Height: Approximately 2m ■ Width: Approximately 0.8m ■ Depth: Approximately 0.85m *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our 'i-WRIST' can solve issues such as 'the programming language for robots is difficult, and I can hardly master it' and 'it takes time when it comes to education.' To operate a typical robot, a dedicated programming language was necessary, but our product does not require any programming language at all. You can easily perform teaching just by operating the dedicated console screen, and we also provide software that allows you to efficiently create motion patterns on your computer. [Features] ■ No programming language required for operation ■ Easy operation with a dedicated console ■ Even easier with point data editing software *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"We introduced a robot, but it doesn't meet the target takt time. In the end, humans are faster and more convenient." This issue can be resolved with our 'i-WRIST'. The high speed of this product is particularly effective when approaching the workpiece from multiple directions. Even takt times that are difficult for conventional robots can be achieved. Please feel free to contact us when you need assistance. [Overview] ■Comparison of movements approaching four points - A movement that takes 4 seconds with a typical robot can be achieved in less than half the time, at 1.4 seconds. ■Comparison of movements approaching the workpiece from multiple directions - A movement that takes 15 seconds with a typical robot can be achieved in less than half the time, at 7.5 seconds, with our product plus an electric actuator. *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "i-WRIST(R)" is a module for robots that performs high-speed positioning. The movement achieved by its unique drive mechanism is as flexible as a human wrist and features a compact design. When equipped with a camera, it can be used for visual inspection of complex-shaped workpieces, and when equipped with a dispenser, it can apply grease from multiple directions, making it suitable for a wide range of applications. Moreover, it can achieve tact times that are difficult for conventional robots, such as vertical multi-joint robots. 【Features】 ■ High-speed operation ■ Wide range of motion ■ Compact design *For more details, please download the PDF or contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce the features of our wrist joint module, 'i-WRIST'. It achieves a tact time that was difficult for general robots, such as multi-joint robots, and can be easily operated by anyone without the need for programming languages. Additionally, it can be installed in factories that had previously given up on automation equipment. Equipped with a camera, it can perform appearance inspections of complex-shaped workpieces, and with a dispenser, it can apply grease from multiple directions, making it suitable for a wide range of applications. 【Three Features】 ■ High Speed ■ Ease of Operation ■ Space Saving *For more details, please refer to the related links or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We have started proposing a "fine coating device with measurement function" that adds a "fine three-dimensional shape measurement" function to our "desktop high-speed fine coating device," which can accurately apply tiny droplets of a few picoliters (pl) attached to the tip of a needle in 0.1 seconds per application. By measuring the three-dimensional shape of the applied material immediately after coating, we can calculate the coating area and the volume of the applied material, enabling quality control. Additionally, it is possible to add a function for adjusting the coating amount based on trend management from the measurement results of each coating process. 【Features】 ■ Shape measurement and inspection immediately after high-speed fine coating ・High productivity in coating and quality control ■ Measurement of coating shape, area, and volume of applied material ・Monitoring of time-dependent changes in the coating material and evaluation of properties such as drying performance *For more details, please refer to the related links or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Contributing to the resolution of such issues: 1. I want to apply a very small amount of liquid, but it cannot be applied using a dispenser method. 2. I want to apply a high-viscosity liquid, but it cannot be applied using an inkjet method due to clogging. 3. I want to apply a high-viscosity liquid in a very small amount at high speed. 4. I want to improve application accuracy. Features of the NTN fine coating device: 1. Capable of applying a very small amount of liquid in the range of a few picoliters. 2. Capable of applying high-viscosity liquids up to 100 Pa·s. 3. High-speed application at 0.15 seconds per application. 4. Repetition accuracy of ±15 μm or less. 5. Easy replacement of ink tanks. 6. Easy application with mouse operation. Applicable fields and examples of liquids: ■ Electronic component mounting: Application of adhesives and conductive pastes. ■ Bio and new drug development: Spotting of very small amounts of reagents, etc. ■ High-density wiring for substrates: Electrode connections using conductive paste application. ■ Assembly processes: Adhesives. The NTN fine coating device contributes to improving the productivity of customers considering fine and high-speed coating. *For more details, please refer to the related links or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration