1~20 item / All 20 items

Displayed results

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Contact this company

Contact Us Online1~20 item / All 20 items

When searching for the terms "smart factory" or "smart factory," explanatory articles such as "What is a smart factory?" still rank highly. In fact, when speaking with those in the manufacturing industry, it is not uncommon to encounter the question, "What exactly is a smart factory?" As for examples from other companies or those that have made early investments, most often they are introductions to tools and solutions, making it difficult to use them as references for one's own company. Our partner company, the Smart Factory Research Institute, believes that to realize a "smart factory," it is essential to have a perspective that emphasizes "practical ideas and approaches for becoming a smart factory" and "initiatives that create management effects across the entire company, rather than just individual process efforts." They have been selecting case studies from this perspective and hosting a series of seminars. Until February 3, 2023, they will be offering on-demand streaming of the past two sessions for a limited time. We encourage you to take this opportunity to watch!

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The Smart Factory Research Institute plans to hold a seminar in collaboration with a leading expert in management engineering from Keio University, featuring advanced smart factories in Japan, scheduled to take place bi-monthly in the future. Our company will also introduce AI/IoT topics as a partner company. Seminars that specifically showcase successful cases of smart factories in Japan are rare, so this is a must-see and must-hear event! We sincerely look forward to your participation in this opportunity. 【Seminar Overview】 ■ Free Online Seminar: This is Japan's Smart Factory - Case Study Series ■ Organized by: Smart Factory Research Institute Co., Ltd. ■ Date and Time: June 23, 2022 (Thursday) 16:00 - 17:30 *For more details, please refer to the PDF document or feel free to contact us. Inquiries will be handled by the "Smart Factory Research Institute."

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company will hold an online seminar titled "Beyond Data Analysis: Realizing Decision-Making and Planning" on Wednesday, June 8, 2022. Mathematical optimization is a problem-solving tool that enables decision-making and planning based on the results of data analysis. However, having specialized knowledge does not mean that real-world problems can be solved immediately. In reality, there are numerous challenges from modeling optimization problems to system implementation. In this seminar, we will welcome Professor Toshiharu Umetani from Osaka University’s Mathematical Optimization Chair, who will explain the challenges and countermeasures that arise when tackling real-world problems using mathematical optimization. This seminar is highly recommended for companies facing challenges in supporting production planning and decision-making, which tend to become personalized. [Overview] ■ Date and Time: June 8, 2022 (Wednesday) 16:30 - 17:45 ■ Agenda (1) Lecture by Professor Umetani... 60 minutes (2) Introduction of IPS services... 5 minutes (3) Q&A... 10 minutes *If you wish to participate, please apply from "Click here to register for the seminar." We look forward to your participation.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company will hold an online seminar titled "AI, IoT, DX... When You're Struggling with Funding for Technology Investments - The Right Way to Utilize Subsidies" on Thursday, May 26, 2022. When we ask about the factors hindering DX promotion, the keywords that always come up are "human resources" and "funding." This seminar will focus on the "funding" aspect, which is one of these two major hindrances. Mr. Murao, a small and medium-sized enterprise consultant, will introduce several subsidies that are easy for manufacturing companies to utilize, along with tips for successful applications. [Overview] ■ Date and Time: Thursday, May 26, 2022, 16:30–17:30 ■ Agenda (please refer to the catalog for details) (1) Mr. Murao's lecture... 45 minutes (2) Explanation of services provided by IPS... 5 minutes (3) Q&A... 10 minutes *If you wish to participate, please apply through "Click here to register for the seminar." We look forward to your participation.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company will hold an online seminar on "Three-Dimensional Appearance Inspection Using Illumination Difference Stereo Method" on Tuesday, May 17, 2022. One common application of image recognition technology in the manufacturing industry is appearance inspection. This task is still largely performed visually by humans, and we often hear requests to improve accuracy and reduce labor. In this seminar, we will provide practical explanations with specific examples, so companies facing challenges in appearance inspection are encouraged to participate. 【Overview】 ■ Date and Time: Tuesday, May 17, 2022, 16:30 - 17:30 ■ Instructor: Professor Yasuyuki Matsushita, Graduate School of Information Science, Osaka University ■ Agenda (1) Lecture by Professor Matsushita…45 minutes - Various three-dimensional shape estimation techniques - What is the illumination difference stereo method? - Specific examples applying the illumination difference stereo method (2) Introduction of IPS case studies…5 minutes (3) Q&A session…10 minutes *If you wish to participate, please apply through "Click here to register for the seminar." We look forward to your participation.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company will hold an online seminar titled "What is Lacking in Today's Smart Factories" on April 27, 2022 (Wednesday). *Please note that the seminar has concluded successfully. In this seminar, Professor Hiroaki Matsukawa from Keio University, Department of Management Engineering, will give a lecture incorporating keywords such as "automation," "informationization," "intelligence," "synchronization," "autonomy," and "optimization," discussing what is lacking. What exactly is a smart factory? If you are interested in exploring its essence, please do not miss this opportunity. [Overview] ■ Date and Time: April 27, 2022 (Wednesday) 16:30–17:30 ■ Agenda (1) Lecture by Professor Matsukawa…45 minutes - What is lacking in today's smart factories (from an academic perspective) - What is lacking in today's smart factories (from a business process perspective) (2) Explanation of services provided by IPS…5 minutes (3) Q&A session…10 minutes *Please note that the seminar has concluded successfully. Thank you very much for your participation.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company will be presenting a seminar at the "INTERMOLD Mold Exhibition and Metal Press Processing Technology Exhibition" held at Intex Osaka from April 20 (Wednesday) to April 23 (Saturday), 2022. The seminar is titled "What Preparations Should You Start Right Now for DX in Manufacturing and Smart Factories?" We often hear voices like, "Where should I start? The results aren't what I expected!" regarding smart factories, which are at the core of DX. This presentation will offer insights from the perspective of an IT company well-versed in data on "What is a smart factory? What should we tackle first?" We sincerely look forward to your attendance. [Presentation] ■ April 20 (Wednesday) 13:00 - 14:00 ■ "What Preparations Should You Start Right Now for DX in Manufacturing and Smart Factories?" ■ Hideki Matsumoto, Sales Planning Manager, Business Development Department, IPS Corporation *For more details, please refer to the related link or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

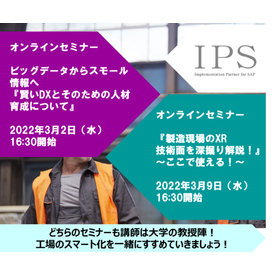

Our company is starting initiatives to support the construction of smart factories as the digital transformation (DX) becomes more established. We will hold a free seminar where experts will explain themes that those in the manufacturing industry working on smart factories may be interested in! 【Overview of the Online Seminar】 ■ Instructor: Associate Professor Ryo Zhao, Graduate School of Advanced Integrated Studies in Human Survivability, Kyoto University ■ Theme 1: "Smart DX and Human Resource Development for It" This will provide hints for those who feel challenges regarding human resource development and recruitment. ■ Date and Time: March 2, 2022 (Wednesday) 16:30 - 17:30 ■ Instructor: Professor Masataka Imura, Department of Intelligent and Mechanical Engineering, Kansai Gakuin University ■ Theme 2: "In-depth Explanation of XR Technology in Manufacturing Sites!" This topic is perfect for those who think XR technology could be utilized in manufacturing but struggle to envision specific applications. ■ Date and Time: March 9, 2022 (Wednesday) 16:30 - 17:30 *If you wish to participate, please apply from "Click here to register for the seminar." We look forward to your participation.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

IPS will hold an online seminar titled "Latest Trends in Image Sensing and Image Recognition Technologies for Smart Factories" on December 16, 2021 (Thursday). *The seminar has concluded successfully. In recent years, the utilization of image sensing and image recognition technologies has been actively promoted. To put these technologies into practical use, there are important points that must not be overlooked. Incorporating new technological trends, we will have a lecture by Professor Matsushita from Osaka University Graduate School, who is our special advisor, focusing on perspectives that private companies often overlook. We encourage companies considering image sensing and image recognition, as well as those dissatisfied with their past results, to participate. This is the first and last chance in 2021 to hear from the authority in the field, Professor Matsushita. [Overview] ■ Date and Time: December 16, 2021 (Thursday) 16:30 - 17:30 ■ Seminar Content - Lecture by Professor Matsushita (45 minutes) - Q&A (5-10 minutes) - Introduction of our case studies (5-10 minutes) *The seminar has concluded successfully. Thank you very much for your participation.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Depending on the nature and size of the raw materials, fine adjustments may be necessary in the manufacturing process. I believe that these fine adjustments have relied on the "craftsman's intuition," but in today's world, where securing skilled personnel is difficult, let's visualize (data-ify) the "craftsman's intuition" and evolve it into a task that anyone can handle. By utilizing "image recognition AI," we can detect the size of raw materials falling at high speed and measure the distribution by size. By taking into account data (parameters) that are factors other than size, which determines quality, we can adjust the equipment, marking the first step towards automated operation using deep learning AI. Please feel free to contact us when needed. 【Use Case】 ■ Measuring the distribution of falling raw materials by size *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The core system "SAP ERP" enables daily financial closing. Anyone, anytime, anywhere can see the company's "now," and the transparency is supported by data input. However, inputting actual results in manufacturing sites can often become a batch process. Especially in overseas factories, we often hear concerns about input errors. Our 'AI-OCR,' developed for our customers, has solved this issue. 【Features】 ■ Paper documents - Accuracy of over 99% - Reduces working time by up to 75% ■ Output files - Can read both printed and handwritten parts ■ Further automation is possible when used in conjunction with RPA *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

IPS, which has a proven track record of making the core system 'SAP ERP' accessible to mid-sized companies, can explain the concept of smart factories. There are limits to what you can achieve on your own. Please leverage the knowledge of IT companies for IT matters. Let's start by "knowing." Just like with new equipment, why not hold study sessions within your company to alleviate vague feelings of anxiety? 【Overview】 ■ Duration: 1-2 hours ■ Location: Online ■ Contents - What is happening in the manufacturing industry now / What is a smart factory / How to promote smart factories ■ Cost: Free *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This document introduces a survey on the systematization of production planning and inventory planning in the manufacturing industry, as well as the utilization of AI. It includes tables and graphs detailing "challenges," "current systems," "budget considerations," and "interest in AI" categorized by company size (number of employees). Please feel free to download and take a look. 【Contents (excerpt)】 ■Survey Overview ■Challenges Related to Demand Forecasting ■Investment Budget and Implementation Timing for Current Systems ■Intent to Utilize AI for Demand Forecasting ■Challenges in Promoting DX *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

IPS Corporation will hold a DX promotion event titled "D×" on Thursday, July 15, 2021, featuring an event by the Osaka DX Promotion Partners called "Let's Start Here! - The First Step to a 'Smart Factory'". What exactly is a "smart factory"? Where should one begin? We will clearly explain the points and considerations for Japanese manufacturing, especially for small and medium-sized enterprises, when tackling "smart factories". For more details, please see the link below. We look forward to your participation. 【Seminar Overview】 ■ Date: Thursday, July 15, 2021, 15:00 - 16:00 ■ Location: Online ■ Target Solution: Smart Factory *For more details, please refer to the related link page or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

IPS Corporation will hold an online seminar titled "Steps and Challenges of Smart Factory Implementation in Medium and Small Enterprises" on Tuesday, July 27, 2021. The representative example of DX in manufacturing is "smart factories." However, there are few successful cases that can serve as models for medium and small enterprises. In this seminar, we will discuss what the challenges are and in what order to proceed. You can register via the link below. We look forward to your participation. 【Seminar Overview】 ■ Speaker: IPS Corporation ■ Date and Time: Tuesday, July 27, 2021, 16:00 - 16:45 ■ Venue: Online (You can participate from your computer, smartphone, or tablet) ■ Target Audience: Those considering smart factory implementation ■ Participation Fee: Free *For more details, please refer to the related link page or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Digital transformation is fundamentally changing the entire business by leveraging data and digital technologies. Japanese companies have historically been more eager to take on new challenges. Let's start together! We aspire to be a vendor that provides consulting services that allow our customers to begin more easily. Please feel free to contact us. ■ We will work closely with our customers and start together, launching the business from the point where we both feel it is likely to succeed. ■ It is a waste of time for both parties to get caught up in too much talk about "PoC" or "contracts" without actually starting, so our motto is quick start. ■ Based on our extensive experience in implementing core business systems like SAP, we can offer proposals that consider overall optimization. *For more details, please refer to the related links page or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Smart factories are not something special. They are an extension of the existing QCD. That is why the realization of "visualization" is important first. It is essential to design a database and to collect the necessary information as easily as possible. Simply adding sensors and introducing the latest equipment is not enough. Let's move forward with our goals in mind! *For more details, please refer to the related link page or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Traceability is an essential requirement, especially for transactions with overseas companies, depending on the industry. It is precisely because we at IPS are well-versed in SAP ERP, the epitome of "visualization," that we can build systems that are accurate and faster! Let’s think together about a grounded system, not a grand dream story. Please feel free to contact us when you need assistance. *For more details, please refer to the related links page or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The initial consultation brought in was about the low accuracy of monthly sales forecasts prepared by the sales team, which resulted in frequent stockouts. We proposed calculating the standard inventory and safety stock based on sales forecasts and forecast accuracy, and conducting planned production based on the derived production quantities. It is important not only to predict demand but also to change inventory management methods and production planning approaches. We will support you in considering how to hold standard inventory based on sales rank and forecast accuracy, and reflecting this in your production plans. 【Features】 1. Daily data is decomposed into four components: "trend," "weekly seasonality," "annual seasonality," and "monthly seasonality" (additional factors for holidays and events can be included). 2. An error term is added to the elements from step 1, combined linearly to create a forecasting model. 3. The model's output is aggregated monthly. * This will serve as an example of forecasting on a monthly basis using item-specific and daily sales data. * For more details, please refer to the related link page or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

First, we will provide the daily and item-specific sales data that is the subject of the issue, conduct forecasts using the IPS demand forecasting program, and analyze the discrepancy between the forecasted values and the actual values as the forecast error to verify and analyze the level of accuracy achieved. Next, we will analyze the trends in the discrepancies between the output forecasted values and actual values, and set the goals and KPIs that should be achieved in this initiative. Finally, we will modify the forecasting program to match the sales trends of the customer's items. 【Approach to Demand Forecasting】 1. Simple analysis using the demand forecasting AI (prototype) 2. Accuracy trend analysis and setting of goals and KPIs for each item 3. Program modifications for accuracy improvement for each customer 4. Achievement of goals and KPIs *For more details, please refer to the related link page or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration