1~21 item / All 21 items

Filter by category

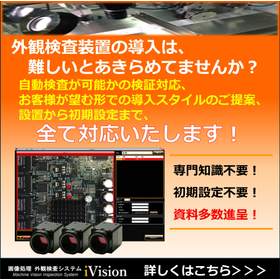

Image Processing Appearance Inspection System "iVision"

"The Reiwa era is the age of machine vision!" Quality demands for various products are increasing year by year. Considering customer safety and corporate credibility, the response from manufacturers is unavoidable, but the harsh reality of quality inspection is that it cannot generate profit even with increased manpower. Companies wish to "reduce manpower while improving quality accuracy." AdD offers timely proposals for such production and quality environments. With nearly 200 verification achievements annually across various fields, proposals for cost-effective inspection systems, and customization to meet customer needs, we aim to provide satisfaction. "AdD is creating the future of machine vision." Can we have a conversation? *Please select case studies from the top page for various implementation examples and styles by item.