1~45 item / All 200 items

Displayed results

Filter by category

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Contact this company

Inquiry FormBefore making an inquiry

Download Profile1~45 item / All 200 items

Filter by category

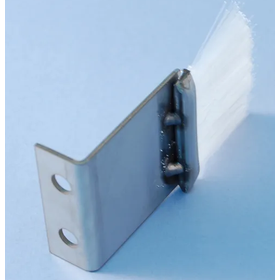

Our company manufactures and sells custom industrial brushes with short lead times, starting from a single unit. We welcome consultations regarding your desired bristle materials and shapes, and after hearing about your challenges, we also propose brushes suitable for your specific needs. Here, we introduce a case where a straight brush made with nylon bristles has an L-shaped metal fitting welded onto it. We can accommodate various shapes in our custom orders. We are currently offering two explanatory materials from brush professionals! "How to Properly Select Bristle Materials for Industrial Brushes (with Chart)" "Solving On-Site 'Problems' with Brushes! Technical Proposal Case Studies" Please take a look from the <Catalog Download>. *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company manufactures and sells custom industrial brushes with short lead times, starting from a single unit. You can consult us about your desired bristle materials and shapes, and after hearing about your concerns, we will also propose brushes suitable for your specific application. Here, we introduce a case using Thunderon for the bristles and SUS for the fittings, ideal for sweeping fine dust affected by static electricity. We are currently offering two explanatory documents by brush professionals! "How to Properly Select Bristle Materials for Industrial Brushes (with Chart)" "Solving On-Site 'Problems' with Brushes! Technical Proposal Case Studies" Please check them out from the "Catalog Download" section. *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

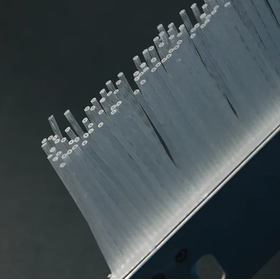

Our company manufactures and sells custom industrial brushes with short lead times, starting from a single unit. We welcome consultations regarding your desired bristle materials and shapes, and after hearing about your challenges, we can also propose brushes suitable for your specific needs. Here, we introduce an example of a brush made with the thickest bristle material, which is 2mm in diameter PP. However, due to the thickness of the bristle material, there are some channel sizes that cannot be produced. Typically, thick PP bristles tend to be flat due to manufacturing issues, but our thick PP bristles are round thanks to the ingenuity of the bristle material manufacturer. We are currently offering two explanatory materials from brush professionals! "How to Properly Select Bristle Materials for Industrial Brushes (with Chart)" "Solving On-Site 'Problems' with Brushes! Technical Proposal Case Studies" Please take a look at them from the <Catalog Download>. *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

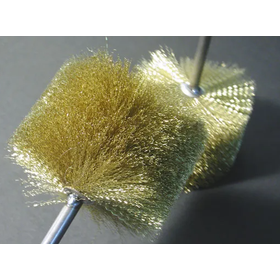

Our company manufactures and sells custom industrial brushes with short lead times, starting from a single unit. We welcome consultations regarding your desired bristle materials and shapes, and after hearing about your challenges, we can also propose brushes suitable for your specific needs. Here, we would like to introduce examples of custom straight brushes that are unique to made-to-order products. This is made with brass bristles. The metal fittings have been creatively processed to form a figure-eight shape. It is also possible to create combinations. We are currently offering two explanatory materials from brush professionals! "How to Properly Select Bristle Materials for Industrial Brushes (with Chart)" "Solving On-Site 'Problems' with Brushes! Technical Proposal Case Studies" Please take a look at them from the <Catalog Download>. *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company manufactures and sells custom industrial brushes with short lead times, starting from a single unit. Of course, we welcome consultations regarding your desired materials and shapes, and after hearing about your challenges, we also offer suggestions for brushes suitable for your specific needs. Here, we would like to introduce an example of a goat hair brush designed to remove fine dust. Can you feel the soft texture? We are currently offering two explanatory materials from brush professionals! "How to Properly Choose Materials for Industrial Brushes (with Chart)" "Solving On-Site 'Problems' with Brushes! Technical Proposal Case Studies" Please take a look from the <Catalog Download>. *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company manufactures and sells custom industrial brushes with short lead times, starting from a single unit. Of course, you can consult us about your desired bristle materials and shapes, and after hearing about your challenges, we will also propose brushes suitable for your specific needs. Here, we introduce examples of brushes made with nylon containing abrasive particles, which are also used for wood grain finishing. We are currently offering two explanatory materials from brush professionals! "How to Properly Select Bristle Materials for Industrial Brushes (with Chart)" "Solving On-Site 'Problems' with Brushes! Technical Proposal Case Studies" Please take a look at them from the <Catalog Download>. *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company manufactures and sells custom industrial brushes with short lead times, starting from a single unit. You can consult us about your desired bristle material and shape, and after hearing about your challenges, we will also propose brushes suitable for your specific needs. Here, we would like to introduce an example of a wire roll brush with a screw. The shaft is threaded to allow connection to equipment. We are currently offering two explanatory materials from brush professionals! "How to Properly Select Bristle Materials for Industrial Brushes (with Chart)" "Solving On-Site 'Problems' with Brushes! Technical Proposal Case Studies" Please take a look at them from the <Catalog Download>. *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

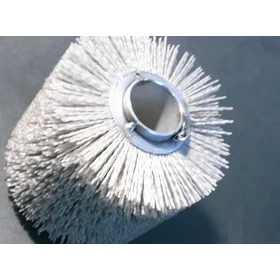

Our company manufactures and sells custom industrial brushes with short lead times, starting from a single unit. You can consult us about your desired bristle materials and shapes, and after hearing about your challenges, we will also propose brushes suitable for your specific needs. Here, we would like to introduce an example of a roll brush made for a single rotation. We manufacture everything in-house, from the fittings to the final product. We are currently offering two explanatory documents by brush professionals! "How to Properly Choose Bristle Materials for Industrial Brushes (with Chart)" "Solving On-Site 'Problems' with Brushes! Technical Proposal Case Studies" Please check them out via the "Catalog Download." *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company manufactures and sells custom industrial brushes with short lead times, starting from a single unit. Of course, we welcome consultations regarding your desired bristle materials and shapes, and after hearing about your challenges, we also provide suggestions for brushes suitable for your specific needs. Here, we introduce a case where a brass brush with a diameter of 0.06 was wrapped around a shaft with a diameter of 6 mm. Although the shaft is thin, the fine diameter of the bristle material results in a dense bristle tip. We are currently offering two explanatory materials from brush experts! "How to Properly Select Bristle Materials for Industrial Brushes (with Chart)" "Solving On-Site 'Problems' with Brushes! Technical Proposal Case Collection" Please take a look at them from the <Catalog Download>. *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company manufactures and sells custom industrial brushes with short lead times, starting from a single unit. Of course, you can consult us about your desired bristle materials and shapes, and after hearing about your challenges, we will also propose brushes suitable for your specific needs. Here, we would like to introduce an example of a roll brush with a stepped shaft and SW0.4 bristles. It is quite powerful and robust. We are currently offering two explanatory materials by brush professionals! "How to Properly Choose Bristle Materials for Industrial Brushes (with Chart)" "Solving On-Site 'Problems' with Brushes! Technical Proposal Case Studies" Please take a look at them from the <Catalog Download>. *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company manufactures and sells custom industrial brushes with short lead times, starting from a single unit. Of course, we welcome inquiries about your desired bristle materials and shapes, and after hearing about your challenges, we can also propose brushes suitable for your specific needs. Here, we would like to introduce an example of a grit roll brush. It is made with close winding, resulting in high density. We are currently offering two explanatory materials from brush professionals! "How to Properly Select Bristle Materials for Industrial Brushes (with Chart)" "Solving On-Site 'Problems' with Brushes! Technical Proposal Case Studies" Please take a look at them from the <Catalog Download>. *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company manufactures and sells custom industrial brushes with short lead times, starting from a single unit. Of course, you can consult us about your desired bristle materials and shapes, and after hearing about your challenges, we will also propose brushes suitable for your specific needs. Here, we will introduce examples of brushes made with nylon embedded with grinding stones, known as grit nylon, which are used to grind the workpiece. We are currently offering two explanatory materials from brush professionals! "How to Properly Select Bristle Materials for Industrial Brushes (with Chart)" "Solving On-Site 'Problems' with Brushes! Technical Proposal Case Studies" Please take a look at them from the <Catalog Download>. *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company manufactures and sells custom industrial brushes with short lead times, starting from a single unit. We welcome inquiries about desired bristle materials and shapes, and after listening to your concerns, we can also propose brushes suitable for your specific needs. Here, we would like to introduce a case study of a brush made with brass bristles. Brass is a relatively soft material among metal bristle materials. We are currently offering two explanatory documents by brush professionals! "How to Properly Select Bristle Materials for Industrial Brushes (with Chart)" "Solving On-Site 'Problems' with Brushes! Technical Proposal Case Studies" Please take a look at them from the <Catalog Download>. *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company manufactures and sells custom industrial brushes with short lead times, starting from a single unit. Of course, we welcome consultations regarding your desired bristle materials and shapes, and after hearing about your challenges, we also provide suggestions for brushes suitable for your specific application. Here, we introduce an example of a roll brush with a processed shaft. The brush is attached to a shaft with threaded ends and is made from plated single wire bristles. It is used by inserting it into the interior of a cylinder and is easy to attach to equipment. We are currently offering two explanatory materials from brush professionals! "How to Properly Select Bristle Materials for Industrial Brushes (with Chart)" "Solving On-Site 'Problems' with Brushes! Technical Proposal Case Collection" Please take a look at them from the <Catalog Download>. *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company manufactures and sells custom industrial brushes with short lead times, starting from a single unit. We welcome consultations regarding your desired bristle materials and shapes, and after hearing about your challenges, we also provide suggestions for brushes suitable for your specific application. Here, we will introduce examples of brushes designed for large equipment. We can also handle large R processing. We are currently offering two explanatory documents by brush professionals! "How to Properly Select Bristle Materials for Industrial Brushes (with Chart)" "Solving On-Site 'Problems' with Brushes! Technical Proposal Case Studies" Please take a look at them from the <Catalog Download> section. *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company manufactures and sells custom industrial brushes with short lead times, starting from a single unit. We welcome consultations regarding your desired bristle materials and shapes, and after hearing about your challenges, we also provide suggestions for brushes suitable for your specific application. Here, we will introduce an example of a horsehair brush, which is often used in paper-related machinery. The ring brush is cut in half and welded to a fitting. It is used in machinery related to paper. Animal hair is considered to be less prone to static electricity. We are currently offering two explanatory materials from brush professionals! "How to Properly Choose Bristle Materials for Industrial Brushes (with Chart)" "Solving On-Site 'Problems' with Brushes! Technical Proposal Case Studies" Please check them out from the <Catalog Download>. *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

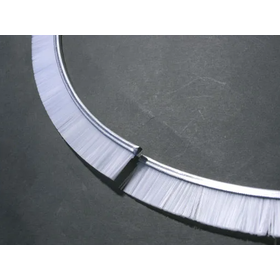

Our company manufactures and sells custom industrial brushes with short lead times, starting from a single unit. Of course, we welcome consultations regarding your desired bristle materials and shapes, and after hearing about your challenges, we also provide suggestions for brushes suitable for your specific needs. Here, we would like to introduce an example of a wire ring brush. The bristles at the joints are minimized. We are currently offering two explanatory materials from brush professionals! "How to Properly Select Bristle Materials for Industrial Brushes (with Chart)" "Solving On-Site 'Problems' with Brushes! Technical Proposal Case Studies" Please take a look at them from the <Catalog Download>. *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

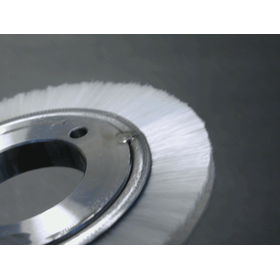

Our company manufactures and sells custom industrial brushes with short lead times, starting from a single unit. Of course, we welcome consultations regarding your desired bristle materials and shapes, and after hearing about your challenges, we also offer suggestions for brushes suitable for your specific needs. Here, we would like to introduce an example of a ring brush. A roll brush that makes a single complete turn is referred to as a ring brush. We are currently offering two explanatory materials from brush professionals! "How to Properly Select Bristle Materials for Industrial Brushes (with Chart)" "Solving On-Site 'Problems' with Brushes! Technical Proposal Case Studies" Please take a look at them from the <Catalog Download>. *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company manufactures and sells custom industrial brushes with short lead times, starting from a single unit. Of course, you can consult us about your desired bristle materials and shapes, and after hearing about your challenges, we will also propose brushes suitable for your specific needs. Here, we will introduce examples of coil brushes made from wire bristles. We are currently offering two explanatory materials from brush professionals! "How to Properly Choose Bristle Materials for Industrial Brushes (with Chart)" "Solving On-Site 'Problems' with Brushes! Technical Proposal Case Studies" Please take a look at them from the <Catalog Download>. *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company manufactures and sells custom industrial brushes with short lead times, starting from a single unit. Of course, we welcome consultations regarding your desired bristle materials and shapes, and after hearing about your challenges, we also provide suggestions for brushes suitable for your specific application. Here, we would like to introduce an example of a coil brush. This brush is in a state without a roll brush shaft and is used for unexpected applications. We are currently offering two explanatory materials from brush professionals! "How to Properly Select Bristle Materials for Industrial Brushes (with Chart)" "Solving On-Site 'Problems' with Brushes! Technical Proposal Case Studies" Please take a look from the <Catalog Download>. *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company manufactures and sells custom industrial brushes with short lead times, starting from a single unit. You can consult us about your desired bristle materials and shapes, and after hearing about your challenges, we will also propose brushes suitable for your specific needs. Here, we introduce an example of a brush made with PPS bristles, which excel in heat and chemical resistance. We are currently offering two explanatory documents by brush professionals! "How to Properly Choose Bristle Materials for Industrial Brushes (with Chart)" "Solving On-Site 'Problems' with Brushes! Technical Proposal Case Studies" Please take a look from the "Catalog Download" section. *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company manufactures and sells custom industrial brushes with short lead times, starting from a single unit. Of course, you can consult us about your desired bristle materials and shapes, and after hearing about your concerns, we will also propose brushes suitable for your specific application. Here, we will introduce examples of brushes that can be attached to routers and drills. We can create a channel brush in a coil shape with a φ8 mounting part that can be attached to equipment or drills. Please consult us regarding the thickness of the mounting shaft. We are currently offering two explanatory materials from brush professionals! "How to Properly Choose Bristle Materials for Industrial Brushes (with Chart)" "Solving On-Site 'Problems' with Brushes! Technical Proposal Case Studies" Please take a look at them from the <Catalog Download>. *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company manufactures and sells custom industrial brushes with short lead times, starting from a single unit. Of course, we welcome inquiries about your desired bristle materials and shapes, and after hearing about your challenges, we also provide suggestions for brushes suitable for your specific application. Here, we would like to introduce an example of a brush using a stepped shaft. By increasing the diameter of the shaft where the bristles are wound, you can increase the amount of bristles. We are currently offering two explanatory materials from brush professionals! "How to Properly Select Bristle Materials for Industrial Brushes (with Chart)" "Solving On-Site 'Problems' with Brushes! Technical Proposal Case Studies" Please take a look at them from the <Catalog Download>. *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company manufactures and sells custom industrial brushes with short delivery times, starting from a single unit. We welcome consultations regarding your desired bristle materials and shapes, and after hearing about your challenges, we can also propose brushes suitable for your specific needs. Here, we will introduce examples of brushes that have been gradually trimmed. Processing like that shown in the photo is also possible. We are currently offering two explanatory materials from brush professionals! "How to Correctly Choose Bristle Materials for Industrial Brushes (with Chart)" "Solving On-Site 'Problems' with Brushes! Technical Proposal Case Studies" Please take a look at them from the <Catalog Download>. *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company manufactures and sells custom industrial brushes with short lead times, starting from a single unit. Of course, we welcome consultations regarding your desired bristle materials and shapes, and after hearing about your challenges, we also provide suggestions for brushes suitable for your specific application. Here, we would like to introduce an example of a roll brush made with Thunderon. Thunderon is a bristle material that has antistatic properties. We are currently offering two explanatory materials from brush professionals! "How to Properly Select Bristle Materials for Industrial Brushes (with Chart)" "Solving On-Site 'Problems' with Brushes! Technical Proposal Case Studies" Please take a look at them from the <Catalog Download>. *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company manufactures and sells custom industrial brushes with short lead times, starting from a single unit. We welcome consultations regarding your desired bristle materials and shapes, and after hearing about your challenges, we can also propose brushes suitable for your specific application. Here, we will introduce an example of a brush wrapped around a shaft that has been processed into a pipe with boss machining and stepped machining. We also accept shaft processing. We are currently offering two explanatory materials from brush professionals! "How to Properly Select Bristle Materials for Industrial Brushes (with Chart)" "Solving On-Site 'Problems' with Brushes! Technical Proposal Case Studies" Please take a look from the <Catalog Download>. *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company manufactures and sells custom industrial brushes with short lead times, starting from a single unit. We welcome consultations regarding your desired bristle materials and shapes, and after hearing about your challenges, we also offer suggestions for brushes suitable for your specific application. Here, we would like to introduce a case where a roll brush was made with goat hair. This soft bristle material is used when you want to avoid scratching the items being cleaned. We are currently offering two explanatory documents by brush professionals! "How to Properly Choose Bristle Materials for Industrial Brushes (with Chart)" "Solving On-Site 'Problems' with Brushes! Technical Proposal Case Collection" Please take a look at them from the <Catalog Download>. *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company manufactures and sells custom industrial brushes with short lead times, starting from a single unit. We welcome consultations regarding your desired bristle materials and shapes, and after hearing about your challenges, we can also propose brushes suitable for your specific needs. Here, we would like to introduce an example of a brush with pitch winding made from Thunderon, which has a static elimination effect. We are currently offering two explanatory materials from brush professionals! "How to Properly Select Bristle Materials for Industrial Brushes (with Chart)" "Solving On-Site 'Problems' with Brushes! Technical Proposal Case Studies" Please take a look at them from the <Catalog Download>. *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company manufactures and sells custom industrial brushes with short lead times, starting from a single unit. Of course, we welcome inquiries regarding the desired bristle materials and shapes, and after hearing about any challenges you may be facing, we also provide suggestions for brushes suitable for your specific needs. Here, we would like to introduce an example of a roll brush made with nylon [grit] bristles. This type of brush is sometimes referred to as a "dragonfly brush." We are currently offering two explanatory materials from brush professionals! "How to Properly Select Bristle Materials for Industrial Brushes (with Chart)" "Solving On-Site 'Problems' with Brushes! Technical Proposal Case Studies" Please take a look at them from the <Catalog Download> section. *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company manufactures and sells custom industrial brushes with short lead times, starting from a single unit. You can consult us about your desired bristle material and shape, and after hearing about your challenges, we will also propose brushes suitable for your specific needs. Here, we introduce an example of a brush with palm bristles, which are commonly used for scrubbing pads and similar applications. We are currently offering two explanatory materials from brush professionals! "How to Properly Select Bristle Materials for Industrial Brushes (with Chart)" "Solving On-Site 'Problems' with Brushes! Technical Proposal Case Studies" Please take a look at them from the "Catalog Download" section. *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company manufactures and sells custom industrial brushes with short lead times, starting from a single unit. We welcome consultations regarding your desired bristle materials and shapes, and after hearing about your challenges, we also propose brushes suitable for your specific needs. Here, we introduce an example of a horsehair roll brush. It is often used in places where paper, such as for printing, is involved. The bristles are soft to the touch. We are currently offering two explanatory materials from brush professionals! "How to Properly Select Bristle Materials for Industrial Brushes (with Chart)" "Solving On-Site 'Problems' with Brushes! Technical Proposal Case Studies" Please take a look at them from the <Catalog Download>. *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company manufactures and sells custom industrial brushes with short lead times, starting from a single unit. We welcome consultations regarding your desired bristle materials and shapes, and after hearing about your challenges, we can also propose brushes suitable for your specific needs. Here, we would like to introduce an example of a small roll brush that is stronger than a twisted brush. This is a small brush with an outer diameter of φ30. By using channel 2, we can produce even smaller brushes. Please inquire about the sizes available for production. If you require more strength than a twisted brush, we recommend a channel brush. We are currently offering two explanatory materials from brush professionals! "How to Properly Choose Bristle Materials for Industrial Brushes (with Chart)" "Solving On-Site 'Problems' with Brushes! Technical Proposal Case Studies" Please take a look at them from the <Catalog Download>. *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company manufactures and sells custom industrial brushes with short lead times, starting from a single unit. You can consult us about your desired bristle material and shape, and after hearing about your challenges, we will also propose brushes suitable for your specific application. Here, we will introduce an example of a roll brush that is wound in a coil shape and then attached to a shaft. As shown in the photo above, it can be processed into a coil shape before being mounted on the shaft. Green nylon is used to make it easier to identify when bristles are mixed in. We are currently offering two explanatory materials by brush professionals! "How to Properly Select Bristle Materials for Industrial Brushes (with Chart)" "Solving On-Site 'Problems' with Brushes! Technical Proposal Case Studies" Please take a look at them from the <Catalog Download>. *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company manufactures and sells custom industrial brushes with short lead times, starting from a single unit. Of course, we welcome consultations regarding your desired bristle materials and shapes, and after hearing about your challenges, we also offer suggestions for brushes suitable for your specific needs. Here, we introduce an example of a green brush that is easy to spot even when bristles break. We use green to make it easier to identify when bristles from the brush mix into food in a factory. This is based on the same concept as the green rubber bands used in prepared food sections. We are currently offering two explanatory materials by brush professionals! "How to Properly Choose Bristle Materials for Industrial Brushes (with Chart)" "Solving On-Site 'Problems' with Brushes! Technical Proposal Case Studies" Please take a look at them from the "Catalog Download" section. *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company manufactures and sells custom industrial brushes with short lead times, starting from a single unit. You can consult with us about your desired bristle materials and shapes, and after hearing about your challenges, we will also propose brushes suitable for your specific needs. Here, we would like to introduce an example of a spiral cone brush. It is a roll brush with a dome-shaped tip. Green nylon is used. Please note that we cannot replace the bristles embedded at the tip of the brush, as they are secured by crimping the pipe. We are currently offering two explanatory materials from brush professionals! "How to Properly Choose Bristle Materials for Industrial Brushes (with Chart)" "Solving On-Site 'Problems' with Brushes! Technical Proposal Case Collection" Please check them out from the <Catalog Download>. *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company manufactures and sells custom industrial brushes with short lead times and from a minimum order of one piece. We welcome inquiries regarding your desired bristle materials and shapes, and after hearing about your challenges, we can also suggest brushes suitable for your specific needs. Here, we would like to introduce an example of a small-sized cup brush. It is rare to make a cup brush in green, but it is certainly possible to produce. Please inquire about the dimensions that can be manufactured. We are currently offering two explanatory materials from brush professionals! "How to Properly Choose Bristle Materials for Industrial Brushes (with Chart)" "Solving On-Site 'Problems' with Brushes! Technical Proposal Case Studies" Please check them out via the "Catalog Download." *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company manufactures and sells custom industrial brushes with short lead times, starting from a single unit. Of course, we welcome consultations regarding your desired bristle materials and shapes, and after hearing about your challenges, we can also propose brushes suitable for your specific needs. Here, we would like to introduce an example of a brush with an R shape. This is quite a specialized brush. The dimensions of the R part require a larger R as the channel size increases. We are currently offering two explanatory documents from brush professionals! "How to Properly Select Bristle Materials for Industrial Brushes (with Chart)" "Solving On-Site 'Problems' with Brushes! Technical Proposal Case Studies" Please take a look at them from the <Catalog Download>. *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company manufactures and sells custom industrial brushes with short lead times, starting from a single unit. Of course, we welcome consultations regarding your desired bristle materials and shapes, and after hearing about your challenges, we also offer suggestions for brushes suitable for your specific needs. Here, we introduce an example of a two-row seal brush. We enhanced the sealing and blocking purpose by arranging straight brushes in two rows. We are currently offering two explanatory materials from brush professionals! "How to Properly Select Bristle Materials for Industrial Brushes (with Chart)" "Solving On-Site 'Problems' with Brushes! Technical Proposal Case Studies" Please take a look from the <Catalog Download>. *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company manufactures and sells custom industrial brushes with short lead times, starting from a single unit. We welcome consultations regarding your desired bristle materials and shapes, and after hearing about your challenges, we can also propose brushes suitable for your specific needs. Here, we would like to introduce an example of a linear brush designed to prevent bristle contamination. Green bristle materials are commonly used in food factories. This is a linear brush for sealing gaps. We are currently offering two explanatory materials from brush professionals! "How to Properly Select Bristle Materials for Industrial Brushes (with Chart)" "Solving On-Site 'Problems' with Brushes! Technical Proposal Case Collection" Please take a look at them from the <Catalog Download>. *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company manufactures and sells custom industrial brushes with short lead times, starting from a single unit. We welcome consultations regarding your desired bristle materials and shapes, and after hearing about your challenges, we can also suggest brushes suitable for your specific needs. Here, we would like to introduce an example of a roll brush using pakin. Among plant-based bristle materials, pakin is the most commonly used in industrial applications. We are currently offering two explanatory documents by brush professionals! "How to Properly Choose Bristle Materials for Industrial Brushes (with Chart)" "Solving On-Site 'Problems' with Brushes! Technical Proposal Case Studies" Please take a look at them from the <Catalog Download> section. *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company manufactures and sells custom industrial brushes with short lead times, starting from a single unit. We welcome consultations regarding your desired bristle materials and shapes, and after hearing about your challenges, we can also propose brushes suitable for your specific application. Here, we would like to introduce an example of a small roll brush. It may be hard to tell from the photo, but it is actually quite compact. Just as there are various sizes of equipment, we are also skilled at producing brushes tailored to those sizes. If the shafts or pipes are smaller, the channels for winding will also be smaller. We are currently offering two explanatory materials from brush professionals! "How to Properly Select Bristle Materials for Industrial Brushes (with Chart)" "Solving On-Site 'Problems' with Brushes! Technical Proposal Case Studies" Please take a look at them from the <Catalog Download>. *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We manufacture and sell custom industrial brushes with short lead times, starting from a single unit. Of course, you can consult us about your desired bristle material and shape, and after hearing about your concerns, we will also propose brushes suitable for your specific application. Here, we would like to introduce an example of a pitch-wound roll brush. The size of the channel for winding changes depending on the thickness of the shaft or pipe. Please feel free to consult us. We are currently offering two explanatory materials by brush professionals! "How to Properly Select Bristle Materials for Industrial Brushes (with Chart)" "Solving On-Site 'Problems' with Brushes! Technical Proposal Case Studies" Please take a look at them from the "Catalog Download" section. *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company manufactures and sells custom industrial brushes with short lead times, starting from a single unit. Of course, we welcome consultations regarding your desired bristle materials and shapes, and after hearing about your challenges, we also provide suggestions for brushes suitable for your specific application. Here, we introduce an example of a pitch-wound brush that drops debris to the left and right. By changing the winding direction, we alter the sweeping direction of dust and debris. In the case of the brush shown in the photo, it sweeps debris outward. We are currently offering two explanatory materials from brush professionals! "How to Properly Select Bristle Materials for Industrial Brushes (with Chart)" "Solving On-Site 'Problems' with Brushes! Technical Proposal Case Studies" Please take a look from the <Catalog Download>. *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company manufactures and sells custom industrial brushes with short lead times, starting from a single unit. We welcome consultations regarding your desired bristle materials and shapes, and after hearing about your challenges, we can also propose brushes suitable for your specific needs. Here, we introduce an example of a roller brush for conveyors. The finer the bristle diameter, the higher the density of the bristle tips, while the thicker the bristle, the coarser the density of the tips. We are currently offering two explanatory materials from brush professionals! "How to Properly Select Bristle Materials for Industrial Brushes (with Chart)" "Solving On-Site 'Problems' with Brushes! Technical Proposal Case Studies" Please take a look from the <Catalog Download>. *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company manufactures and sells custom industrial brushes with short lead times, starting from a single unit. We welcome consultations regarding your desired bristle materials and shapes, and after hearing about your challenges, we can also propose brushes suitable for your specific application. Here, we introduce an example of a roll brush used for cleaning conveyors. The minimum shaft diameter that can be wrapped around the axis is determined by the channel size. For #3, it is φ6 or more, for #5, it is φ10 or more for plated steel, and φ12 or more for SUS430. Due to various processing limits, there may be cases where the bearing part is processed to a smaller size in steps. We are currently offering two explanatory materials from brush professionals! "How to Properly Select Bristle Materials for Industrial Brushes (with Chart)" "Solving On-Site 'Problems' with Brushes! Technical Proposal Case Collection" Please take a look from the <Catalog Download>. *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration