1~14 item / All 14 items

Displayed results

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Contact this company

Inquiry FormBefore making an inquiry

Download Profile1~14 item / All 14 items

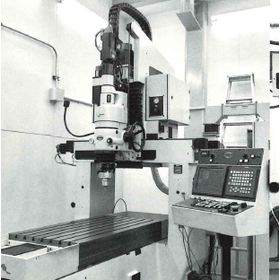

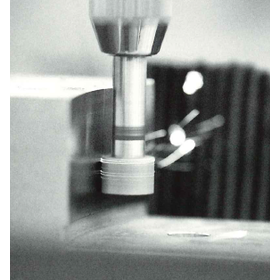

Our company has been engaged in jig grinding for many years and, as professionals in jig grinding, we provide proposals that meet our customers' needs. The CNC gantry jig grinding machine can perform jig grinding processing for large products exceeding 1 meter. It can also meet the stringent quality requirements for dimensional accuracy and durability demanded by precision molds made of cemented carbide. Additionally, we can handle a variety of processing tasks, including post holes, bushing holes, knock pin holes for press molds, and corner pockets for insert molds. 【Features】 ■ High precision of 1/1,000mm ■ BCP established at two locations: Yokohama and Niigata ■ Versatile processing and diverse materials ■ From part processing to final finishing ■ Maximum work size of 1,200mm ■ Capable of general part processing and mold production *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Ishii Seiki Co., Ltd. provides full support for jig grinding, including jig grinding processing and the import and sale of overseas jig grinding machines. We offer proposals for retrofitting existing grinding machines to NC-equipped jig grinding machines, and we also dispatch staff to customers' factories to carry out repairs on jig grinding machines. Additionally, we provide technical guidance on jig grinding processing, so if you encounter any issues with grinding, we will share our processing technology know-how. 【Services Offered】 ■ Jig grinding processing ■ Import and sale of overseas jig grinding machines ■ Retrofit of jig grinding machines ■ On-site repairs of jig grinding machines ■ Repair of grinding head motors (motor balance adjustment, loan of replacement machines) ■ Technical guidance on jig grinding processing *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company operates a two-base system in Yokohama and Niigata, providing high-precision jig grinding processing and maintenance services for Moore jig grinding machines. We offer contract jig grinding services, import and sales of overseas jig grinding machines, retrofitting of jig grinding machines, on-site repairs and maintenance for Moore jig grinding machines, repairs and overhauls of grinding head motors, and technical guidance for jig grinding processing. We own 12 CNC gantry jig grinding machines and CNC jig grinding machines. You can rely on us for short delivery times, small quantities, large items, and items with irregular shapes. 【Overview】 ■ Main Products - Jig grinding processing, production of food and medical-related dies, precision parts processing ■ Equipment - Yokohama Headquarters Factory: 10 jig grinding machines, 1 three-dimensional measuring machine, and other measuring tools - Niigata Factory: 6 jig grinding machines, 1 three-dimensional measuring machine, and other measuring tools *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company offers "High-Precision Jig Grinding/Moore Jig Grinder Maintenance Services." We provide a variety of services including contract jig grinding, import and sales of overseas jig grinders, retrofitting of jig grinders, and technical guidance for jig grinding. Through jig grinding, we deliver "products that require precision" such as mold components, precision parts, optics, automotive-related items, chemical products, medical devices, and food-related items to the market. We accept requests from all over Japan. Please feel free to contact us. 【Features】 ■ Grinding by specialized technicians focusing on Moore G18/G48 ■ High-precision processing of 1/1,000mm ■ Capable of diverse processing and various materials ■ Support from material procurement to rough processing and finishing ■ Quick response with two factory locations and two gantry machines *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company possesses machining technology at the micron level (1/1,000 mm) and responds quickly to requests for "high-precision jig grinding" from the start of production at our two bases in Yokohama and Niigata. We offer a wide range of jig grinding techniques, including post holes, bush holes, and knock pin holes for press molds, as well as corner pockets for insert molds. We can accommodate diverse machining needs and various materials, handling everything from material procurement to rough machining and finishing processes. We accept requests from all over Japan. Please feel free to contact us for any inquiries. 【Features】 ■ Ultra-precision grinding with high accuracy of 1/1,000 mm ■ Precision hole machining and precision processing of hard materials through jig grinding ■ High-precision machining of large items at 1/1,000 mm ■ Quick response with two factory locations and two gantry machines *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company specializes in contract jig grinding, importing and selling overseas jig grinding machines, and retrofitting jig grinding machines. Additionally, we provide on-site repair and maintenance for Moore jig grinding machines, repair and overhaul of grinding head motors, and technical guidance for jig grinding processes. We can handle a wide variety of machining and diverse materials, from material procurement to rough machining and finishing processes. We accept requests from all over Japan, so please feel free to contact us for any inquiries. 【Features】 ■ Two locations in Yokohama and Niigata ■ Jig grinding with precision of 0.001mm ■ High precision and high quality ■ Nationwide service *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Ishii Seiki Co., Ltd. is a company that specializes in jig grinding, parts processing, and ultra-high precision mold manufacturing. The maximum processing range is 600mm × 1200mm × 500mm, and we can accommodate even longer items through joint processing. Additionally, we can process large products exceeding 1 meter using CNC gantry jig grinding machines. Furthermore, we operate with a two-location system, so there is no waiting time from order to production start. 【Features】 ■ Grinding by specialized technicians centered around Moore G18/G48 ■ High precision processing of 1/1,000mm ■ Capable of diverse processing and various materials ■ Able to handle everything from material procurement to rough and finishing processes ■ Two-location system in Yokohama and Niigata *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

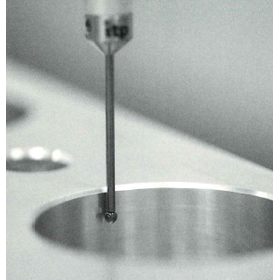

Our company provides high-precision jig grinding and maintenance services for Moore jig grinding machines. We are well-suited for precision hole machining and precision grinding of hard materials, such as motor cores related to the automotive industry, which have stringent quality requirements for dimensional accuracy and durability in recent years. Additionally, with two factory locations and a two-machine gantry system, we can respond quickly, ensuring there is no waiting time from order to production start. 【Features】 ■ Jig grinding with an accuracy of 0.001mm ■ High precision and high quality ■ Nationwide service *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company specializes in jig grinding, transforming what our customers need into tangible results in manufacturing. We offer a wide range of grinding techniques for jigs, including post holes, bush holes, and knock pin holes for press molds, as well as corner pockets for insert molds. Additionally, we undertake parts processing with consistent production in collaboration with partner companies, and we manufacture molds for cutting packaging containers and battery separator cutting molds using ultra-high precision mold technology that achieves 1/1,000mm accuracy. 【Features】 ■ Two bases in Yokohama and Niigata ■ Grinding by specialized technicians centered on Moore G18/G48 ■ High-precision processing of 1/1,000mm ■ Capable of diverse processing and various materials ■ Support from material procurement to rough processing and finishing processes *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Since our establishment, we have been engaged in manufacturing for many years and are a company specializing in ultra-high precision jig grinding. We are capable of processing large products over 1 meter using CNC gantry jig grinding machines. Furthermore, with our two-location system, there is no delay from order to production start. Additionally, we possess machining technology at the micron level (1/1,000 mm), and we hope you can utilize us as your precision machining partner to enhance quality and profitability. 【Features】 ■ Ultra-precision grinding with high accuracy of 1/1,000 mm ■ Precision hole machining and precision processing of hard materials through jig grinding ■ High-precision processing of large items at 1/1,000 mm ■ Quick response with two factory locations and two gantry machines *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company possesses machining technology at the micron level (1/1,000 mm) and responds quickly to requests for "high-precision jig grinding" from the start of production at our two bases in Yokohama and Niigata. We are well-suited for precision hole machining and precision grinding of hard materials, such as motor cores related to the automotive industry, where recent demands for dimensional accuracy and durability are stringent. We accept various processing services, including jig grinding, parts machining in a consistent production process, and the manufacturing of ultra-high-precision molds. Please feel free to contact us for any inquiries. 【Features】 ■ Grinding by specialized technicians centered on Moore G18/G48 ■ High-precision machining at 1/1,000 mm ■ Capable of diverse processing and various materials ■ Able to handle everything from material procurement to rough and finishing processes *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company owns a total of 19 jig grinding machines manufactured by Moore, renowned for their world-class precision (such as G18/G48), and we offer "ultra-high precision jig grinding" with an accuracy of 1/1000mm (micron order). We can provide a comprehensive response from material procurement to rough processing and final finishing, making us ideal for the production of mold components and precision jigs that require micron-level clearance. With our two bases in Yokohama and Niigata, we can respond quickly to requests from all over the country. In addition to providing processing technology, we also offer "machine maintenance services" as specialists in Moore jig grinding machines. We handle a wide range of services including the import and sale of overseas jig grinding machines, on-site repairs, maintenance, retrofitting, overhaul of grinding head motors, and even technical guidance. Whether you are "looking for a processing provider" or "experiencing issues with your jig grinding machine," we will solve all challenges related to jig grinding with our reliable technology and equipment capabilities.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is an introduction to Ishii Seiki's "Jig Polishing Processing," featuring operators well-versed in "grinding" and high-performance equipment. 【Features】 - Reliable quality control system… Assurance through improved work quality, optimal temperature settings, and measurement data. - Production system from order to delivery… Thorough visible management, establishment of recovery systems, and preparation for next-generation production management. *For other functions and details, please download the catalog or contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Make your wishes come true! Introducing the "Multi Star Gauge mmg Type I," which combines various cages into one. 【Features】 - Equipped with 6 ring cages (customizable) - Squareness function - Reusable through regrinding - Space-saving and low cost *For other features and details, please download the catalog or contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration