1~45 item / All 45 items

Displayed results

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Contact this company

Contact Us Online1~45 item / All 45 items

Kyoei Electric Co., Ltd. is planning to release a user-direct sales limited model rotary connector, the 'RCK420'. This product is a 4-pole type that does not use the hazardous substance mercury and can also be used for heater and thermocouple specifications. Additionally, we have renewed our website. The structure and design have been completely revamped to make it easier for users to find information. It has also been optimized for viewing on smartphones and tablet devices. For more details, please feel free to contact us. https://www.kyoeidenki.jp/ 【Features】 ■ Mercury-free ■ Compliant with RoHS2 directive ■ Maintenance-free ■ Allowable rotation speed of 1500 rpm *For more details, please refer to the related links or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "SRE040-100A-C" is a newly developed earth slip ring that does not use the hazardous substance mercury. It can be used in high-temperature environments up to 80°C, which was not possible with mercury types. Thanks to its unique structure in the contact area, it achieves long life and maintenance-free operation, making it suitable for rotating equipment that requires grounding, such as plating devices (hoop plating, barrel plating) and welding machines. 【Features】 ■ Does not use the hazardous substance mercury ■ Installation direction can be freely set ■ Compliant with RoHS directive ■ Rotational life of 30 million revolutions ■ Maintenance-free *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Good news for customers looking for high-performance and low-cost slip rings. Custom-made products and high-performance items that require considerable manufacturing effort are very expensive from other companies, and customers have faced the challenge of not being able to allocate a budget for them. By leveraging our strengths in in-house production, we can offer high-performance products at lower prices than our competitors. [Case Overview] ■ Equipment - Film manufacturing equipment, filling machines, etc. ■ Challenge - Need for custom-made products and high-performance items that require considerable manufacturing effort ■ Solution - Ability to provide high-performance products at lower prices than competitors *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is a one-pole type rotary connector that does not use mercury, a harmful substance. By implementing liquid gallium alloy with high reliability, we have achieved maintenance-free operation for 100 million rotations. It can be used for rotating equipment that requires grounding, such as plating machines and welding machines. <Features> ■ Mercury-free, compliant with RoHS 2 ■ Low contact resistance (below 1mΩ) ■ Low torque (below 0.45cN·m) ■ Long lifespan ■ Capable of handling high currents ■ Maintenance-free ■ Capable of high-speed rotation ■ Compact design ■ Can be disposed of as regular industrial waste *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company contributes to an efficient development schedule with prompt responses. Due to the nature of machine manufacturing, a slip ring was needed within a month and a half, but we faced a challenge as existing manufacturers stated it would take three months. Our company can respond with short delivery times by leveraging our strengths in domestic production. We delivered a product with equivalent performance within a month and a half, contributing to the development schedule. [Case Overview] ■ Equipment - Packaging machinery, heating heaters, etc. ■ Challenge - A slip ring was needed within a month and a half ■ Solution - Delivered a product with equivalent performance within a month and a half, contributing to the development schedule *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We accept custom orders for the production of equivalent products in small quantities. There was a challenge in purchasing carbon brushes for a motor because they were an old type and could not be bought. In response, we manufactured equivalent products. Since only the carbon brushes needed to be replaced, our customers were pleased. [Case Overview] ■ Equipment - Motors, etc. ■ Challenge - Wanting to purchase old-type carbon brushes ■ Solution - Manufactured equivalent products - Only the carbon brushes needed to be replaced *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company provides stable communication with reliable technology. There was a problem with frequent communication errors when using slip rings from other manufacturers (power + communication). By replacing them with Kyoei Electric's products, the errors were resolved. We have reliable technology that prevents interference between power and communication. 【Case Overview】 ■ Equipment - 2-axis winding machine, battery manufacturing line, etc. ■ Issue - Frequent communication errors ■ Solution - Errors were resolved by replacing with our products - Reliable technology that prevents interference between power and communication *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce a case study on solving issues in the food machinery industry. With slip rings from other manufacturers, we were struggling to accurately read the signals from thermocouples. At Kyoei Electric, we have the unique know-how developed over many years, which allows us to achieve high-precision signal transmission from thermocouples, and we have numerous successful cases. [Case Overview] ■ Equipment - Food manufacturing machines, semiconductor manufacturing equipment, etc. ■ Challenge - Need for stable thermocouple signals ■ Solution - High-precision signal transmission from thermocouples made possible by our unique know-how developed over many years - Numerous successful cases *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company provides reliable quality through thorough quality control in domestic production. By replacing mercury-containing products with mercury-free products manufactured by Kyoei Electric, we contribute to environmental considerations and cost reduction! 【Case Overview】 ■ Equipment - Hoop plating equipment, etc. ■ Challenges - We want to use mercury-free products, but other companies' mercury-free products have high failure rates, and the costs associated with switching are a concern. ■ Solution - By utilizing the know-how of a slip ring specialist manufacturer and implementing a unique structure, we achieved performance equivalent to mercury products. Furthermore, by offering low prices through direct sales, we were able to facilitate the replacement of mercury products. *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce a case study on solving issues in the industrial machinery industry. There was a challenge of not having a manufacturer capable of repairing slip rings for winding motors and generators. Our company can provide flexible responses thanks to our skilled technicians. We also have a track record of handling difficult repair cases. 【Case Overview】 ■ Equipment - Motors for cranes, etc. ■ Challenge - Struggling to find a repair service for slip rings ■ Solution - Flexible responses made possible by skilled technicians *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce our application-specific problem-solving case study on "Semiconductor Manufacturing Equipment." In addition to accommodating high voltages in the thousands of volts range, there were also size limitations due to equipment space constraints, which posed the issue that accommodating high voltage typically requires larger equipment. To address this, we adopted a unique structure for the metal contacts that minimizes resistance, and replaced almost all components used in the slip ring with materials that have significantly higher insulation properties than usual. Furthermore, by customizing the processing of components and the internal structure to special specifications, we were able to keep the size to a minimum. 【Case Overview】 ■ Challenges - Accommodating high voltage typically requires larger equipment. ■ Results - Achieved both high voltage accommodation in the thousands of volts range and compactness. *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce a case study of solving problems in the industrial machinery industry. We were looking for a slip ring manufacturer that could handle servo motors, but we were turned down by all and found ourselves at a dead end. Kyoei Electric has the know-how to balance power and communication, and has a proven track record in applications for servo motors. 【Case Summary】 ■ Equipment - Industrial sewing machines, 2-axis winding machines, etc. ■ Challenge - Need for a slip ring compatible with servo motors ■ Solution - Proven track record in applications for servo motors *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce our application-specific problem-solving case study: "Roll Heater (Food Manufacturing Equipment)." The thermocouple signals from the roll heater were being read through a slip ring from another company, but there was a challenge due to low accuracy, which prevented the correct signals from being read. In response, we provided a slip ring that employs metal brushes, which have low resistance at the sliding contacts and can stably read signals. As a result, it became possible to read the thermocouple signals stably. 【Case Summary】 ■Challenge - The slip ring had low accuracy and could not read the correct signals. ■Result - It became possible to read the thermocouple signals stably. *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce our application-specific problem-solving case study: "Hoop Plating Processing Equipment." We faced the challenge of having used rotary connector products containing mercury, but due to environmental measures, we could no longer use products that contained mercury. In response, we proposed the mercury-free single-pole rotary connector GRC-1-250. Not only did we satisfy environmental concerns, but we also met performance and cost expectations, allowing for a replacement of the mercury-containing products. 【Case Overview】 ■Challenge - Due to environmental measures, products containing mercury could no longer be used. ■Result - By utilizing the expertise of a slip ring specialist manufacturer and employing a unique structure different from other companies, we were able to achieve performance equivalent to that of mercury products. Additionally, by offering a direct sales-only specification to users, we were able to keep product costs down, providing cost benefits as well. *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce our application-specific problem-solving case study: "Industrial Sewing Machines." We were looking for a slip ring that could transmit to a servo motor, but we were turned down by other domestic manufacturers who claimed that it was impossible to transmit the servo power and the noise-sensitive encoder signal correctly at the same time. In response, we adopted a metal brush with minimal resistance change and strong noise immunity for the sliding contacts. We used a shielded cable specifically designed for servo applications, developing a slip ring that prevents power noise from interfering with the encoder signal. As a result, we successfully transmitted the servo motor's power and encoder signal correctly at the same time. Subsequently, this servo motor-compatible slip ring was officially adopted and has been continuously installed in many industrial sewing machines. [Case Summary] ■ Challenges - Unable to transmit the servo power and noise-sensitive encoder signal correctly at the same time. ■ Results - Successfully transmitted the servo motor's power and encoder signal correctly at the same time. *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Essential for powering rotating bodies: that is the slip ring system (collecting device). In recent years, the advancement of various industrial machines has been truly remarkable, following a path of increasing complexity and sophistication. The slip ring system plays a crucial role in alleviating these complex functions. Based on years of experience and technology, our company continues to make unceasing progress to establish greater trust in response to the needs of our users. <Case Studies for Problem Solving> - Unable to use mercury due to environmental considerations - Want to stabilize the reading of thermocouple signals - High voltage, but want to minimize the size of the housing as much as possible - Want to use a servo motor through a slip ring, etc.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "GRC-1-250" is a one-pole type rotary connector that uses liquid gallium alloy instead of mercury and is suitable for high-temperature environments (up to 80°C). It can be installed in both vertical and horizontal orientations, making it a viable replacement for existing rotary connectors. With low torque, low noise, and stable resistance values, it is effective for various applications. It complies with the RoHS2 directive and can be disposed of as regular industrial waste, contributing to reduced disposal costs. 【Features】 ■ Made in Japan ■ Compliant with RoHS2 directive ■ Low torque ■ High current ■ Low noise and low contact resistance (below 1mΩ) due to no contact points used ■ Usable in high-temperature environments compared to mercury (4-80°C) ■ Can be processed as regular industrial waste *We are currently providing materials that include test data on electrical characteristics. You can view them via PDF download. Please feel free to contact us for inquiries.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The slip ring systems (collecting devices) that our company handles are essential mechanical components for supplying power to rotating bodies. In recent years, the advancements in various industrial machines have been truly remarkable, following a path of increasing complexity and sophistication. The slip ring system plays an important role in alleviating these complex functions. Based on many years of experience and technology, our company continues to make unceasing progress to establish greater trust in response to the needs of our users. Currently, we are offering a collection of case studies addressing various challenges related to slip rings! Please feel free to view them from the "PDF Download."

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company contributes to an efficient development schedule with prompt responses. Due to the nature of machine manufacturing, a slip ring is needed within a month and a half, but we faced a challenge as an existing manufacturer stated it would take three months. Our company can respond with short delivery times by leveraging the strengths of our domestic production. We delivered products with equivalent performance in a month and a half, contributing to the development schedule. [Delivery Examples] 1. Communication + Power + Special Shape Slip Rings Delivery Example: Filling machines, etc. 2. Flange + Terminal Block Type Multi-pole Slip Rings Delivery Example: 2-axis turret winders, etc. 3. Split Slip Rings Delivery Example: Agitators, etc. *For more details, please download the materials or contact us directly.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company contributes to an efficient development schedule with "high performance, short delivery times, and low prices," leveraging the strengths of our domestic production. "If there are no manufacturers that can handle complex specifications" or "existing products require long delivery times and are expensive," please feel free to consult with us if you have similar concerns! 【Our Features】 ■ High Performance: We have numerous improved defect cases! We leverage the strengths of a specialized slip ring manufacturer! ■ Short Delivery Times: We contribute to your desired delivery times with flexible designs based on in-house integrated production and standard products! ■ Low Prices: We can further reduce prices through a direct sales system! *For more details, please download the materials or contact us directly.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is a compact slip ring with an outer diameter of φ30 that supports 3A power and various communication standards. By adopting a unique wire contact design, it offers high noise resistance and allows for simultaneous power and communication supply. Additionally, it achieves an industry-leading lifespan of 100 million rotations maintenance-free, contributing to reduced running costs. It can be used in many rotating devices that require control of power and communication. We kindly ask you to consider it. 【Features】 ■ Long lifespan of 100 million rotations ■ Maintenance-free ■ High-speed rotation of 1200rpm ■ Simultaneous power and communication supply possible ■ Short delivery time ■ Cost reduction *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The small high-speed communication slip ring "SAZA/SCZA series" is a compact slip ring with an outer diameter of φ30 that supports 3A power and various communication standards. By adopting a unique wire contact design, it offers high noise resistance and allows simultaneous power and communication supply. Additionally, it achieves an industry-leading lifespan of 100 million rotations maintenance-free, contributing to reduced running costs. It can be used in many rotating devices that require power and communication control. We kindly ask you to consider it. 【Features】 ■ Stable signal transmission at high rotation speeds of 1200rpm ■ Simultaneous power and communication supply is possible ■ Short delivery times are available! ■ Achieves an affordable price while maintaining industry-leading lifespan *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company leverages the strengths of our integrated domestic system to contribute to an efficient development schedule with "high performance, short delivery times, and low prices." If you are facing any similar concerns such as "there are no manufacturers that can meet our specifications" or "existing products require long lead times and are expensive," please feel free to consult with us! 【Our Features】 ■ High Performance: We have numerous improved defect cases! We utilize the strengths of a specialized slip ring manufacturer! ■ Short Delivery Times: Our integrated in-house production and flexible design based on standard products contribute to your desired delivery times! ■ Low Prices: We can further reduce prices through a direct sales system! *For more details, please download our materials or contact us directly.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

- High performance that surpasses mercury products - Compact, high current, high-speed rotation - Ideal for industrial machinery such as packaging machines

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Essential for the power supply of rotating bodies is the slip ring system (collecting device). In recent years, the advancements in various industrial machines have been truly remarkable, following a path of increasing complexity and sophistication. The slip ring system plays a crucial role in alleviating this complex functionality. Based on many years of experience and technology, our company continues to make unceasing progress to meet the needs of our users and further establish trust.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "SRC7A Series" is a multi-pole slip ring system developed specifically for signal circuits, featuring a monolithic structure. The voltage specifications are AC200V and DC100V, with the number of poles set from 1 to 40 as a quasi-standard specification. It uses special alloy brushes suitable for detecting small currents. The use of aluminum for the boss and bracket contributes to weight reduction. 【Features】 ■ Monolithic structure ■ Developed for signal circuits ■ Number of poles set from 1 to 40 as a quasi-standard specification ■ Uses special alloy brushes suitable for detecting small currents ■ Weight reduction achieved by using aluminum for the boss and bracket *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "SRC30" is a compact slip ring system with an outer diameter of φ30. It can be used for a wide range of applications, including currents below 1A, microcurrents, and signals. Additionally, it has a pole number of 4, 8, 12, 16, or 20P, a voltage rating of 100V or less, a rotational speed of 400rpm or less, and a rotational lifespan of 60 million rotations. 【Features】 ■ Compact type with an outer diameter of φ30 ■ Usable for a wide range of applications, including currents below 1A, microcurrents, and signals *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "SRC110" is a compact, high-capacity, hollow mount type product. It can be used for various applications from power to signal. Its outstanding longevity also contributes to cost reduction. It can be easily replaced with products from other manufacturers. 【Features】 ■ Compact, high-capacity, hollow mount type ■ Usable for various applications from power to signal ■ Outstanding longevity contributes to cost reduction ■ Can be replaced with products from other manufacturers *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "SRY36A series" is a multipole slip ring system with a permissible current of 36A. The insulation resistance is over 50MΩ (500V), and the number of poles is set from 1 to 18 as a semi-standard specification. 【Standard Specifications】 ■ Voltage: AC200V DC100V ■ Permissible Current: 36A ■ Insulation Resistance: Over 50MΩ (500V) ■ Insulation Withstand Voltage: 2500V 1min ■ Number of Poles: 1 to 18 ■ Rotation Direction: cw-ccw ■ Permissible Rotational Speed: 2000rpm *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "SRY80A Series" is a multipole slip ring system with a permissible current of 80A. The number of poles is set from 1 to 21 as a quasi-standard specification. The insulation resistance is 2500V for 1 minute, and the permissible rotation speed is 2000rpm. 【Standard Specifications】 ■ Voltage: AC200V DC100V ■ Permissible Current: 80A ■ Insulation Resistance: 50MΩ (500V) or more ■ Insulation Strength: 2500V for 1 minute ■ Number of Poles: 1 to 21 ■ Rotation Direction: cw-ccw ■ Permissible Rotation Speed: 2000rpm *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

At Kyoei Electric Co., Ltd., we offer "custom-made brushes" using standard processing methods for electric brushes. Materials include copper-based, silver-based, and graphite-based, with various processing methods available such as "no connecting cord" and "split diamond shape." We can manufacture a variety of carbon brushes from samples or drawings. [Contents] ■ No connecting cord ■ Copper powder stop, solder stop ■ Cap stop ■ Copper tube (1 piece) crimping ■ Copper tube (2 pieces) crimping ■ Split diamond shape *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "CB Series" consists of brushes for sliding contacts used in slip rings. FM material is a copper-based brush suitable for power and heater applications, while KA material is a silver-based brush suitable for signal applications and the detection of small currents such as thermocouples. We offer compatible holders such as "C4-1" for BH2012, BH3216, BH4020, and "C1-4" for V-50 and V-60. 【Features】 ■ Sliding contacts used in slip rings ■ FM material is a copper-based brush ideal for power and heater applications ■ KA material is a silver-based brush ideal for signal applications and the detection of small currents such as thermocouples *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "B Series" is a brush holder with a double brush design. Due to the large brush dimensions, it is suitable for high-capacity current supply. The material is BS, and we offer three types of current: 80A, 160A, and 240A. 【Features】 ■ Double brush design ■ Suitable for high-capacity current supply due to large brush dimensions ■ Material is BS *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "M Series / Brush Cap" is a product made from molded parts, designed to be offered at a low price. The "M Series" is available in four sizes: 6.5×6, 7×6, and others. There are six types of "Brush Caps," with materials available in phenol and BS type. Please use them according to your application. 【M Series Lineup】 ■BHB-665 ■BHB-67 ■BHB-638 ■BHB-711 *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "S Series" is a brush holder designed with a compact structure that can be used regardless of the outer diameter of the slip ring. The standard pressure is 250g/CB and the material is BS. When used for signal purposes, please use it in combination with the BH0804-10/BH0804-12 brush holders and AG0804 (silver-based brush). 【Features】 ■ Compact design ■ Usable regardless of the outer diameter of the slip ring ■ Material is BS *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "V Series" is a brush holder suitable for medium-capacity current supply. The material is BS, and "V-50" is suitable for use with diameters from Φ75 to Φ120, while "V-60" is suitable for diameters from Φ125 to Φ170, within a ring outer diameter of Φ75 to Φ170. Please use according to your application. 【Lineup】 ■V-50 ■V-60 *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "BHR Series" is a holder rod designed for mounting the brush holders of the S, B, and V series. The insulating part is made of glass epoxy material. We offer options such as "BHR-10100G" with a pitch of 6×1.0 and "BHR-12100G" with a pitch of 8×1.25. Additionally, we can manufacture holder rods that are not standard products. 【Features】 ■ For securing brush holders of the S, B, and V series ■ Insulating part made of glass epoxy material ■ Custom holder rods can also be manufactured *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "shrink-fit type / assembly type" is a slip ring widely used in winding motors. The "shrink-fit type" ensures that there is no loosening of the slip ring due to the shrink-fitting of the boss body and slip ring, achieved through years of experience and technology, allowing for long-term use. The "assembly type" is designed for large diameter, multi-pole, and special-shaped slip rings that cannot be manufactured using molding or shrink-fitting methods. 【Shrink-fit Type Features】 ■ No loosening of the slip ring at all due to years of experience and technology ■ Long-term use is possible ■ Usable for high-speed rotation in motors and other applications *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our molded slip rings use a premix material that excels in heat resistance and insulation. In particular, by integrating the terminal section into a single mold, we offer products that are free from loosening and contact failure. We have a lineup that includes "2-pole molded types" suitable for powering single-phase AC/DC small motors, as well as "3-pole molded types" and "4-pole molded types." 【Features】 ■ Uses a premix material that excels in heat resistance and insulation ■ The terminal section is molded as a single piece, eliminating loosening and contact failure ■ We manufacture molded products tailored to customer needs for lighting, packaging, industrial equipment manufacturers, etc. ■ Low prices ■ Immediate delivery system *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Essential for powering rotating bodies: that is the slip ring system (collecting device). In recent years, the advancements in various industrial machines have been truly remarkable, following a path of increasing complexity and sophistication. The slip ring system plays a crucial role in alleviating this complexity. Based on years of experience and technology, our company continues to make unceasing progress to meet the needs of our users and further establish trust.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

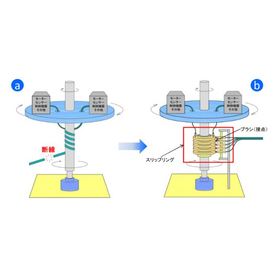

Essential for power supply to rotating bodies: that is the slip ring system (collecting device). ■ In the case of lead wires (without using slip rings) When wiring from the rotating side to the fixed side for equipment on the rotating body using lead wires as usual, there is a risk of disconnection due to twisting of the lead wires or entanglement with the shaft, as shown in the diagram above. ■ Using a slip ring system By using a slip ring system between the rotating side and the fixed side, power supply and data communication can be conducted without twisting of the wiring or entanglement with the shaft, as shown in the diagram above. The example in the diagram is a usage case with a rotating side slip ring and a fixed side brush holder.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Essential for powering rotating bodies: that is the slip ring system (collecting device). ■ In the case of lead wires (without using slip rings) When wiring from the rotating side to the fixed side using lead wires as usual for equipment on the rotating body, there is a risk of disconnection due to twisting of the lead wires or entanglement with the shaft, as shown in the above figure. ■ Using a slip ring system By using a slip ring system between the rotating side and the fixed side, power supply and data communication can be performed without twisting the wiring or entangling with the shaft, as shown in the above figure. The example in the figure shows the use of a rotating side slip ring and a fixed side brush holder.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Essential for power supply to rotating bodies: that is the slip ring system (collecting device). ■ In the case of lead wires (without using slip rings) When wiring from the rotating side to the fixed side using lead wires as usual for equipment on the rotating body, there is a risk of disconnection due to twisting of the lead wires or entanglement with the shaft, as shown in the figure above. ■ Using a slip ring system By using a slip ring system between the rotating side and the fixed side, power supply and data communication can be performed without twisting of the wiring or entanglement with the shaft, as shown in the figure above. The example in the figure above shows usage with a rotating side slip ring and a fixed side brush holder.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The SRC120-20A series can handle power up to 20A. It can also be used for a wide range of applications, including signals and small currents. By using special alloy brushes, it achieves a long lifespan of 60 million rotations. 【Features】 ■ Compact yet capable of handling power up to 20A! Supports various applications such as signals and small currents! ■ Achieves reduced running costs with a long lifespan of 60 million rotations! ■ Customizable to accommodate compensation leads, making it compatible with temperature sensors! ■ Communication cables can be integrated, allowing for combined use with power!

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Essential for powering rotating bodies is the slip ring system (collecting device). In recent years, the advancements in various industrial machines have been truly remarkable, following a path of increasing complexity and sophistication. The slip ring system plays a crucial role in alleviating this complexity. Based on years of experience and technology, our company continues to make unceasing progress to meet the needs of our users and to further establish trust.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration