It is ideal for semiconductor manufacturing equipment, roll heaters, packaging machines, etc. Its outstanding longevity also contributes to cost reduction.

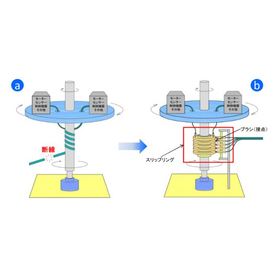

Essential for power supply to rotating bodies: that is the slip ring system (collecting device). ■ In the case of lead wires (without using slip rings) When wiring from the rotating side to the fixed side for equipment on the rotating body using lead wires as usual, there is a risk of disconnection due to twisting of the lead wires or entanglement with the shaft, as shown in the diagram above. ■ Using a slip ring system By using a slip ring system between the rotating side and the fixed side, power supply and data communication can be conducted without twisting of the wiring or entanglement with the shaft, as shown in the diagram above. The example in the diagram is a usage case with a rotating side slip ring and a fixed side brush holder.

Inquire About This Product

basic information

**Features** 〇 Number of poles 4, 6, 8P 〇 Voltage Below 200V 〇 Allowable current Below 15A, thermocouple, signal 〇 Allowable rotation speed 800rpm 〇 Outer diameter φ55 〇 Insulation resistance Above 50MΩ (500V) 〇 Insulation strength 1500V/min 〇 Rotation lifespan 30 million rotations (maintenance-free) 〇 Contact resistance Below 50mΩ 〇 Peak noise Below 5mΩ 〇 Rotation direction CW - CCW ● For other functions and details, please contact us.

Price information

-

Delivery Time

Applications/Examples of results

【Usage】 〇 Used for power supply to rotating bodies. ● For other functions and details, please contact us.

catalog(1)

Download All CatalogsCompany information

In recent years, the advancements in various industrial machinery have been truly remarkable, following a path of increasing complexity and sophistication. A key player in alleviating these complex functions is the slip ring system. Based on years of experience and technology, our company continues to make unceasing progress to meet the needs of our users and further establish trust.

![Electrical products EMC testing [BCI test] optical fiber transceiver](https://image.mono.ipros.com/public/product/image/5f3/2000055367/IPROS5542315369975789883.jpg?w=280&h=280)