1~21 item / All 21 items

Displayed results

Filter by category

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Contact this company

Contact Us Online1~21 item / All 21 items

Filter by category

In offices and call centers, the accumulation of stress and fatigue can lead to decreased work efficiency and employee turnover. However, it is not easy to notice changes in employees during daily operations. The high-precision stress analysis system "Anzen-kun" is an AI system that analyzes voice and facial expressions to understand the state of employees. It incorporates emotion analysis technology (developed by Emotional Technologies Inc.) that has also been utilized in the recently discussed "AI Akimoto Yasushi." ■ Main Features - Available by simply answering three questions at the start of work or after breaks - Analyzes voice and facial expressions to grasp the state - Quantifies 40 categories of emotions in about 15 seconds - Displays results for individuals and teams on a dashboard - Notifies administrators if any anomalies are detected - Usable with just one tablet, no paper or surveys required "Anzen-kun" can be easily integrated into daily operations and serves as an aid in creating a more comfortable work environment.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the medical and caregiving fields, staff stress and fatigue can not only impact work performance but also contribute to turnover and labor shortages. However, it is not easy to notice changes in staff amidst the daily busyness. The high-precision stress analysis system "Anzen-kun" is an AI system that analyzes voice and facial expressions to understand the condition of staff. It incorporates emotion analysis technology (developed by Emotional Technologies Co., Ltd.) that has also been used in the recently discussed "AI Akimoto Yasushi." ■ Main Features - Can be used by simply answering three questions before work or during shift changes - Analyzes voice and facial expressions to assess condition - Quantifies 40 types of emotions in about 15 seconds - Displays results for individuals and teams on a dashboard - Notifies administrators if any anomalies are detected - Usable with just one tablet, no paper or surveys required "Anzen-kun" can be easily integrated into daily operations and serves as a tool to support staff health management and mental care.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the transportation industry, a driver's physical condition and mental health issues can lead to accidents. Particularly during long hours of driving or night shifts, it is a challenging task to assess their condition based on appearance. The emotional analysis technology used in the recently discussed "AI Akimoto Yasushi" (developed by Emotional Technologies Inc.) is incorporated here. The high-precision stress analysis system "Anzen-kun" is an AI system that analyzes voice and facial expressions to understand the condition of crew members. ■ Main Features - Can be used by simply answering three questions during pre-duty roll call - Analyzes voice and facial expressions to assess condition - Quantifies 40 types of emotions in about 15 seconds - Displays results on a dashboard for individuals and teams - Notifies administrators if any abnormalities are detected - Usable with just one tablet, no paper or questionnaires required "Anzen-kun" streamlines the process of checking crew members' conditions and can be utilized as an aid for safety management in transportation settings.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The construction site is an environment fraught with danger, and the physical and mental health of workers can lead to accidents. However, it is difficult to make judgments based solely on appearances. The high-precision stress analysis system "Anzen-kun" is an AI system that analyzes voice and facial expressions to understand the condition of workers. It incorporates emotion analysis technology (developed by Emotional Technologies Co., Ltd.) that was also used in the recently popular "AI Akimoto Yasushi." ■ Main Features - Can be used simply by answering three questions during morning meetings - Integrates and analyzes voice and facial expressions - Quantifies 40 categories of emotions in about 15 seconds - Displays results for individuals and teams on a dashboard - Notifies administrators if any abnormalities are detected - Usable with just one tablet, no paper or questionnaires required "Anzen-kun" can be seamlessly integrated into daily operations as an aid for safety management on construction sites.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In manufacturing sites, employees' physical condition and mental health issues during machine operation and line work can lead to accidents and quality defects. However, it is a challenging task to judge based solely on appearances. The high-precision stress analysis system "Anzen-kun" is an AI system that analyzes employees' voices and facial expressions to understand their condition. It incorporates emotion analysis technology (developed by Emotional Technologies Inc.) that was also utilized in the recently popular "AI Akimoto Yasushi." ■ Main Features - Can be used by simply answering three questions before shift changes - Integrates and analyzes voice and facial expressions - Quantifies 40 categories of emotions in about 15 seconds - Displays results at both individual and team levels on a dashboard - Notifies administrators if any anomalies are detected - Usable with just one tablet, no paper or questionnaires required "Anzen-kun" can be seamlessly integrated into daily operations as an auxiliary tool to prevent accidents and troubles in manufacturing sites.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Equipped with emotion analysis technology (developed by Emotional Technologies Inc.) that has also been utilized in the recently popular "AI Akimoto Yasushi." The high-precision stress analysis system "Anzen-kun" is an AI solution that analyzes emotional states based on voice and facial expressions, allowing for early detection of signs of risk lurking in the workplace. ■ Main Features - Analyzes voice and facial expressions by simply answering three questions - Scores stress and anxiety in about 15 seconds - Integrates voice and facial expressions to analyze 40 categories of emotions - Usable with just one tablet, no paper or questionnaires required - Allows for checking analysis results for individuals or teams on a dashboard - Notifies administrators in case of abnormalities It is expected to be utilized in various fields such as construction, manufacturing, healthcare, and transportation, serving as a support for accident prevention and employee retention. It is equipped with an emotion analysis engine based on research achievements and can be seamlessly integrated into daily operations.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

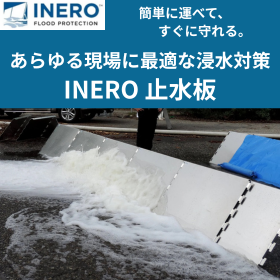

INERO is a reusable flood barrier that originated in Sweden and has gained trust across various parts of Europe. It stands independently by simply connecting units together, allowing for the rapid establishment of a flood protection line in a short amount of time. It can be deployed by a small team of 2 to 4 people and is effective for emergency responses during sudden heavy rain or at night. It can be installed not only as a preventive measure before flooding occurs but also after flooding has begun. Compared to traditional sandbags, it can be set up overwhelmingly faster, preventing operational shutdowns and asset damage. This flood prevention solution, which is now being introduced in Japan, will protect factories, warehouses, commercial facilities, and local government sites.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

INERO is a reusable flood barrier developed in Sweden, widely adopted by municipalities and government agencies across Europe. Its quick connector system allows for long-distance deployment, enabling immediate response during road flooding or river overflow. Being reusable makes it economically viable for disaster preparedness, and it generates very little waste. Flexible layouts are possible with corner and end units, making it suitable for training with fire and water utility operators. In recent years, with the frequent occurrence of torrential rains in Japan, flood prevention measures have become crucial. The introduction of INERO's flood barriers provides a new option for local disaster prevention.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

INERO is a Swedish-made reusable water barrier that is adopted in factories and logistics hubs across Europe. It stands independently by simply connecting the units, allowing for quick installation by a small number of people in a short amount of time. After flooding, it can be cleaned and reused, reducing environmental impact as no waste is generated. Compared to traditional sandbags, it offers rapid and efficient installation and removal, significantly alleviating the burden on site. It is utilized to prevent flooding in front of factory and warehouse shutters, as well as at loading entrances, minimizing operational downtime and damage to inventory assets. This water barrier has now begun its rollout in Japan. As the latest flood prevention solution, it protects industrial sites from sudden heavy rains and internal flooding.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

INERO is a reusable water barrier originating from Sweden, and it is being implemented in disaster prevention sites across various European countries. Installation requires no tools and can be done in a short time with a small number of people. After flooding, it can be collected, cleaned, and dried for repeated use, achieving significant cost savings and reduced environmental impact compared to traditional sandbags. By starting its introduction in Japan, it presents a valuable opportunity to incorporate the latest European disaster prevention technology. It is ideal for factories, logistics centers, and municipal disaster preparedness stockpiles, and it is a groundbreaking product that brings sustainable flood prevention measures to Japan.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The INERO water barrier was developed in Sweden and is a reusable water barrier adopted in various parts of Europe. It stands independently by simply connecting the units on the ground, eliminating the heavy labor associated with traditional sandbag work. After flooding, it can be cleaned and reused, achieving both waste reduction and cost savings. This trusted solution, which has been active in European government offices, factories, and logistics facilities, will also be introduced in Japan. It protects a wide range of locations, such as in front of factory and warehouse shutters and entrances to commercial facilities, from sudden heavy rain and internal flooding.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

INERO is a reusable water barrier developed in Sweden, with a proven track record of implementation in various European countries. It requires no tools and can be installed simply by connecting units, using water pressure to stand independently, forming a strong water barrier line with a small number of people in a short time. After flooding, it can be collected, cleaned, and dried for repeated use, achieving both waste reduction and cost savings compared to traditional sandbags. It has already been adopted by EU government agencies, municipalities, factories, and logistics facilities, and is being utilized to prevent road flooding, river flooding, and flooding in underground facilities. Not only in Europe but also in Japan, it has started to be deployed as a groundbreaking flood prevention solution, reducing the risk of operational shutdowns in factories, warehouses, and commercial facilities, and serving as an immediate asset for local disaster prevention in municipalities. In preparation for sudden heavy rains and urban flooding, proven technology from Europe is being brought to Japan!

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In outdoor work in cold regions, visibility of the camera is obstructed by snow, frost, ice, and condensation, requiring removal through warm air or manual efforts, which significantly reduces work efficiency. ■ Solution: The Power of TOUGHEYE-1700 The TOUGHEYE-1700, designed to withstand temperatures as low as -40°C, features a unique physical cleaning structure that removes only the contaminants without scraping off ice or snow. It maintains clear images even in cold regions. ■ Key Features -40°C operation, resistant to condensation and frost Self-removing design that does not rely on heaters Robust structure that continuously maintains clear visibility Maintenance-free (no cleaning required)

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In processing and manufacturing sites, lenses often fog up due to oil smoke and mist, making camera images unusable. Frequent cleaning is labor-intensive and can become a critical issue for unmanned lines and AGVs. **Solution: The Power of TOUGHEYE-1700** Even when oil and mist adhere, its unique self-cleaning structure automatically cleans the lens surface physically. No cleaning is required, maintaining visibility even during operation and enabling stable monitoring without stopping the line. **Main Features** - Special surface structure that removes oil and mist - No need for water, detergent, or air - Minimizes line stoppage and zero cleaning effort - Easy installation with an integrated design, robust and highly durable construction

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

At harbor facilities and coastal installations, corrosion and fogging of cameras frequently occur due to salt and humidity condensation. Every time the lens becomes obscured, work has to be stopped for cleaning... The TOUGHEYE-1700 is here to solve the stress of such environments. This product features a unique structure that physically removes dirt without using water, detergent, or air. With no external mechanisms, it maintains visibility even when exposed to salt and condensation. It is highly resistant to high humidity, sea breezes, and condensation, making it ideal for salt-damaged areas. ■ Main Features Durability against humidity, condensation, and salt Zero cleaning work with automatic cleaning Suitable for long-term operation outdoors and along coastlines.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In construction, mining, agriculture, and other fields, mud and dust can quickly obscure the camera's view. Each time the lens gets dirty, it requires manual cleaning, causing work to pause. Isn't it time to put an end to the inefficiencies and dangers that have become the norm on site? The TOUGHEYE-1700 is a self-cleaning integrated camera that removes mud, dust, and debris on its own. Whether at heights or in hazardous areas, workers no longer need to go clean the camera. With a durability of 40,000 washes and a completely sealed structure, it provides a clear view at all times. ■ Key Features - Self-removal of mud and dust that adheres to the view - MIL-standard vibration-resistant design, IP69K waterproof and dustproof - Harsh environment performance compatible with -40℃ - Maintenance-free (40,000 wash durability)

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Excelsense Self-Cleaning Camera" is an industrial camera series that maintains a clear view in harsh industrial environments. Equipped with patented active self-cleaning technology, it can clear dirt such as oil, mud, salt, and dust from the lens surface at any desired time. There is no need to replace liquids, reducing cleaning effort and contributing to improved safety and work efficiency. Additionally, the retrofittable "SENSERSHIELD" is compatible with existing equipment. 【Features】 ■ Three models available: integrated, retrofittable, and LiDAR compatible * The LiDAR compatible model is scheduled to be released by the end of 2025. ■ Fully automatic, no cleaning required, reducing maintenance costs (TOUGHEYE-1700, SENSERSHIELD-1600) ■ Designed to withstand extreme cold (-40°C), 30G vibration, and 100G shock (TOUGHEYE-1700) ■ The retrofittable "SENSERSHIELD" is compatible with existing equipment * For more details, please refer to the materials. Feel free to contact us with any inquiries. * This product is handled by Syon Co., Ltd., a member of the Seikun Group.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is a self-cleaning unit for LiDAR sensors. ■ Scheduled to begin sales within 2025 ■ Equipped with patented ClearSight technology, it automatically removes dirt caused by oil, mud, dust, and snow. It offers high durability and reliability, requires no maintenance, and consistently delivers sensor performance. Compatible with major LiDAR sensors such as Ouster OS0/OS1, it allows for cleaning control via timer or electrical trigger. It contributes to the stable acquisition of sensor data in harsh environments such as outdoor work, autonomous driving, ports, mines, and smart infrastructure. In environments where precise sensing is required, such as autonomous driving and robotics, it minimizes the impact of dirt. ■ Key Features: - 50,000 cycles of durable cleaning performance - Environmentally compliant with MIL-STD-810G - Operates in temperatures from -40°C to 60°C, IP69 dust and waterproof - Retrofit design allows for the use of existing LiDAR systems *This product is currently undergoing continuous improvement and development regarding some specifications and performance. There may be changes to detailed specifications in pursuit of higher reliability and practicality. Please contact us for the latest information.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Excelsense Self-Cleaning Camera" is an industrial camera series that maintains a clear view in harsh industrial environments. Equipped with patented active self-cleaning technology, it can clear dirt such as oil, mud, salt, and dust from the lens surface at any desired timing. The frequency of cleaning can be freely set, allowing for operation tailored to the environment! There is no need to replace cleaning agents, reducing the hassle of maintenance and contributing to improved safety and work efficiency! ▶▶ This is a standalone self-cleaning unit product that can be retrofitted to existing cameras and sensors. It is designed for those who are already using cameras or sensors and do not want to change them (please inquire whether it can be installed on your existing camera). 【Recommended Installation Sites】 ■ Areas for mounting construction machinery and outdoor equipment ■ Infrastructure monitoring points such as bridges and tunnels ■ Automated lines and areas around robots within factories ■ Surroundings of outdoor security and surveillance cameras *For more details, please refer to the related links or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "Excelsense Self-Cleaning Camera" is an industrial camera series that maintains a clear view in harsh industrial environments. Equipped with patented active self-cleaning technology, it can clear dirt such as oil, mud, salt, and dust from the lens surface at any desired timing. The frequency of cleaning can be freely set, allowing for operation tailored to the environment! There is no need to replace cleaning agents, reducing the hassle of cleaning and contributing to improved safety and work efficiency! 【Recommended Sites for Installation】 ■ Construction sites and heavy machinery work areas ■ Outdoor work areas at port facilities and on vessels ■ Dusty environments such as mines and quarries ■ Monitoring areas of outdoor factories and logistics hubs *For more details, please refer to the related links or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"EXCELSENSE" is an advanced self-cleaning camera series born in Canada. With active self-cleaning technology, it automatically removes tough dirt such as oil, mud, and salt. Even in extremely cold environments or dusty sites, it maintains a clear view at all times, significantly enhancing the reliability of monitoring and sensing. No maintenance required, high durability, and cost-effective. This is a solution we want to introduce in harsh environments. 【Features】 ■ Detects dirt and cleans automatically ■ No refills or replacements needed, maintenance-free ■ Operates in temperatures as low as -40°C and withstands up to 100G, designed for harsh environments *For more details, please refer to the related links or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration