Revolution in Parts Counting for the Manufacturing Industry! A Complete Guide to Counting Automation Realized with AI-Equipped Parts Counters.

Introduction: Challenges Faced by Counting Operations in Manufacturing Sites

Manufacturers, do you face any troubles with daily parts management or production management?

"Although we use counters for screws, bolts, and nuts, the accuracy is insufficient." "Counting parts manually takes too much time." "Weight-based counters do not function accurately for parts with individual differences." "We want to use it for picking with a target value of around 100 pieces." "Due to the Toyota Production System, the number of bags for individual packaging is small."

Mistakes in counting operations in manufacturing can lead to losses amounting to hundreds of millions of yen annually. Especially in recent years, due to labor shortages, conducting high-precision parts quantity counting with limited personnel has become an urgent issue for many manufacturing sites. Even if you are considering introducing a picking counter, many may be unsure about which counting machine to choose.

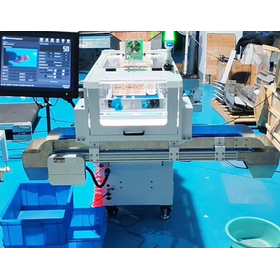

Rest assured. With the latest AI-equipped camera-based parts counters, these challenges can be dramatically improved. In this article, we will provide all the necessary information for manufacturers regarding the latest counting machines that utilize image processing technology and AI control, from their mechanisms to how to choose them.

Inquiry about this news

Contact Us OnlineMore Details & Registration

Details & Registration

Related Documents

Related Links

Please take a look at the camera-style parts counter.