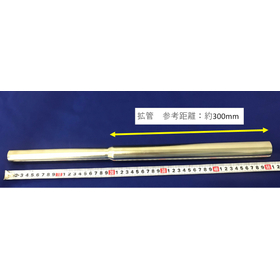

Pipe expansion and contraction (punch processing) achieves a longer processing distance than conventional methods!

This is a product of pipe expansion and contraction using a punching process. We have achieved a longer processing distance than conventional methods without using hydraulic forming. While hydraulic forming is a method that does not cause molding defects for long-distance pipe expansion and contraction, it requires specialized molding equipment, resulting in high production costs, and necessitates sealing liquid or gas inside the pipe during the forming process.

Our pipe expansion and contraction processing using the punching method eliminates these issues and allows for processing at a lower cost. Of course, bending after processing is also possible.

Inquiry about this news

Contact Us Online