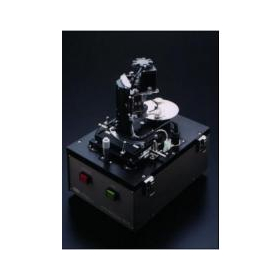

Easily detect metal cracks with your eyes and ears. Lightweight and compact eddy current flaw detector.

The Crack Tester CT-121/CT-3 is a revolutionary eddy current flaw detector designed to be lightweight and compact. Traditional eddy current flaw detectors require specialized knowledge and techniques such as phase difference and vector analysis, but the CT-121/CT-3 allows anyone to easily confirm cracks using just the meter's fluctuations and the sound from the headphones. In terms of performance, it achieves unprecedented high sensitivity with a newly developed sensor, making it possible to detect fine cracks that were previously difficult to identify. Additionally, measurements can be taken without removing paint, and non-contact measurements are also possible. It is compatible with all metals, from steel to stainless steel and non-ferrous metals like aluminum.

Inquire About This Product

basic information

■Features - Highly sensitive detection of microscopic cracks in metals - Easy to catch with meter fluctuations and earphone sounds - Measurement possible without removing paint - Non-contact measurement available - Built-in battery - Compatible with all metals from steel to SUS and aluminum

Price range

Delivery Time

Applications/Examples of results

■Usage CT-3: Compatible with all metals CT-121: For steel materials only CT-121N: For non-ferrous materials only CT-121S: For SUS (stainless steel) only

catalog(2)

Download All CatalogsCompany information

We provide non-destructive testing equipment for various applications, including measuring bolt axial force using electromagnetic force, crack detection using eddy current testing, checking for hardening in heat-treated parts, material differentiation, and material identification. We have also started selling a new product, the nickel plating thickness SN-2000N.