A collection of machining case studies from Hirokawa Manufacturing, a company specializing in precision cutting of resin (plastic).

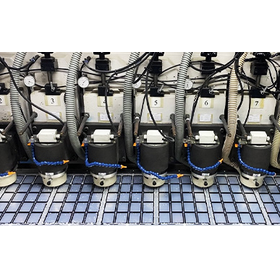

Hirokawa Manufacturing Co., Ltd. specializes in the cutting and processing of resin (plastic) materials. We excel in the precise and delicate processing of plastic parts for semiconductor-related components, medical devices, and transport parts. We have accumulated a wealth of experience in tools and processing methods suitable for various plastic materials, allowing us to accommodate a wide range of resins. We have established a system that can handle small lot, diverse products that would be costly to mold, as well as prototypes before molding, processing from a single piece. The "Hirokawa Manufacturing Co., Ltd. Synthetic Resin Cutting Processing Case Studies" contains numerous examples of our original processing samples. [Featured Products] ○ Fluororesin ○ Acrylic ○ Polypropylene ○ PEEK ○ Unilate, and others For more details, please contact us or download the catalog.

Inquire About This Product

basic information

【Featured Products】 ○ Fluororesin (4F, 3F, 2F, 1F) ○ Acrylic (PMMA) ○ Polypropylene (PP) ○ PEEK ○ Unilate (G-PET) ○ Polyacetal (POM) ○ Polyvinyl Chloride (PVC) ○ MC Nylon (MC) ○ Ultra High Molecular Weight Polyethylene (U-PE) ○ Sumika Super (LCP) ○ Polyimide (PI) ○ Polyamide Imide (PAI) ○ Machinable Ceramics ○ Others ● For more details, please contact us or download the catalog.

Price information

Please contact us.

Delivery Time

※Please contact us.

Applications/Examples of results

For more details, please contact us or download the catalog.

catalog(1)

Download All CatalogsCompany information

At Hirokawa Manufacturing Co., Ltd., we perform resin cutting and plastic processing using machining, composite processing machines, and NC lathes, working with a variety of general-purpose plastics to super engineering plastics. We specialize in precision machining of synthetic resin materials for a wide range of applications, including semiconductor-related resin parts, LCD-related resin parts, and chemical tank manufacturing. We excel in more complex processing and manufacturing using multi-axis simultaneous processing machines, allowing us to meet various customer needs. We have established a system to accommodate special processing that cannot be done by other companies, so please feel free to contact us for quotes or prototypes.

![Cutting processing of PBI resin [SPR7900 Alloy Natural Grade]](https://image.mono.ipros.com/public/product/image/a08/2001484004/IPROS74531377335574343908.png?w=280&h=280)

![Attention those struggling with deadlines! Resin prototype production [machining processing]](https://image.mono.ipros.com/public/product/image/9e9/2000660272/IPROS08309818705906898772.jpeg?w=280&h=280)

![Quality Control Analysis of Polyols Using Near-Infrared Analyzers [Technical Document]](https://image.mono.ipros.com/public/product/image/df6/2000514127/IPROS36236993201032646122.jpeg?w=280&h=280)