For process development, optimal plant design, and operational optimization studies! Simulators for the oil, gas, and chemical industries.

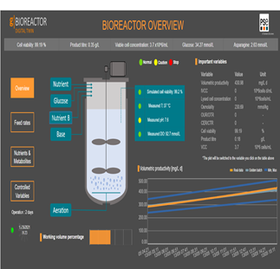

In plant design, equipment sizing, process consideration, and operational optimization, PSE believes that existing process simulators still have room for improvement in terms of convergence for obtaining numerical solutions, constraints of processes they can handle, and customization of process models (model extensibility). The process simulation software developed to meet the needs for more advanced and value-added process plant design and optimization is 'gPROMS Process'. 【Features】 * Libraries for specific applications * Creation of flow sheets using Drag & Drop * High-precision custom model creation and editing functions using gPROMS language * Changes in settings within the same environment from steady-state simulation models to dynamic simulation models * Powerful optimization solution search and analysis functions * Global System Analysis (GSA) * High-Performance Computing (HPC) ★ You can view two "case study materials" available for download. These include examples of achieving high-value product offerings and cost reduction through batch process optimization, as well as successful cases of cost reduction through the optimization of entire plants.

Inquire About This Product

basic information

We have libraries for each application. AML: Fixed-Bed Catalytic Reactor AML: Trickle-Bed Reactor AML: Gas-Liquid Contactors gML: Separations - Adsorption gML: Separations - Membranes gML: Utilities gML: Water Activated Sludge gML: Olefins *For more details, please refer to the materials. We regularly conduct free training sessions regarding this product. Anyone interested is welcome to participate.

Price information

You can contract on a monthly basis.

Delivery Time

P3

※Delivery date after contract signing

Applications/Examples of results

1. PSA (Pressure Swing Adsorption) PSA is essentially a dynamic process, and this software can be considered an ideal tool for it. The definition of the operating cycle and the description of the valve opening and closing schedule are also taken into account to allow input from the scheduling GUI. The SIB (Self-Interacting Bed) model is a single adsorption column model that serves as a mechanism to represent PSA processes involving multiple adsorption columns, enabling efficient calculation of cyclic steady states, making it a convenient approach for solving optimal design problems in PSA. 2. Examination of Hybrid Separation Processes In the design of composite processes that combine membrane separation and PSA processes, the membrane model and adsorption column model included in gML allow for rapid and detailed examination of composite processes. 3. Sensitivity Analysis of Gas Separation Process Design This accommodates processes that include multiple distillation columns and multiple recycle streams.

catalog(17)

Download All CatalogsNews about this product(32)

Company information

Founded in 1997 by the gPROMS development team at Imperial College London, PSE became part of the Siemens Group in 2019 and has been providing products and services in Japan as Siemens Corporation since 2023. gPROMS features a powerful equation-based computation engine that differs from traditional simulators, allowing for seamless handling of both steady-state and dynamic simulations. This enables the effective scaling up of models adjusted with experimental data from batch processing for the design and operational optimization of continuous processing plants. With gPROMS's excellent capabilities in custom modeling, parameter estimation, and optimization, it is possible to quickly build optimal manufacturing processes, resolve issues, and achieve optimization.

![[Example] Thermal conduction and thermal stress coupled analysis of circuit boards 'AIFEM'](https://image.mono.ipros.com/public/product/image/723/2001511716/IPROS11750362110857641542.PNG?w=280&h=280)

![[Example] Frequency Response Analysis of Electrical Box 'AIFEM'](https://image.mono.ipros.com/public/product/image/eb4/2001511718/IPROS17014576216344480199.PNG?w=280&h=280)

![Understand in 3 minutes! What you can do with a manufacturing simulator [Materials Provided]](https://image.mono.ipros.com/public/product/image/10f/2001482625/IPROS15916837536830497441.jpg?w=280&h=280)