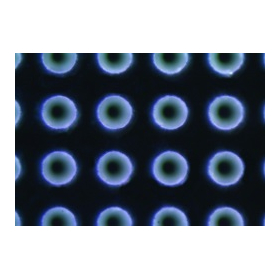

This is an introduction to examples of processing techniques for ultra-fine metal pipes, including one-sided through-hole machining, porous machining, slitting, groove machining, spiral groove machining, and notch machining.

It has become possible to perform various fine processing on thin, ultra-fine metal pipes that were previously unable to be processed due to deformation from external forces with contact tools and thermal effects with conventional thermal processing lasers. By using a rotating mechanism, it is possible to carry out processing in all rotational directions.

Inquire About This Product

basic information

1. Due to non-thermal processing with ultrashort pulse lasers, it is possible to achieve processing without burrs, molten material, or thermal distortion. 2. Processing is possible regardless of the material or type of metal. 3. It is possible to flexibly adjust hole diameter, groove width, direction, depth, and other parameters.

Price range

Delivery Time

Applications/Examples of results

Medical devices related, semiconductor related

Company information

At Lips Works Co., Ltd., we provide contract micro-fine processing using ultra-short pulse lasers, as well as the design and manufacturing of laser systems. In our contract processing business, we have been quick to engage in the development of industrial ultra-short pulse lasers and have been involved in contract micro-fine processing using these lasers. We specialize in applying fine periodic structures (microtextures) to work surfaces aimed at controlling tribological properties, optical properties, and release/adhesion characteristics. We can accommodate requests from small-scale prototypes to mass production according to our customers' needs. In our system engineering business, we leverage the laser processing technology cultivated in our job shop to provide a comprehensive service from selecting laser oscillators suitable for applications, designing optical systems, devising fixtures and auxiliary equipment, to system integration. We assist in improving the precision and efficiency of the processing required by our customers. As experts in laser technology providing cutting-edge laser processing techniques, we strive to be a valuable resource for our customers, so please feel free to contact us.

![[Insulation Material Processing Example] Fineflex BIO Board Large Diameter Split](https://image.mono.ipros.com/public/product/image/2069787/IPROS9402177492004993539.png?w=280&h=280)