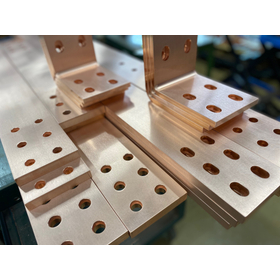

Knowledge for Selecting Copper Bars (Main Bars and Branch Bars): Reducing processing costs and overall cost reduction!

【Before】 When determining the dimensions of copper bars used for carrying large currents, such as in power distribution boards, there were no clear internal standards, and we were directly repurposing from past drawings. The large cross-sectional area copper bars were not standard products from manufacturers, and we were ordering them as custom items each time, which led to high material costs for copper and processing costs for specified dimensions, becoming a problem. ↓ 【After】 The key points for selecting custom copper bars are that referring to the size charts from material manufacturers can help reduce processing costs. Since the dimensions of copper bars intended for carrying current do not require high precision in material dimensions, it is efficient to design them to match the original material dimensions as closely as possible. Although there is a standard length for each material, determining the dimensions of copper bars that do not require complex machining can achieve cost reductions. *For more details, please refer to the catalog or feel free to contact us.*

Inquire About This Product

basic information

**Effect** Among the accessories and parts, excluding electrical and control equipment used on the board, the cost ratio of copper bars is very high. Therefore, reducing the cost of copper bars (the larger the capacity of the copper bars, the more significant the impact) will achieve an overall cost reduction. *For more details, please refer to the catalog or feel free to contact us.*

Price range

Delivery Time

Applications/Examples of results

For more details, please refer to the catalog or feel free to contact us.

catalog(2)

Download All CatalogsCompany information

Hoshimoto Co., Ltd. is a manufacturer that has been producing and selling industrial handles, locks, hinges, handles, copper busbars, and pressed, machined, and cast products for control panels, cubicles, and distribution boards since its establishment. Leveraging the characteristics of manufacturing and sales, we are committed to product development with the motto of creating what is needed. In addition to standard catalog items, we also respond to commissioned processing based on our available equipment (press machines, benders, NC lathes, machining centers, header machines, zinc die casting, milling machines, etc.) as needed. We have obtained ISO 9001:2000 and ISO 14001 certification.