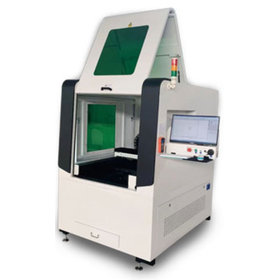

This is a press processing machine with optimal mechanical design that achieves long lifespan, high reliability, low maintenance, and high precision.

It is possible to introduce a used press machine from Fine Tool Company at a low cost. If you are interested, please feel free to contact us. ■ Equipped with material supply devices from Japanese manufacturers Long lifespan, high reliability, low maintenance Optimal mechanical design for high precision High rigidity integrated cast frame, vibration absorption Preload 0 clearance slide guide Resistant to centralized loads Slide drive mechanism: high energy efficiency, low maintenance AC servo motor drive, bearing-equipped double knuckle lever mechanism ■ Safety first: Protection for operators, molds, and presses Separation and discharge of products and scrap (air blow and others) Operator protection, safety doors, soundproof cases Tool safety system (patented) ■ FMC (Fine Tool Motion Control) Control of slide, air blow, head/table, material feeding, material release, mold production data, etc. Controlled by high-performance industrial PC OS: Windows SPS software (for automation and machine control) Fieldbus (I/O communication with other devices)

Inquire About This Product

basic information

■ Simple M&M Interface Production data and mold data memory M&M Interface (Swing-arm type color monitor touch screen, input, monitoring, messaging, language switching) Error diagnosis & troubleshooting (remote diagnosis, equipment scopes, etc.) ■ High productivity/reliability AC servo motor drive, double knuckle lever mechanism for slide pot bottom curve Improvement of mold life and high precision of parts through optimal slide motion ■ Space-saving: Sufficient die area Universal die area, compatible with various concept molds (Fixed/movable combination tables, single and progressive molds) Easy mold changeover, use of existing molds Compact design, easy lineup with coil lines, floor mount

Price range

Delivery Time

Applications/Examples of results

For more details, please contact us.

catalog(1)

Download All CatalogsCompany information

Fine Tool Japan started in 1973 as a sales company for fine blanking press machines (FB presses). Initially, it was primarily accepted as a manufacturing technology for office machine parts, but due to the improvement of press machines and precision mold processing technology, as well as the needs for high added value and cost reduction in the manufacturing industry, it developed into the production of automotive parts and is widely utilized in the manufacturing of machine parts. Currently, it serves as the technical center for the Fine Tool Group in Asia, providing total solutions in fine blanking processing.

![35310-6001@640[1].jpg](https://image.mono.ipros.com/public/product/image/141/2000325495/IPROS18498459887524200678.jpeg?w=280&h=280)