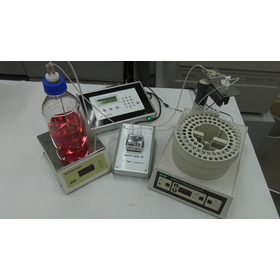

Automatic sampling device for reaction liquid (sampling liquid goes into sterile centrifuge tubes or fraction collectors)

SampleCollecter20

Automating the separation process with sterile compatibility. Automatically sampling reaction liquid from culture tanks and reaction vessels. Transferring the collected liquid to centrifuge tubes and fraction collectors. Videos are currently being streamed on our company website!

Sampling of reaction liquids from reaction tanks, culture tanks, and culture devices has become an important part of process management. By adopting tubing pumps, pinch valves, and PEEK connectors and handy connectors, we have developed a simple and economical sampling device that meets aseptic requirements. We have also developed an aseptic sampling unit for centrifuge tubes. Additionally, we offer bottle caps such as GL-45 to ensure sufficient sterilization measures. The intervals for fractionation can be set between 5 to 250 minutes. Various types of valves can be controlled as an option, allowing for the implementation of different types of fractionation.

Inquire About This Product

basic information

The liquid delivery system consists of a tubing pump, silicone tubing, a pinch valve that does not come into contact with the liquid, and connectors made of PEEK that are compatible with sterilization (autoclaving). For sample collection, we have adopted a uniquely developed sterile remote centrifuge tube collection unit, or the commercially available Bio-Rad Frac-100 (priced under 300,000 yen). A pulse motor is used to drive the tubing pump, achieving highly accurate liquid dispensing. Since everything is developed in-house, it is possible to add various functions. Customization specific to your company's system can be incorporated.

Price range

P4

Delivery Time

P4

Applications/Examples of results

Regular sampling of internal reaction liquid from the culture tank and reaction tank Sampling of solution from the reaction tank Dispensing liquid into the reaction tank

catalog(2)

Download All CatalogsCompany information

We are working on the automation of biotechnology using various technologies. All aspects of hardware design, circuit board design, and software development are carried out with our in-house technology. We are focusing on the development of prototypes and trial machines for bio equipment and process management devices. We can respond flexibly and quickly to customization requests. Our main activities involve collaborative research and development related to bio automation with various research institutes, including RIKEN, and universities. We have accumulated a large library of hardware and software, enabling faster development. We also conduct equipment evaluations using essential reagents for bio equipment development in our unique joint lab at the Toin University Medical Engineering Center. We have extensive development experience in contracted development of new bio equipment for NEDO over many years, as well as custom development of ELISA devices and ELISA washers. Please feel free to contact us regarding the development and prototyping of new equipment. Since we handle all electrical, mechanical, and software development in-house, we specialize in automation of bio equipment, automation of analytical instruments, automation of process management, and protocol development on a custom basis. You can trust us with the development of pneumatic systems such as caps and handy connectors.

![[Patent] Achieving an air nozzle that completely removes water with air blow.](https://image.mono.ipros.com/public/product/image/2116982/IPROS16998950562973190030.png?w=280&h=280)