Sample the brightness values at the same coordinates on the corrected image! Obtain the average and standard deviation σ! This determines the upper and lower limits for the acceptable range!

Visual inspection is a subjective examination. It is important that it aligns with the user's perception. Just like with image sensors, users can evaluate detection capability and operability through actual operation. **Principle** Images captured by digital cameras consist of small clusters of pixels, each having a value ranging from 0 to 255. Positioning is performed on the captured image to align it with the reference image at the same position. By registering good products, the brightness values at the same coordinates are sampled from the image after position correction. This sampling allows for the acquisition of the average and standard deviation σ. Based on rules such as "average ± 3σ," the upper and lower limits for the acceptable range of good products are determined. If the brightness or area of a region formed by pixels exceeding the upper (or lower) limit surpasses the set value, it is judged as a defect, and if a defect is present, it is marked as NG (no good). *For more details, please refer to the PDF document or feel free to contact us.*

Inquire About This Product

basic information

For more details, please refer to the PDF document or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

【Suitable Targets】 ■ Items with small product variation (wafers, lead frames) ■ Items with high production quantities (connectors, bolts, nuts) ■ Items that can be inspected without using hands (foreign substances in beverages, labels) ■ Items that can be captured with high-speed imaging (gears, circular saw blades) *For more details, please refer to the PDF document or feel free to contact us.

catalog(1)

Download All CatalogsCompany information

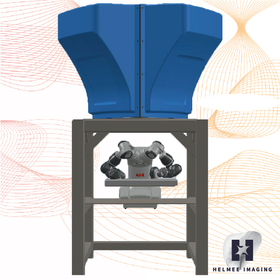

At MJP Corporation, we aim to be your partner company for those considering the automation of visual inspection processes, providing detailed services. Experts in imaging and transportation will assist you in automating the inspection process. If you are considering automating visual inspections (manual inspections) or have had experiences of failure with image inspections, please feel free to consult with us.

![Automatic Appearance Sensor 'FIS-100' [Inspection Method]](https://image.mono.ipros.com/public/product/image/ac1/2000383464/IPROS4377525771301748178.PNG?w=280&h=280)

!["Ping-Pong Method" Automatic Appearance Sensor 'FIS-100' [Patent Pending]](https://image.mono.ipros.com/public/product/image/14f/2000383487/IPROS997412824237906471.PNG?w=280&h=280)

![Gear Inspection Device: Automatic Appearance Sensor 'FIS-100' [Patent Pending]](https://image.mono.ipros.com/public/product/image/2e0/2000383498/IPROS5072474698314768484.PNG?w=280&h=280)

![[Image Processing Achievements Introduction] Image Processing - Inclined Column Device](https://image.mono.ipros.com/public/product/image/b2f/2000409126/IPROS17239753278804509889.png?w=280&h=280)