More like steam than vapor! With the concept of being fluffy, glossy, and delicious.

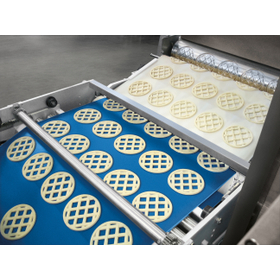

The "Steam Tunnel" is a high-performance steaming machine from AICHI, specializing in the manufacturing of high-quality food machinery, confectionery machinery, and food processing equipment. To create delicious steamed sweets, steam (low-pressure steam) at the same temperature as natural steam (100°C) is essential. AICHI has developed a "low-pressure steam generation system" that maintains a constant internal pressure within the furnace using its unique technology. With the Steam Tunnel that incorporates this system, it is possible to produce steam similar to natural steam, allowing for the mass production of fluffy and delicious steamed sweets. 【Features】 ■ Low-pressure steam generation system ■ Easy quality management system ■ Reliable mold prevention and accident prevention measures ■ Mist spraying device: sprays mist from ultra-fine mist nozzles ■ Paper feeding table: supplies greaseproof paper to be placed under the buns *For more details, please refer to the PDF materials or feel free to contact us.

Inquire About This Product

basic information

【Other Features】 ■ Water wetting device (PAT) ■ In-furnace non-pressure steam generation system (PAT) ■ Three-layer conveyor structure ■ Lift-up mechanism at the top of the main body ■ Condensation countermeasures ■ Others: Connecting equipment such as glassine cup supply device, depositor, product extraction device, branding device, and injector to form an unmanned line before and after the tunnel *For more details, please refer to the PDF document or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

【Applications】 ■ Steamed Buns Line ■ Steamed Manju Line ■ Steamed Cupcake Line ■ Steamed Omelette Line, etc. *For more details, please refer to the PDF document or feel free to contact us.

catalog(1)

Download All CatalogsCompany information

Aichi Electric Heat Co., Ltd. supports our customers in making "delicious sweets and bread" by providing the "optimal production line." We strive to manufacture food machinery that is as simple and functional as possible, and by customizing the width and length of the machines to meet our customers' requests and the space of their production sites, we contribute to improving productivity and quality. We invite confectionery manufacturers and factory owners to feel free to contact us.