Doubling production with robotics: Case study of implementing easily programmable universal robots.

Tegra Medical, a company engaged in metal and machining industries, faced a decline in profit margins due to rising costs and customer demands for price reductions. In response, the company deployed three collaborative robot arms manufactured by Universal Robots. By tending machines that produce medical devices, they doubled their production output and freed up 11 full-time employees, allowing the manufacturer to continue meeting customer demand while keeping costs low. 【Key Points】 - Easy programming - Collaborative and safe - Quick return on investment *For more details, please refer to the PDF document or feel free to contact us.*

Inquire About This Product

basic information

【Tasks Solved by Collaborative Robots】 ■ Machine Tending ■ Pick and Place *For more details, please refer to the PDF document or feel free to contact us.

Applications/Examples of results

For more details, please refer to the PDF document or feel free to contact us.

catalog(2)

Download All CatalogsCompany information

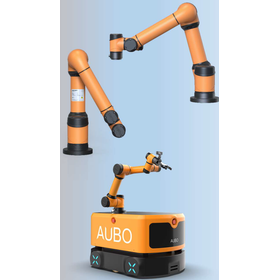

Universal Robots is a pioneer that developed the world's first collaborative robot and is a leading company in the field of collaborative robots. Equipped with safety features, these collaborative robots can be used without safety barriers if a risk assessment is conducted. They are compact, lightweight, and easy to program, allowing a single robot to be deployed across multiple processes. To lower the barriers to robot adoption, Universal Robots offers free online training and has a rich ecosystem of peripheral devices. If you are struggling with labor shortages, please consider our solutions. Many customers are utilizing our robots even in environments without robotics engineers.

![[e-Book] "10 Steps for Introducing Collaborative Robots for First-Time Users"](https://image.mono.ipros.com/public/catalog/image/01/b2a/446367/IPROS15561473372210836574.jpeg?w=120&h=170)

![[Collaborative Robot Implementation Case] Interview with the President of Tanoi Manufacturing Co., Ltd.](https://image.mono.ipros.com/public/product/image/bff/2001484581/IPROS7364194513464324982.png?w=280&h=280)